Well-designed Mg6 Spare Parts Wholesale - Factory price SAIC MAXUS V80 C00014635 Oil Pan – Country IV – Zhuomeng

Well-designed Mg6 Spare Parts Wholesale - Factory price SAIC MAXUS V80 C00014635 Oil Pan – Country IV – Zhuomeng Detail:

Products information

| Products name | Oil Pan |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C00014635 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Power system |

Products knowledge

wet

Wet Sump

oil pan

Most of the cars seen on the market are wet oil pans. The reason why they are named wet oil pans is that the crankshaft crankshaft and the big end of the connecting rod of the engine are immersed in the lubricating oil of the oil pan once every revolution of the crankshaft. At the same time, due to the high-speed operation of the crankshaft, each time the crankshaft is immersed in the oil pool at high speed, certain oil splashes and oil mists will be aroused to lubricate the crankshaft and the bearing bush, which is called splash lubrication. In this way, there are certain requirements for the liquid level of the lubricating oil in the oil pan. If it is too low, the crankshaft crankshaft and the big end of the connecting rod cannot be immersed in the lubricating oil, resulting in a lack of lubrication and smooth crankshaft, connecting rod and bearing bush. ; If the lubricating oil level is too high, the bearing will be immersed in the whole, which will increase the rotation resistance of the crankshaft, which will eventually lead to the decline of the engine performance.

This kind of lubrication method has a simple structure and does not require an additional oil tank, but the inclination of the vehicle should not be too large, otherwise it will cause a burning oil cylinder accident due to oil failure and oil leakage.

dry

Dry Sump

Dry sumps are used in many racing engines. It does not store oil in the sump, more precisely, no oil sump. The friction surfaces of these movements in the crankcase are lubricated by pressing out oil through one by one orifice. Since the dry sump engine cancels the oil storage function of the oil sump, the height of the crude oil sump is greatly reduced, and the height of the engine is also reduced. The main advantage is that it avoids the adverse phenomena of wet sump caused by intense driving.

However, all the pressure of the lubricating oil comes from the oil pump. The power of the oil pump is connected by gears through the rotation of the crankshaft. Although in a wet sump engine, an oil pump is also required to provide pressure lubrication for the camshaft. But this pressure is small, and the oil pump needs very little power. In dry sump engines, however, the strength of this pressure lubrication needs to be much greater. And the size of the oil pump is also much larger than the oil pump of the wet sump engine. Therefore, the oil pump needs more power at this time. This is like a supercharged engine, the oil pump needs to consume part of the engine’s power. Especially at high speed, when the engine speed increases, the motion intensity of friction parts increases, and more oil is needed for lubrication, so the oil pump needs to provide more pressure, and the consumption of crankshaft power is also intensified.

Obviously, such a design is not suitable for ordinary civil vehicle engines, because it needs to lose a part of the power of the engine, which not only affects the power output, but also is not conducive to improving the economy. Therefore, the dry sump is only equipped with large displacement or high-power engines, such as those sports cars that are born for intense driving. For example, Lamborghini adopts the design of dry oil sump. For it, it is more important to improve the lubrication effect at the limit and obtain a lower center of gravity, and the loss of power can be compensated by increasing the displacement and other aspects. As for the economy Sexuality is something this model does not need to consider at all.

Operation and maintenance

The fuel injection pump is an important part of the diesel generator fuel supply system, and its working condition directly affects the power, economy and reliability of the diesel generator. Correct maintenance is an important prerequisite to ensure the normal operation of the fuel injection pump and prolong its service life. The following “ten elements” teach you how to maintain the fuel injection pump of diesel generators:

1. To properly maintain the accessories of the fuel injection pump.

The side cover of the pump body, oil dipstick, refueling plug (respirator), oil spill valve, oil pool screw plug, oil level screw, oil pump fixing bolt, etc. must be kept intact. These accessories play a vital role in the operation of the fuel injection pump. important role. For example, the side cover can prevent the intrusion of impurities such as dust and water, the respirator (with a filter) can effectively prevent the deterioration of the oil, and the oil overflow valve ensures that the fuel system has a certain pressure and does not enter the air. Therefore, it is necessary to strengthen the maintenance of these accessories, and repair or replace them in time if they are damaged or lost.

2. Regularly check whether the oil quantity and quality in the oil pool of the fuel injection pump meet the requirements.

Before starting the diesel generator, the quantity and quality of the oil in the fuel injection pump should be checked each time (except for the fuel injection pump that is forced to lubricate by the engine) to ensure that the quantity of the oil is sufficient and the quality is good. Otherwise, it will cause the early wear of the plunger and the oil outlet valve pair, resulting in insufficient power of the diesel engine, difficulty in starting, and in severe cases, corrosion and corrosion of the plunger and the oil outlet valve pair. Due to internal leakage of the oil pump, poor operation of the oil outlet valve, wear of the tappet and the casing of the oil transfer pump, and damage to the sealing ring, diesel oil will leak into the oil pool and dilute the oil. Therefore, it should be replaced in time according to the quality of the oil. The tank is thoroughly cleaned to remove the sludge and other impurities at the bottom of the oil tank, otherwise the oil will deteriorate after a short time of use. The amount of oil should not be too much or too little. Too much oil in the governor will easily lead to “speeding” of the diesel engine. Too little oil will cause poor lubrication. The oil dipstick or the oil plane screw shall prevail. In addition, when the diesel engine is not used for a long time, it is necessary to check whether there are impurities such as water and diesel oil in the oil in the oil pump oil pool. Pieces rusted stuck and scrapped.

3. Regularly check and adjust the fuel supply of each cylinder of the fuel injection pump.

Due to the wear of the plunger coupler and the oil outlet valve coupler, the internal leakage of diesel oil will cause the fuel supply of each cylinder to be reduced or uneven, resulting in difficulty in starting the diesel engine, insufficient power, increased fuel consumption, and unstable operation. Therefore, it is necessary to regularly check and adjust the fuel supply of each cylinder of the fuel injection pump to ensure the performance of the diesel engine power. In actual use, the fuel supply amount of each cylinder can be determined by observing the exhaust smoke of the diesel generator, listening to the sound of the engine, and touching the temperature of the exhaust manifold.

4. Use standard high-pressure oil pipes.

During the fuel supply process of the fuel injection pump, due to the compressibility of diesel oil and the elasticity of the high-pressure oil pipe, the high-pressure diesel oil will form pressure fluctuations in the pipe, and it takes a certain time for the pressure wave to transmit in the pipe. The amount is uniform, the diesel engine works smoothly, and the length and diameter of the high-pressure oil pipe are selected after calculation. Therefore, when the high-pressure oil pipe of a certain cylinder is damaged, the oil pipe of standard length and pipe diameter should be replaced. In actual use, due to the lack of standard oil pipes, other oil pipes are used instead, regardless of whether the length and diameter of the oil pipes are the same, so that the length and diameter of the oil pipes are very different. Although it can be used in an emergency, it will lead to the oil supply of the cylinder. The change of advance angle and oil supply amount makes the whole machine work unstable, so standard high-pressure oil pipe must be used in use.

5. Regularly check the sealing condition of the valve coupler on the machine.

After the fuel injection pump works for a period of time, by checking the sealing condition of the fuel outlet valve, a rough judgment can be made on the wear of the plunger and the working condition of the fuel pump, which is beneficial to determine the repair and maintenance method. When checking, unscrew the high-pressure oil pipe joints of each cylinder, and use the hand oil pump of the oil delivery pump to pump oil. If oil flows out of the oil pipe joints at the top of the fuel injection pump, it means that the oil outlet valve is not well sealed (of course, if the oil outlet valve spring is broken, it will also If this happens), if there is a bad seal in the multi-cylinder, the fuel injection pump should be thoroughly debugged and maintained, and the coupler should be replaced.

6. Replace the worn plunger and oil outlet valve pair in time.

When it is found that the diesel engine is difficult to start, the power decreases, and the fuel consumption increases, and the fuel injection pump and fuel injector are still not improved by adjusting the fuel injection pump, the fuel injection pump plunger and the fuel outlet valve should be disassembled and inspected. If the plunger and the fuel outlet valve are worn to a certain extent degree, should be replaced in time, do not insist on reuse. Diesel engine start-up difficulties, increased fuel consumption, insufficient power and other losses caused by the wear of the coupling parts far exceed the cost of replacing the coupling parts, and the power and economy of the diesel engine will be significantly improved after replacement. Replacement parts.

7. The diesel oil should be used and filtered properly to ensure that the diesel oil entering the fuel injection pump is highly clean.

Generally speaking, diesel generators have much higher requirements for diesel filtration than gasoline engines. Diesel oils that meet the required grades should be selected for use, and they should be precipitated for at least 48 hours. Strengthen the cleaning and maintenance of the diesel filter, clean or replace the filter element in time; clean the diesel tank in time according to the operating environment conditions, thoroughly remove the sludge and moisture at the bottom of the fuel tank, and any impurities in the diesel will affect the plunger of the fuel injection pump and the oil output. Serious corrosion or wear of valve couplers and transmission parts.

8. Regularly check and adjust the fuel supply advance angle of the fuel injection pump and the fuel supply interval angle of each cylinder.

During use, due to the loosening of the coupling bolts and the wear of the camshaft and roller body parts, the advance angle of oil supply and the oil supply interval angle of each cylinder are often changed, which makes the diesel combustion worse, and the power and economy of the diesel engine. The performance deteriorates, and at the same time, it is difficult to start, unstable in operation, abnormal noise and overheating. In actual use, most drivers pay attention to the inspection and adjustment of the overall fuel supply advance angle, but ignore the inspection and adjustment of the fuel supply interval angle (involving the adjustment of the single pump fuel supply advance angle). However, due to the wear of camshafts and roller transmission parts, the oil supply of the remaining cylinders is not necessarily timing, which will also lead to difficulty in starting the diesel engine, insufficient power, and unstable operation, especially for the fuel injection pump that has been used for a long time. It is said that more attention should be paid to the inspection and adjustment of the oil supply interval angle.

9. To regularly check the camshaft clearance.

The axial clearance of the camshaft of the fuel injection pump is very strict, generally between 0.03 and 0.15mm. If the clearance is too large, it will aggravate the impact of the roller transmission parts on the working surface of the cam, thereby increasing the early wear of the cam surface and changing the supply. Oil advance angle; The camshaft bearing shaft and radial clearance are too large, which is easy to cause the camshaft to run unevenly, the oil volume adjustment lever shakes, and the oil supply volume changes periodically, which makes the diesel engine run unstable, so it is necessary to check and adjust regularly. When the axial clearance of the camshaft is too large, shims can be added on both sides for adjustment. If the radial clearance is too large, it is generally necessary to replace the new product.

10. Regularly check the wear of the relevant keyways and fixing bolts.

Relevant keyways and bolts mainly refer to camshaft keyways, coupling flange keyways (oil pumps that transmit power with couplings), semicircular keys and coupling fixing bolts. The camshaft keyway, flange keyway and semicircular key of the fuel injection pump have been used for a long time, and the light ones are worn out, which makes the keyway wider, the semicircular key is not installed firmly, and the advance angle of oil supply changes; in the severe case, the key rolls off, resulting in failure of power transmission. , so it is necessary to check regularly and repair or replace worn parts in time.

Precautions

Diesel Incentives

1. The O-ring of the injector is damaged;

2. Poor atomization of the injector, dripping oil;

3. Improper installation of the injector;

4. The O-ring was not replaced when the injector was reinstalled.

Cummins generator storage should pay attention to:

1) The storage location of the fuel tank must be safe to prevent fire. The fuel tank or oil drum should be placed in a visible place alone, properly away from the diesel generator set, and it is strictly prohibited to smoke.

2) The fuel capacity in the fuel tank should ensure daily daily supply.

3) After the oil tank is placed, the highest oil level cannot be higher than 2.5 meters above the base of the diesel generator set. If the oil level of the large oil depot is higher than 2.5 meters, a daily oil tank should be added between the large oil depot and the unit to make the pressure of direct oil delivery. Not more than 2.5 meters. Even when the diesel engine is turned off, the fuel is not allowed to flow into the diesel engine through the fuel inlet line or the fuel injection line by gravity.

4) The resistance at the oil port is not allowed to exceed the value specified on all diesel engine performance data sheets when using a clean filter element. This resistance value is based on half the fuel in the fuel tank.

5) The fuel return resistance must not exceed the specifications on the performance data sheet of the diesel engine used.

6) The connection of the fuel oil return pipeline should not cause shock waves to appear in the fuel oil pipeline.

OUR EXHIBITION

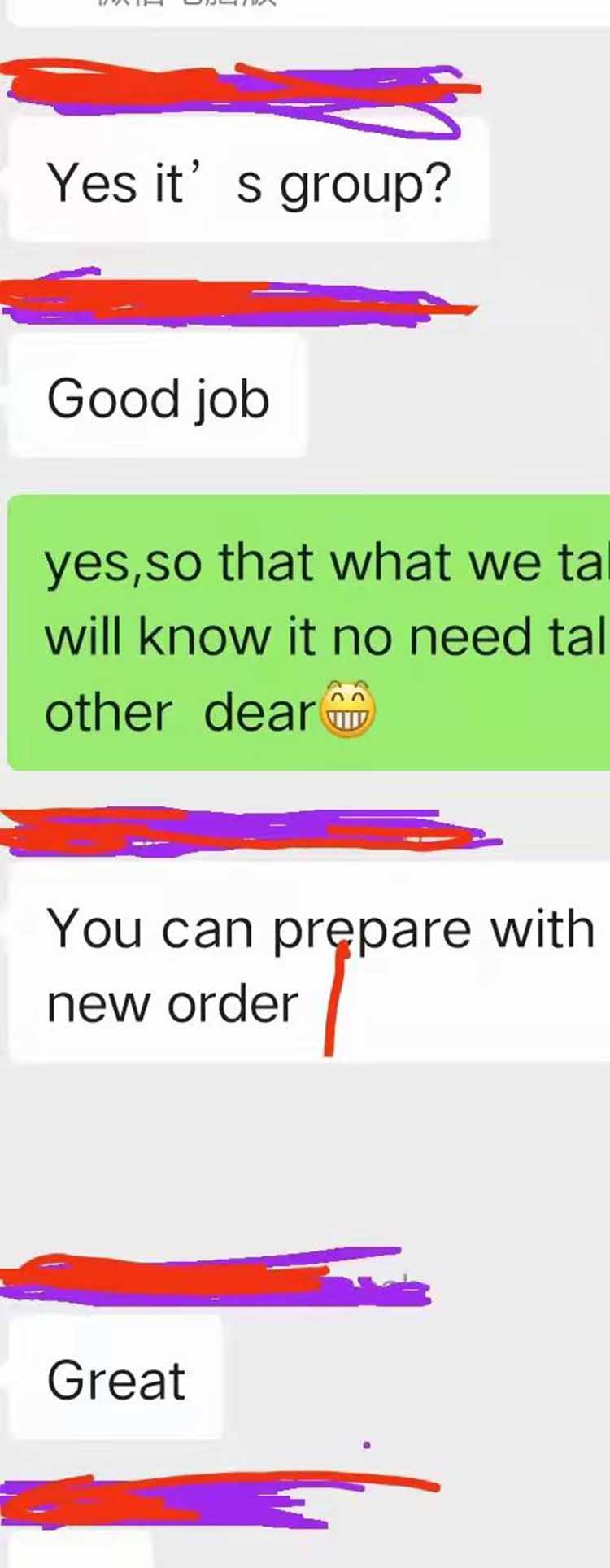

Good Feetback

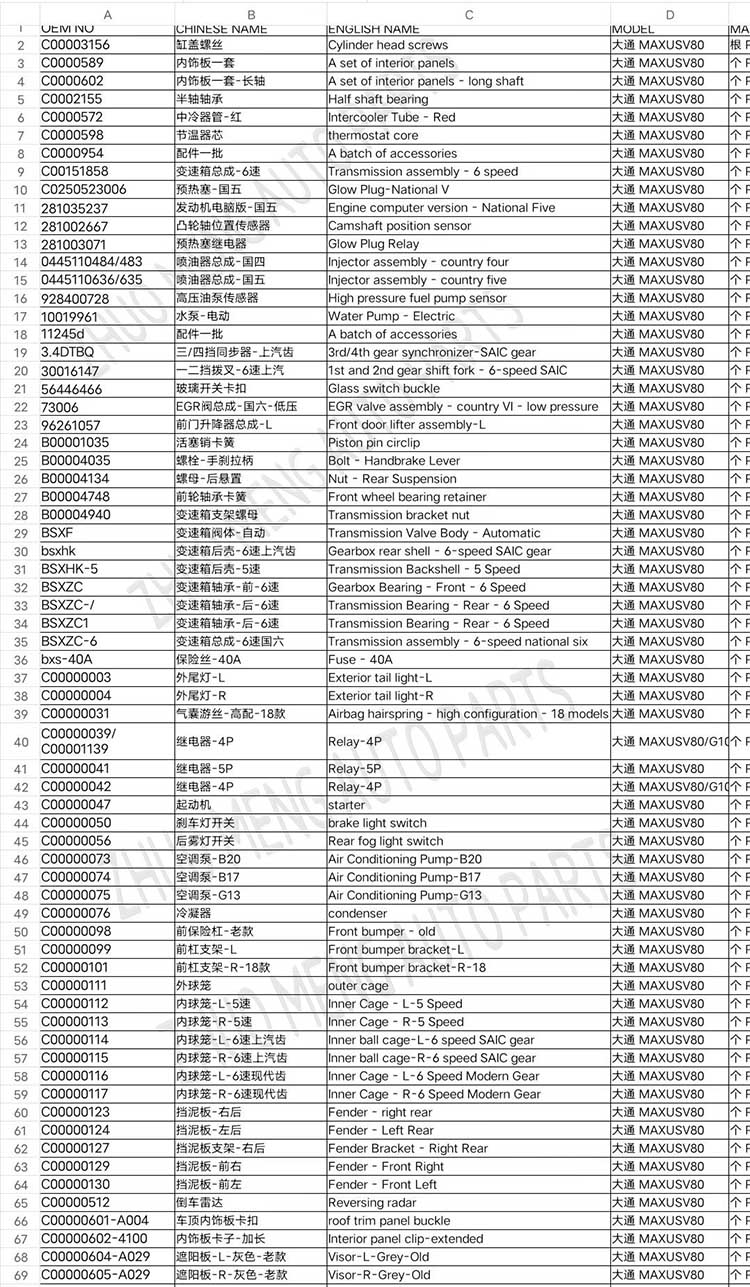

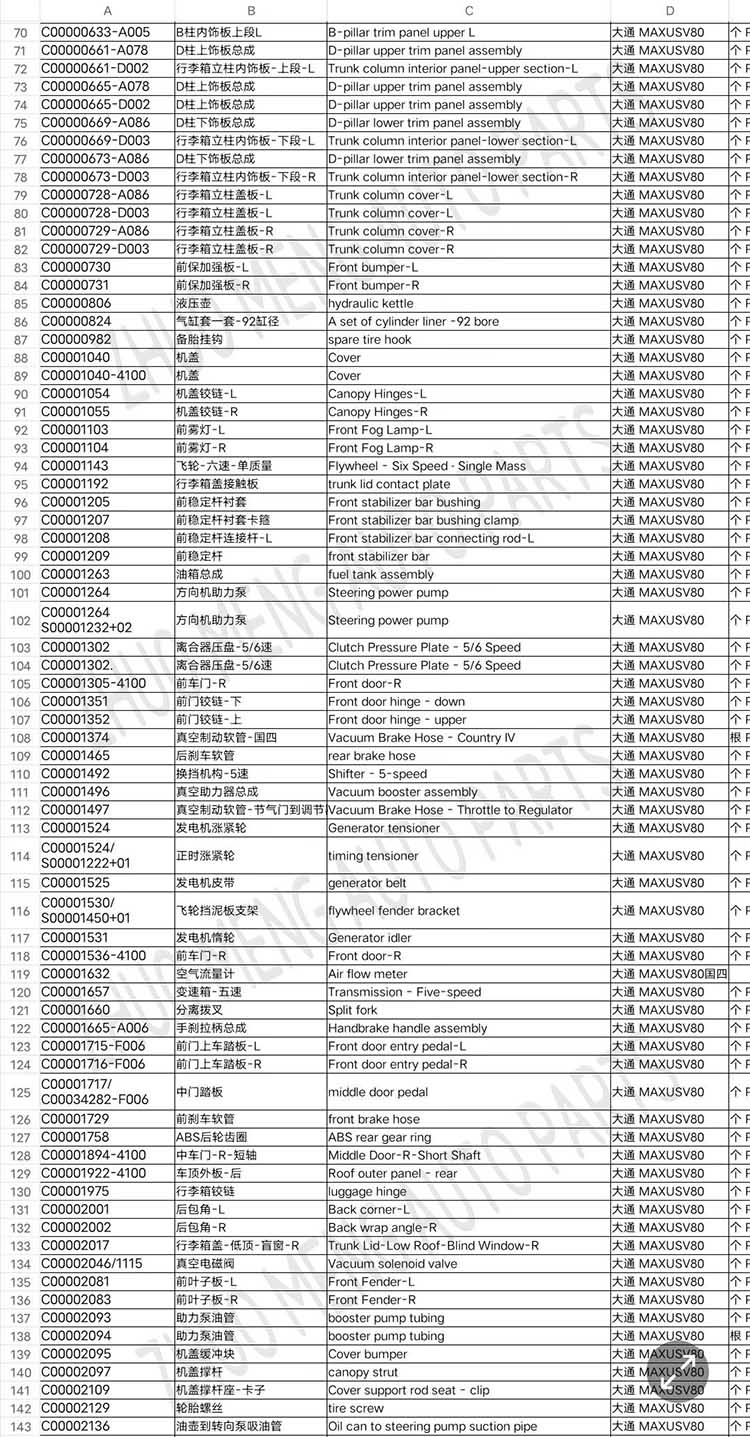

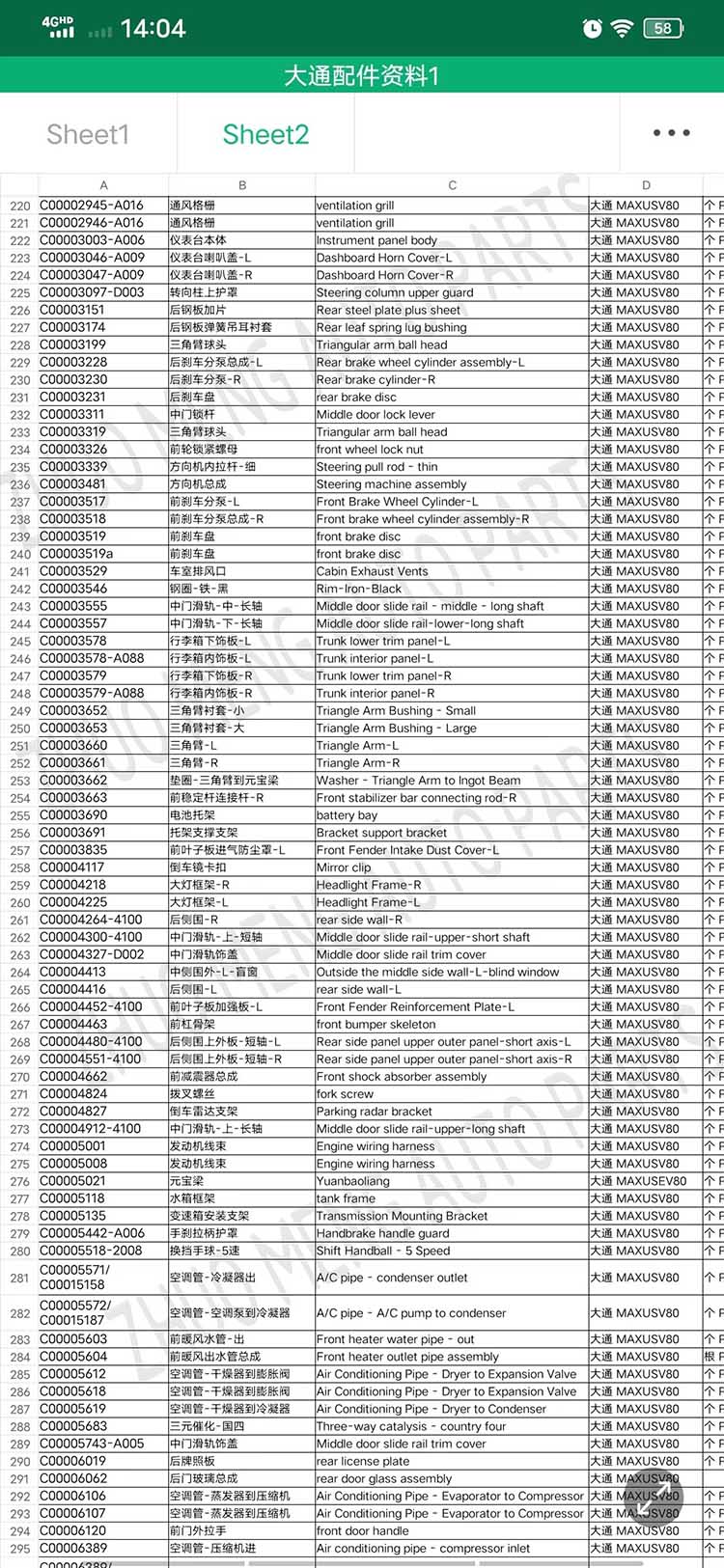

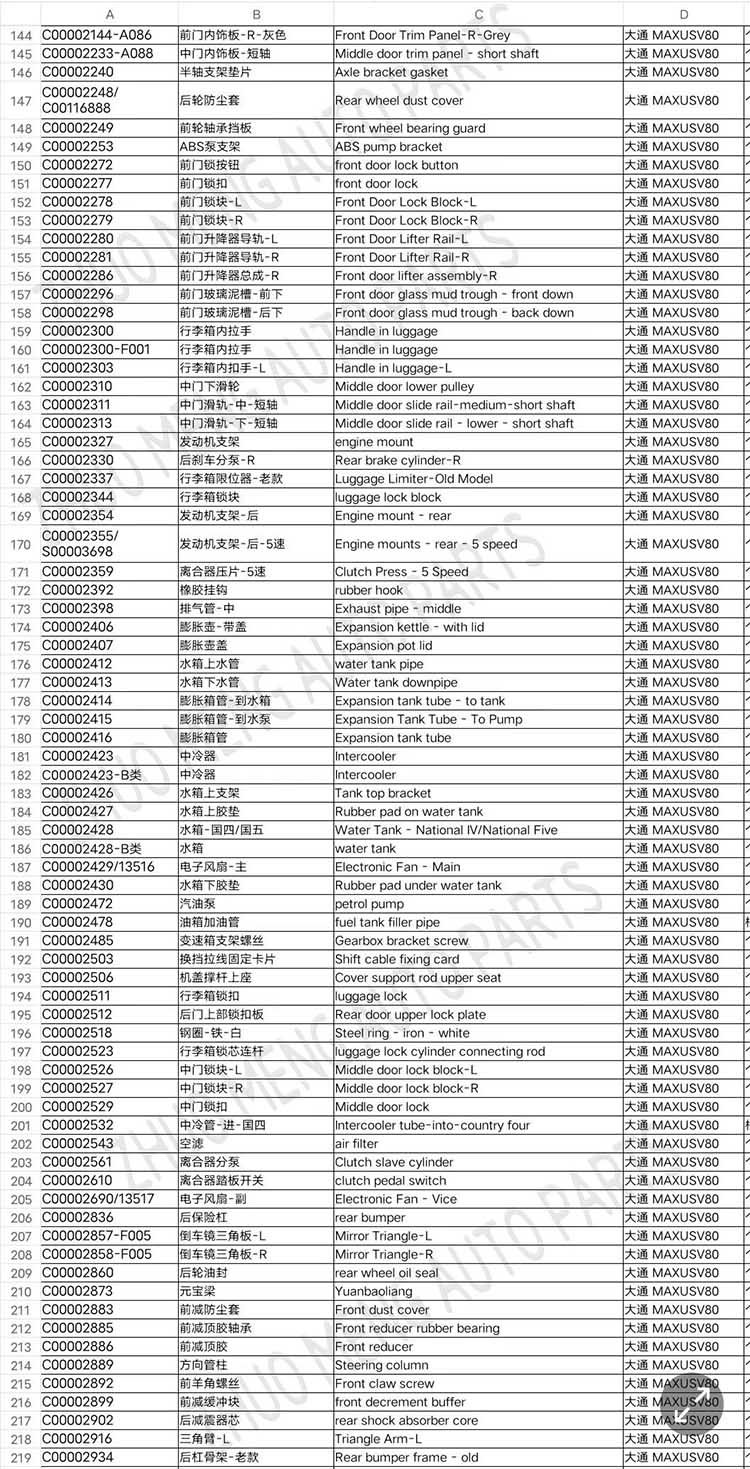

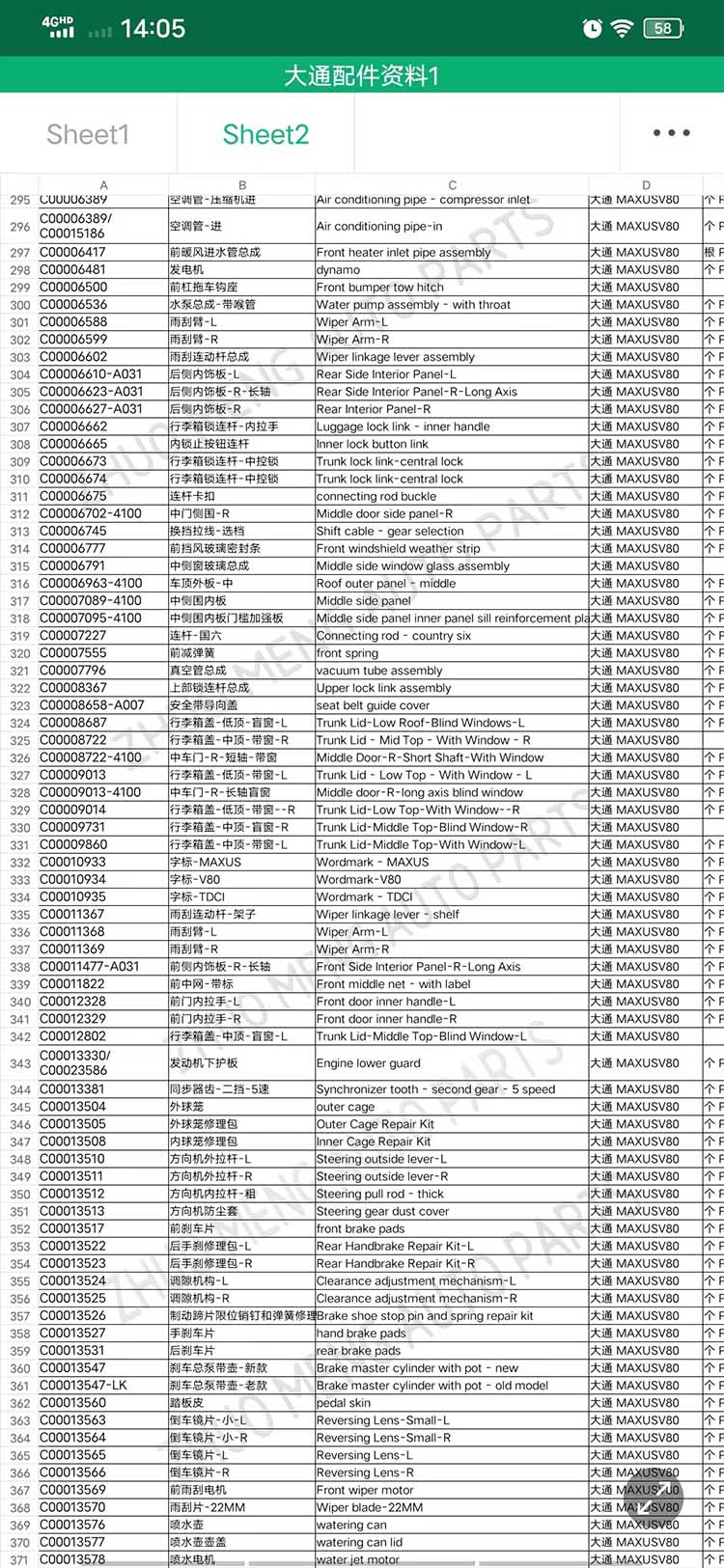

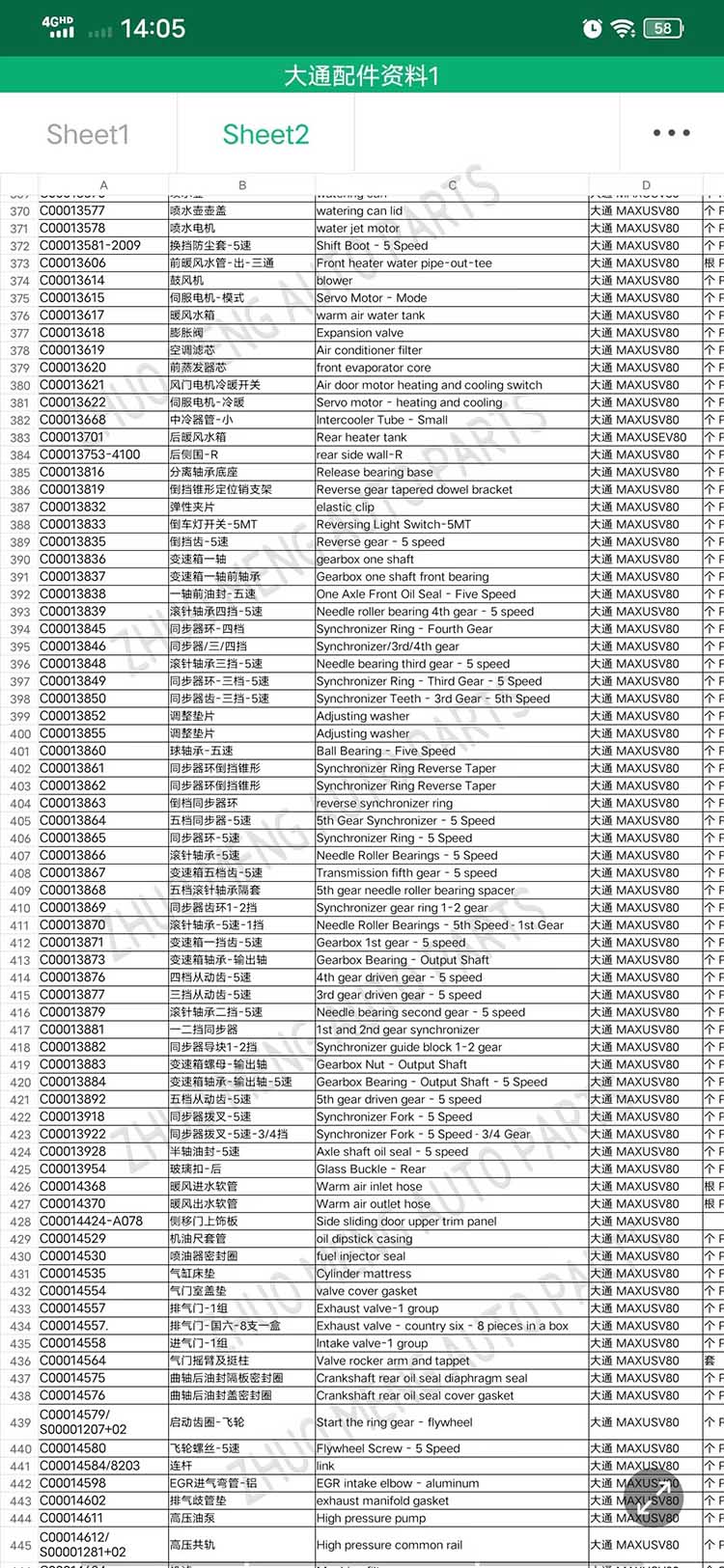

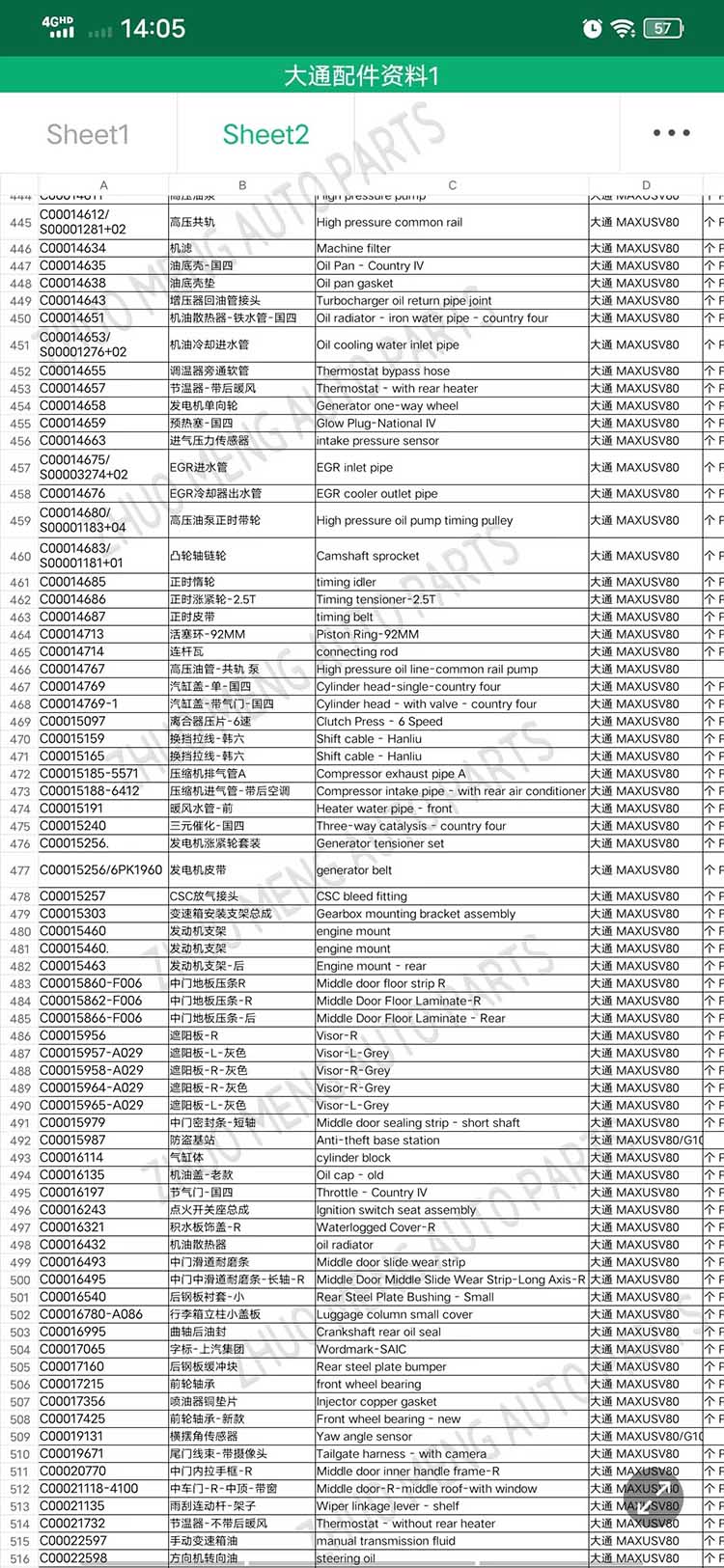

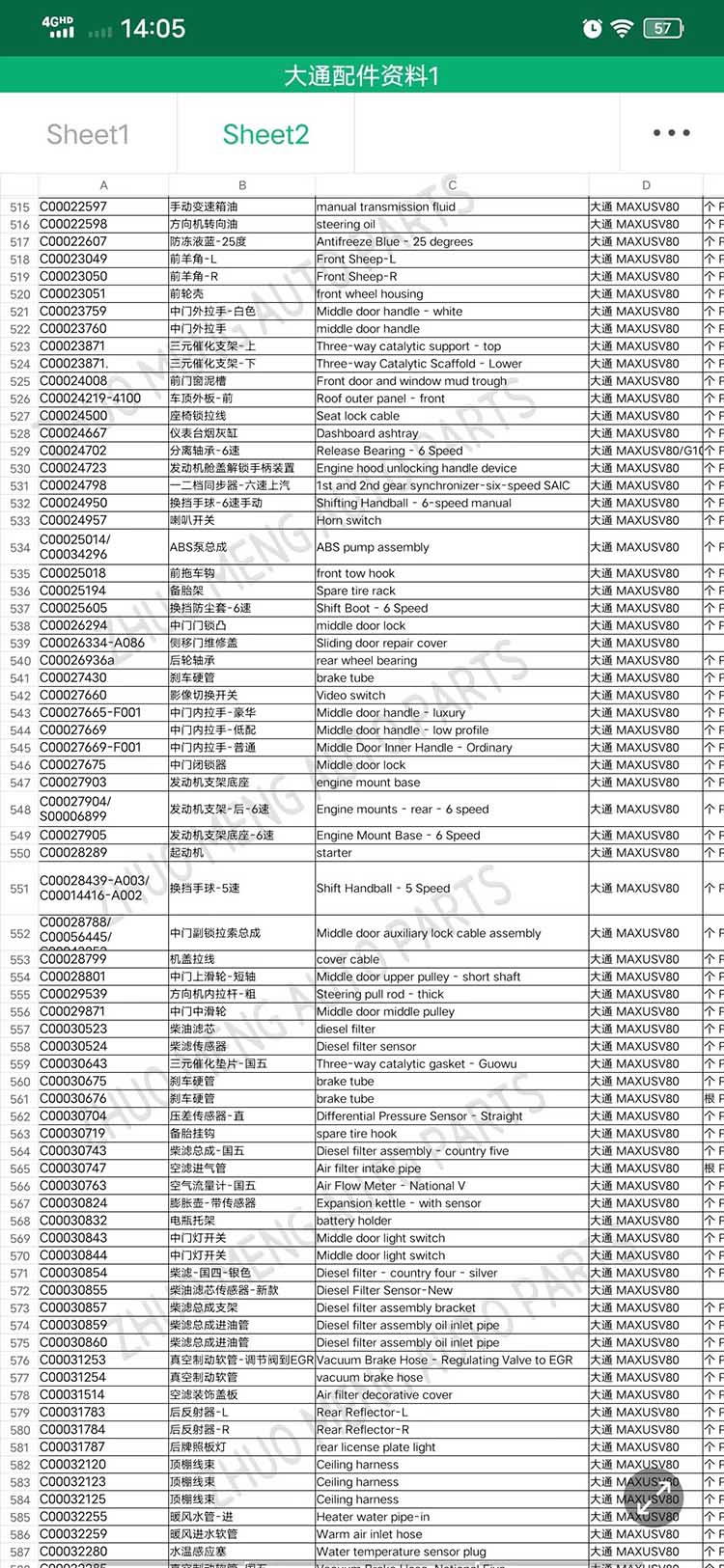

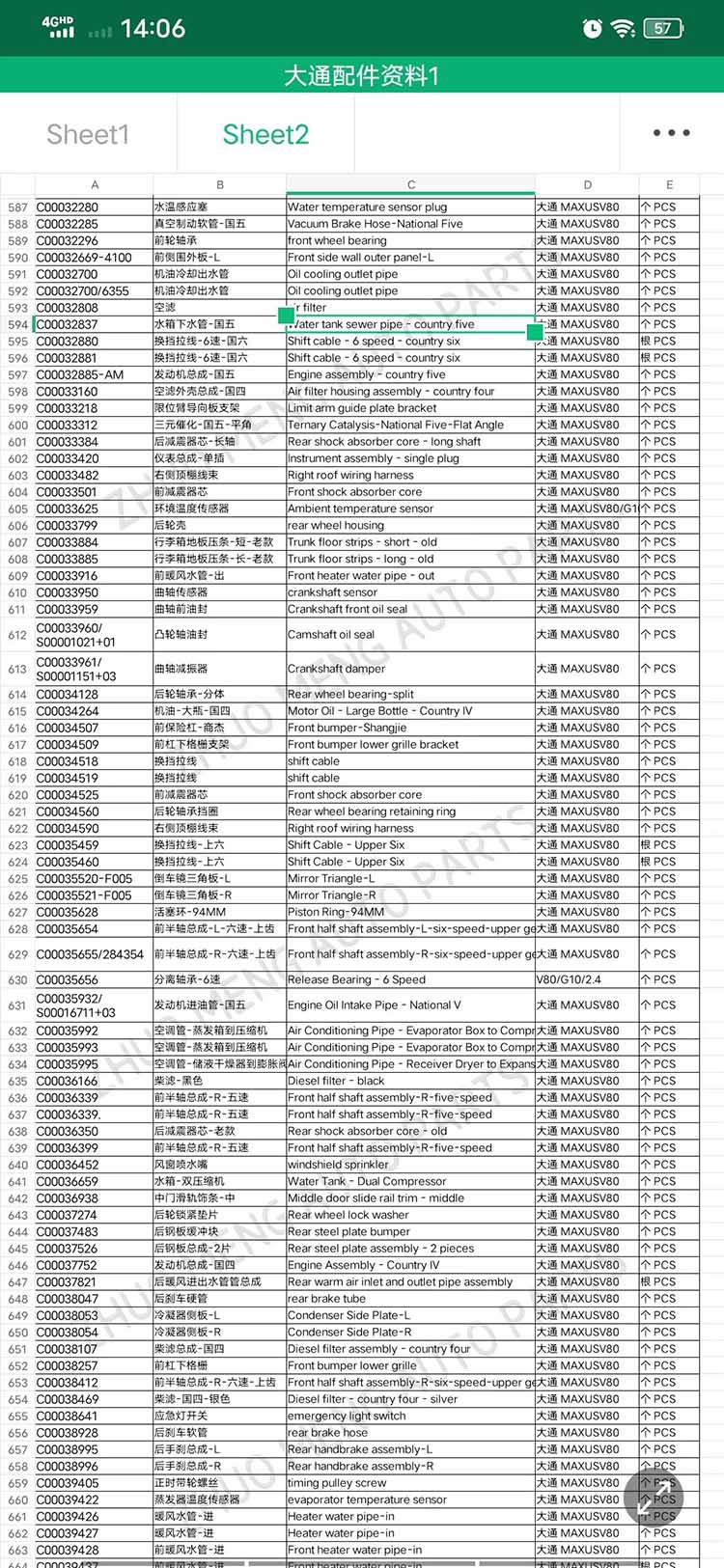

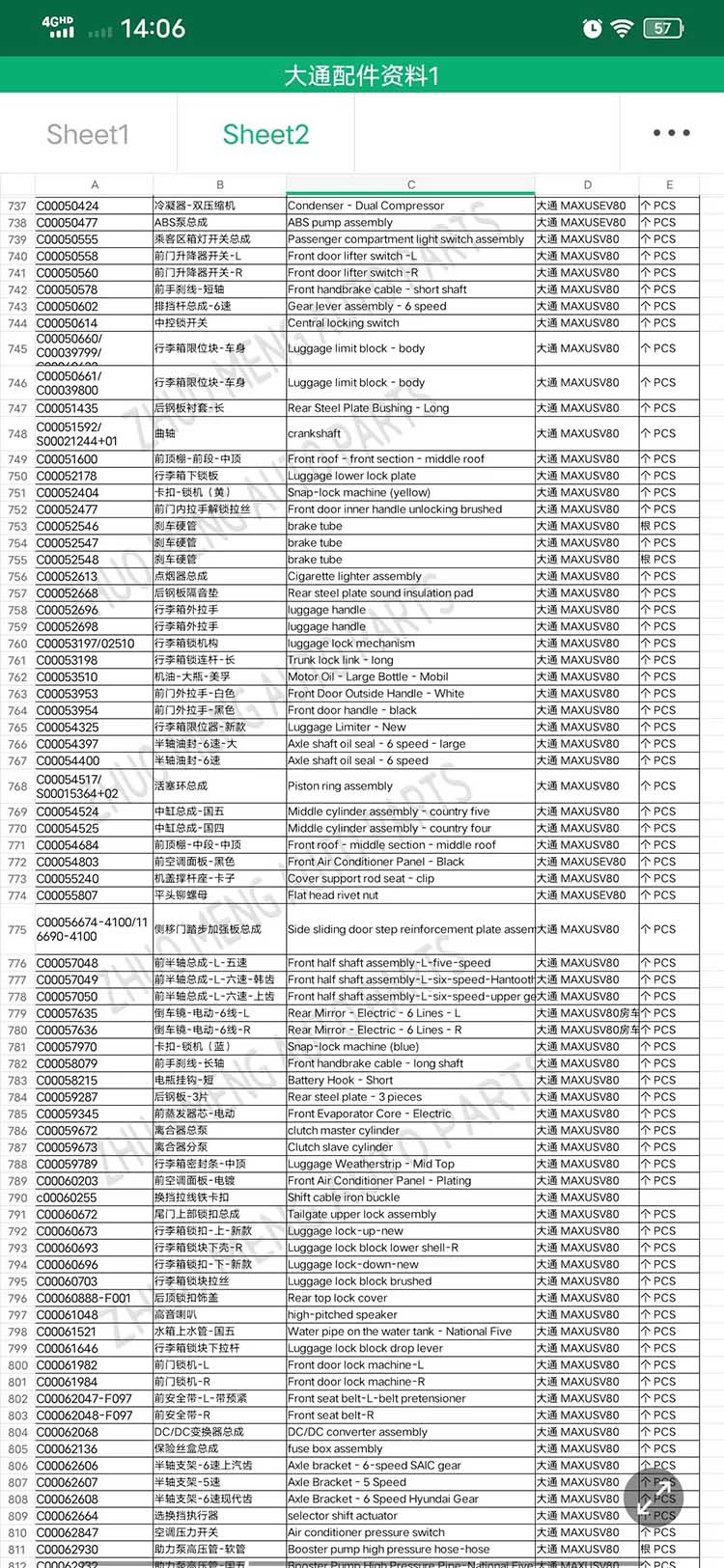

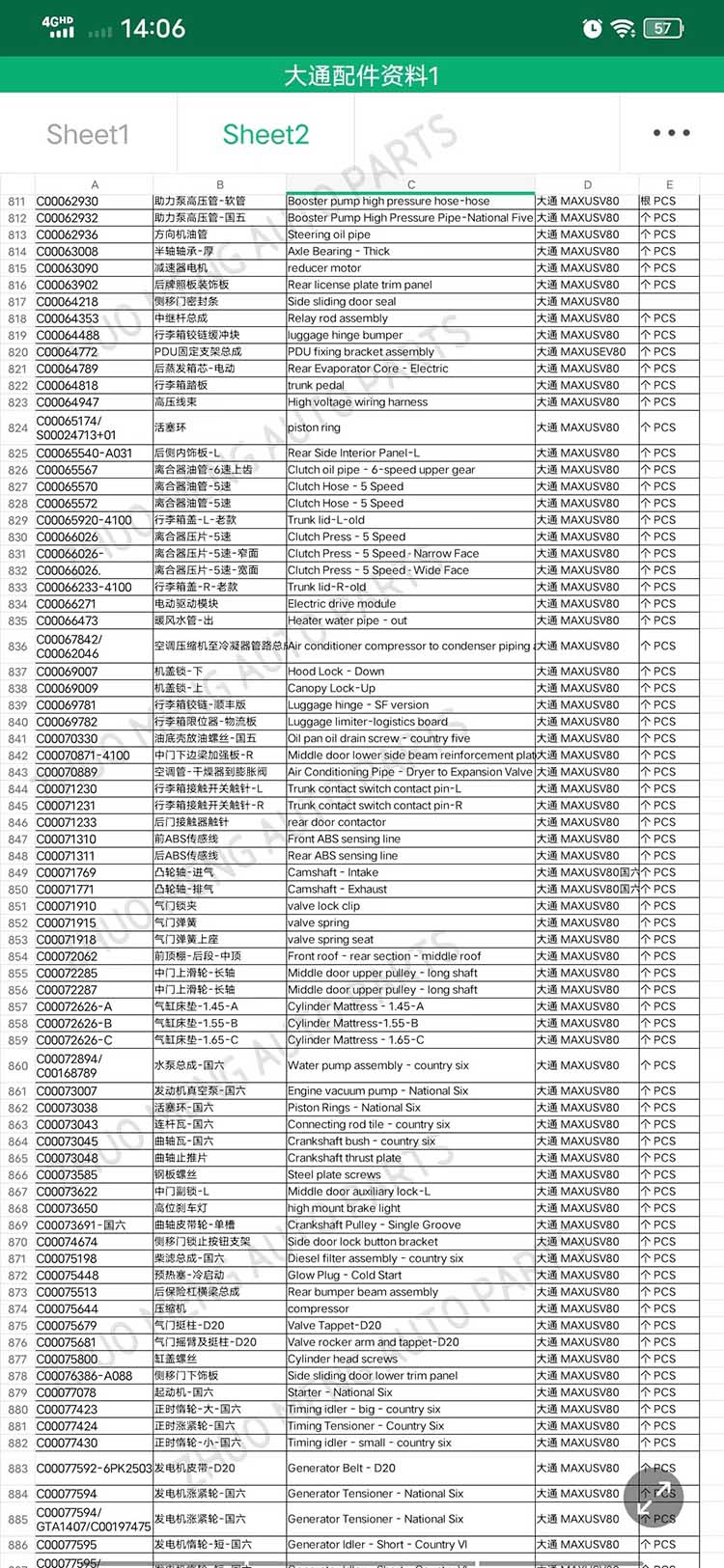

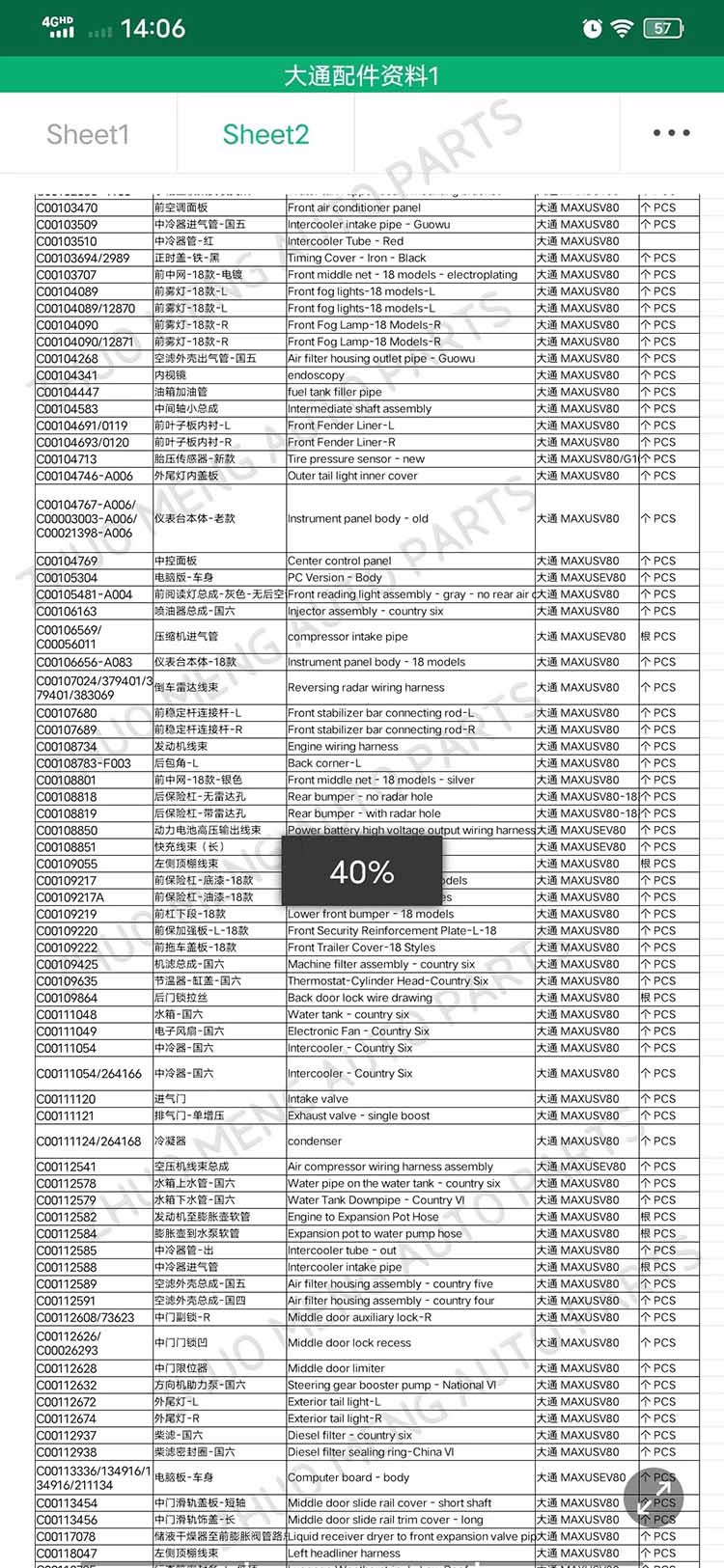

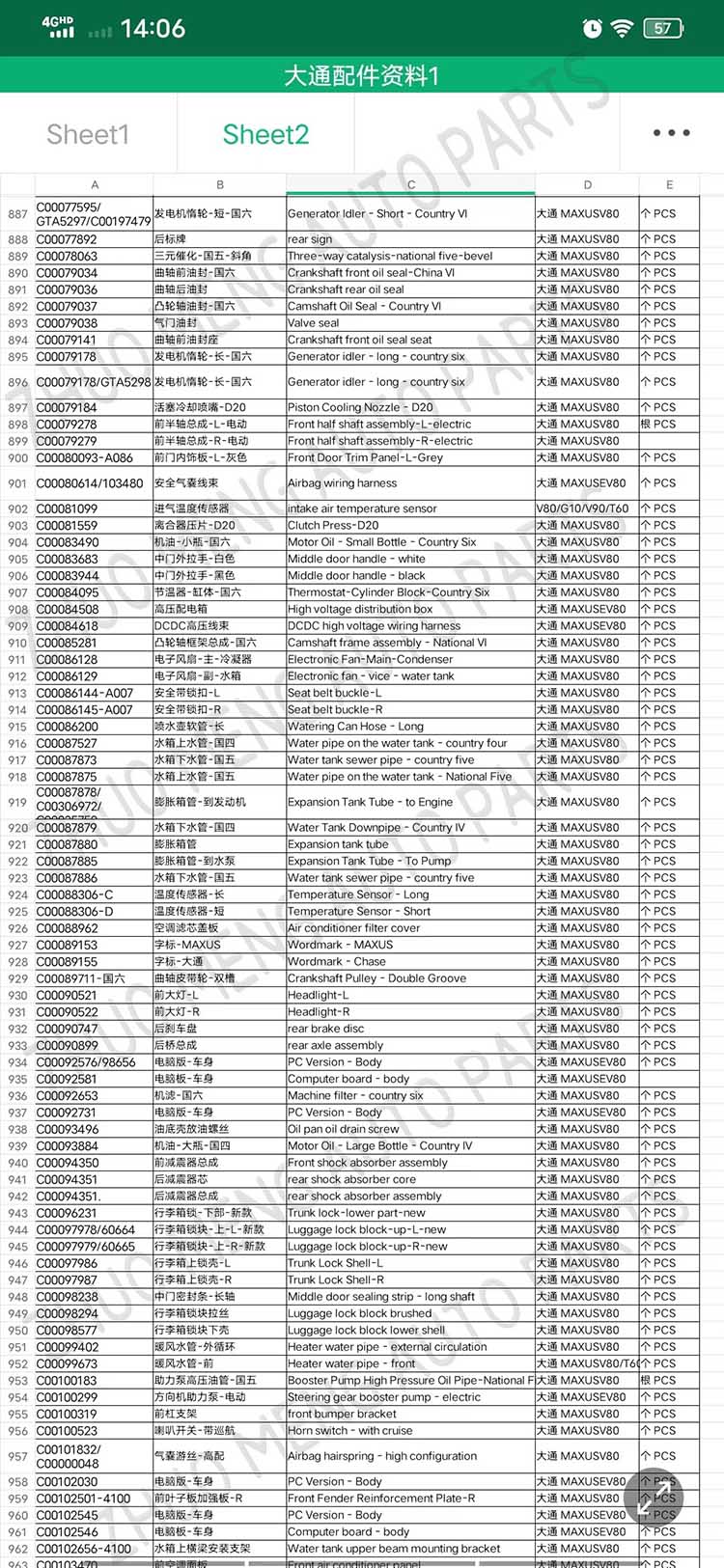

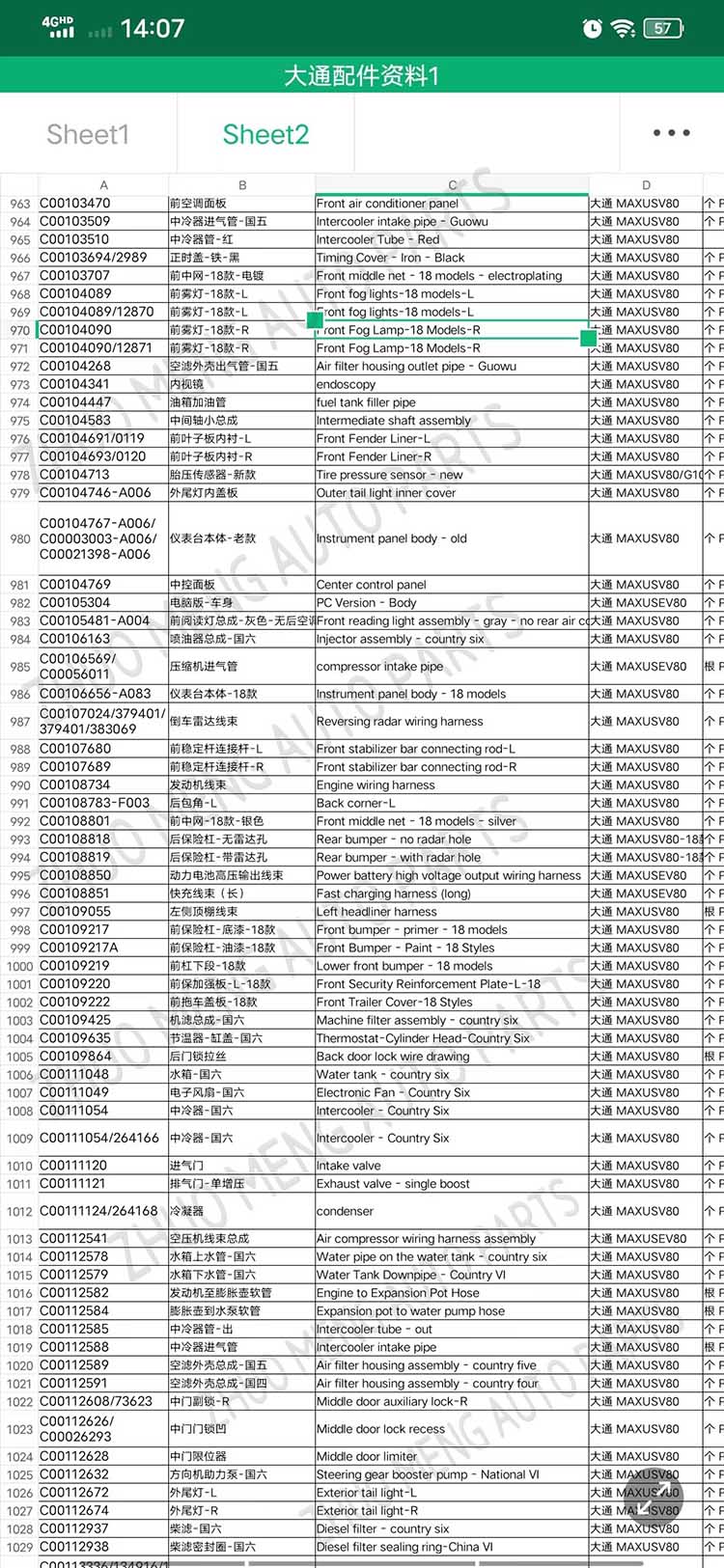

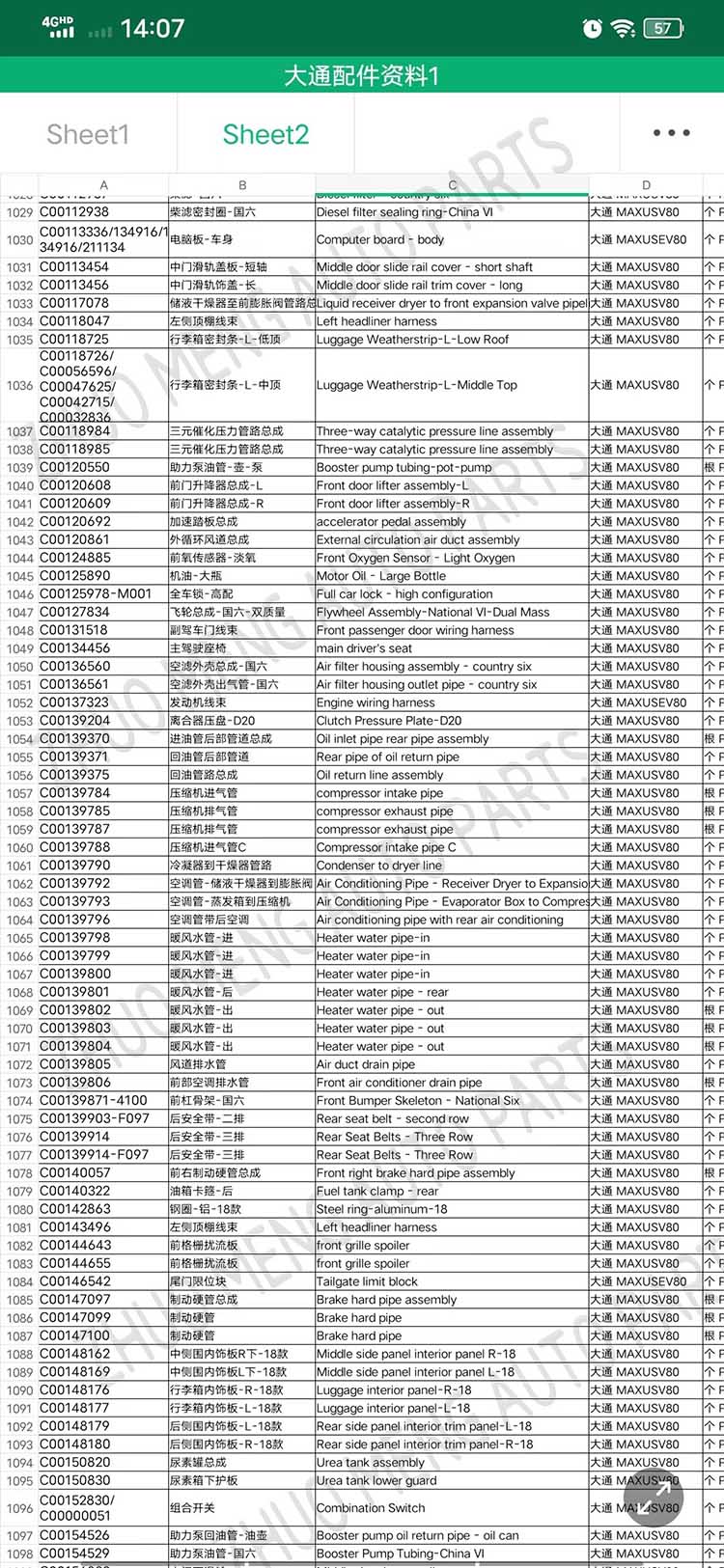

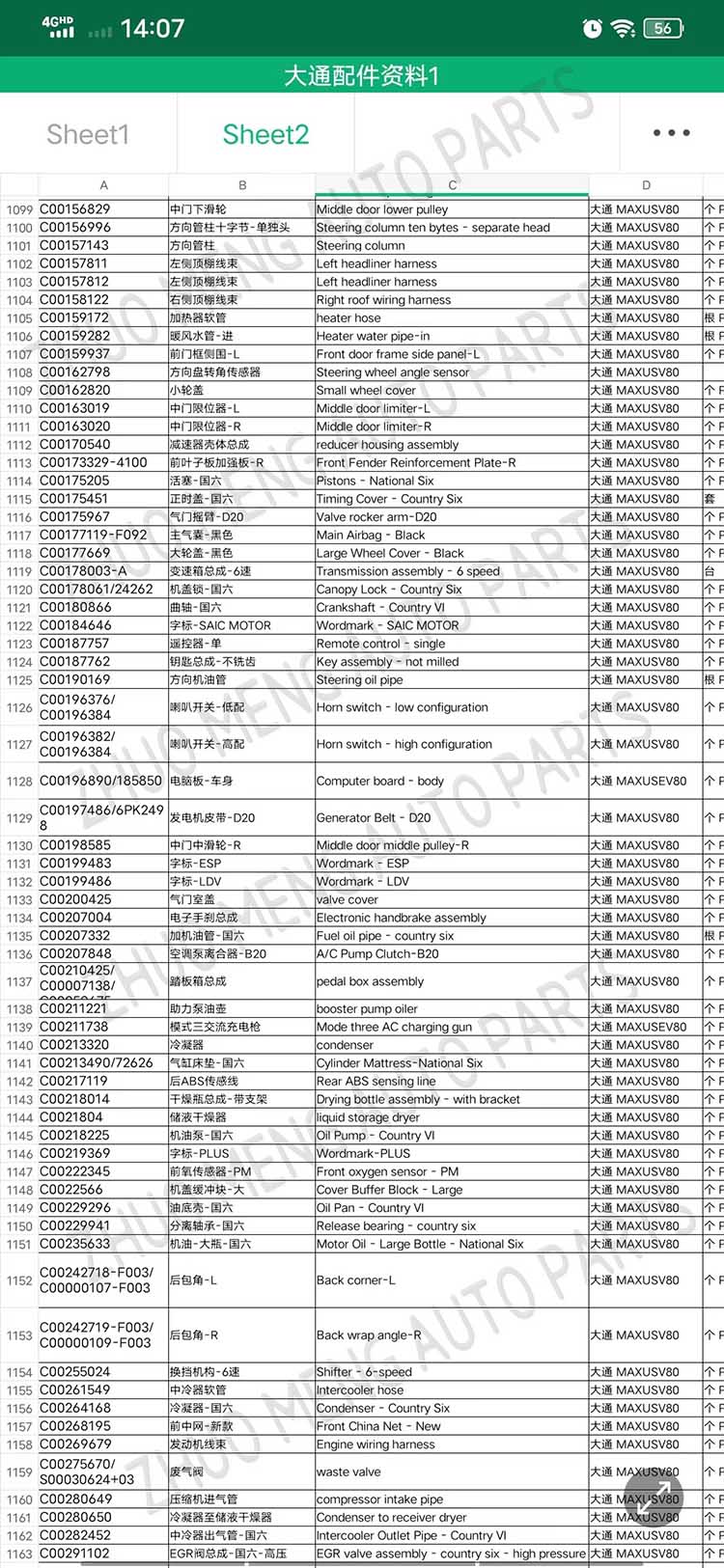

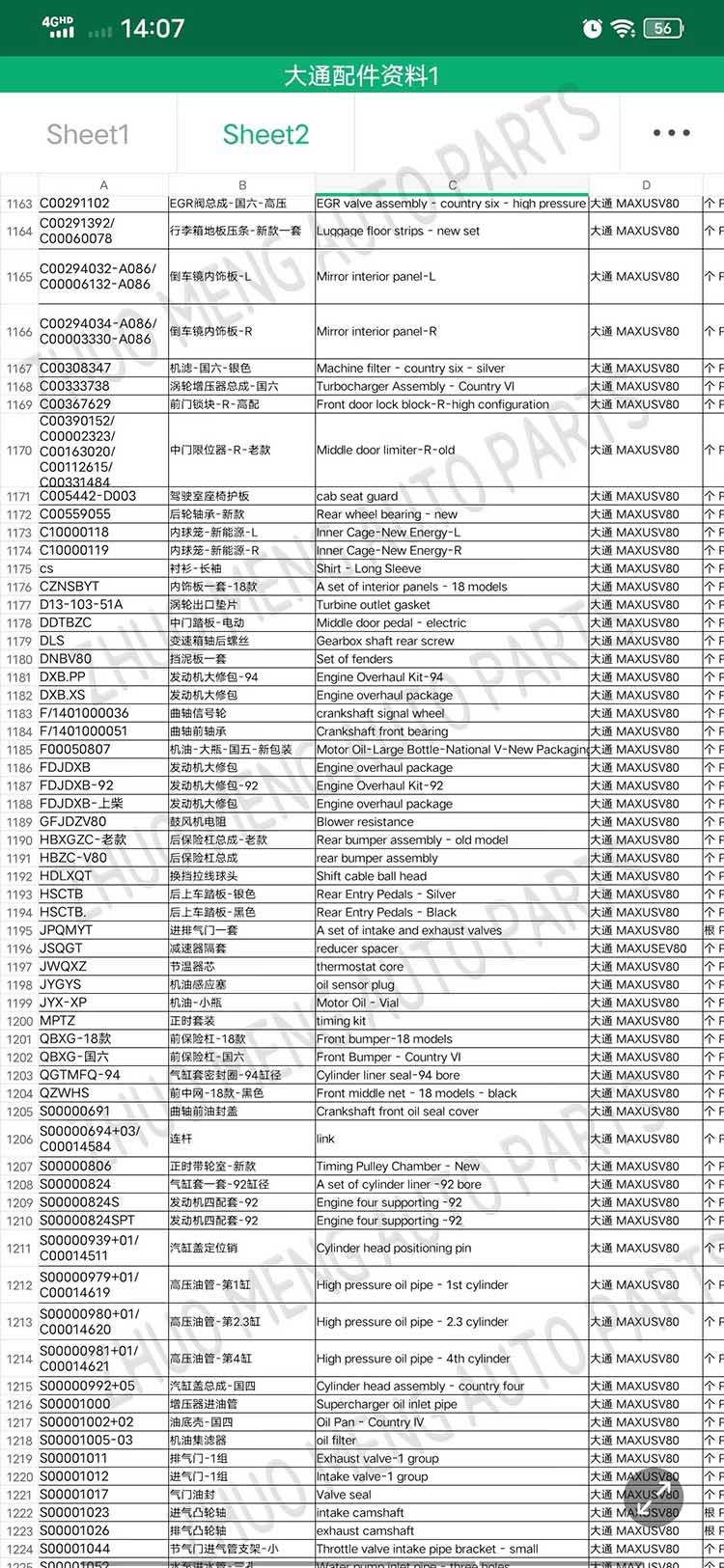

Products catalog

Related products

Product detail pictures:

Related Product Guide:

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for Well-designed Mg6 Spare Parts Wholesale - Factory price SAIC MAXUS V80 C00014635 Oil Pan – Country IV – Zhuomeng , The product will supply to all over the world, such as: Latvia, Mali, Colombia, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.