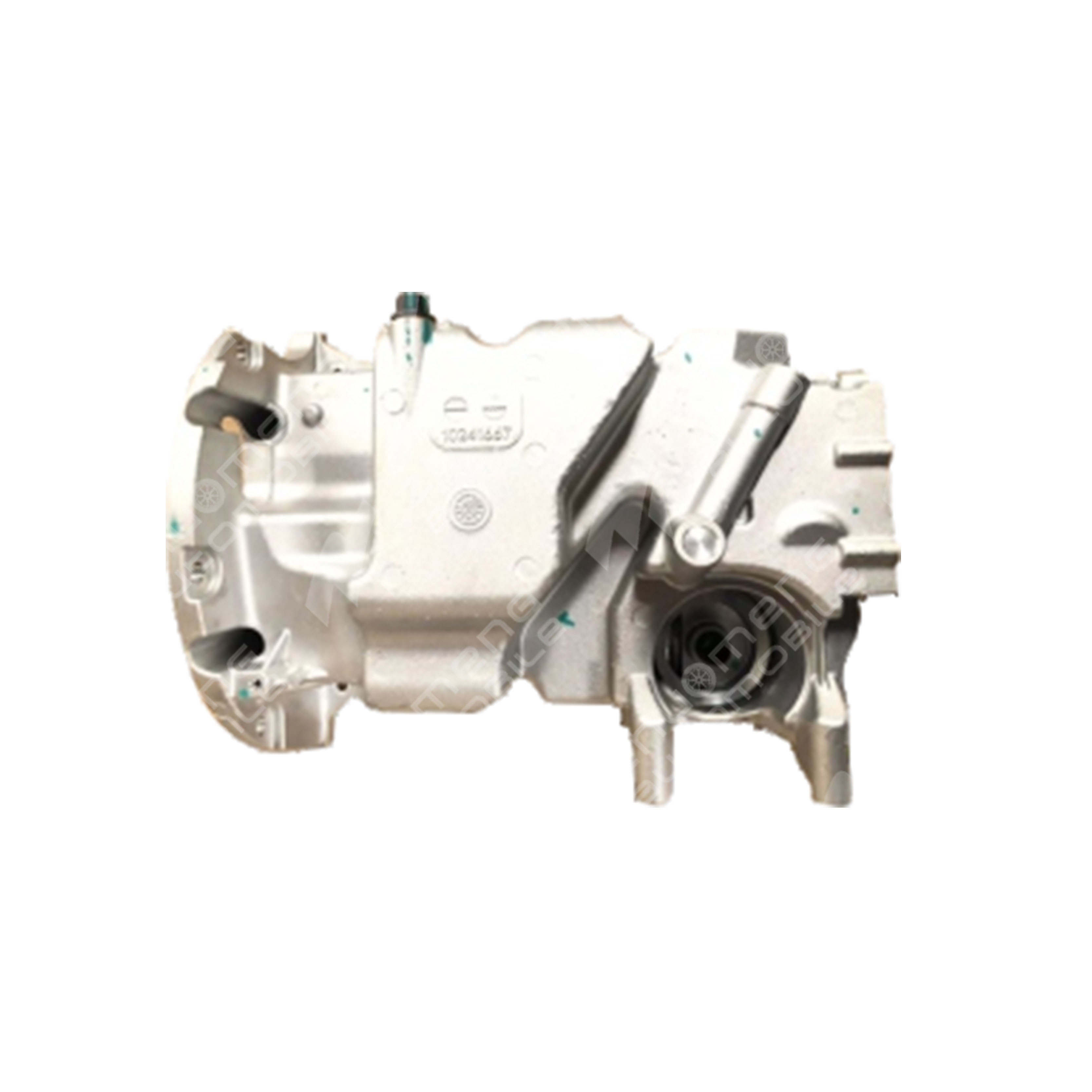

Oil pan.

The oil pan is the lower half of the crankcase, also known as the lower crankcase. The function is to close the crankcase as the shell of the oil storage tank, prevent impurities from entering, and collect and store the lubricating oil flowing back from the friction surface of the diesel engine, dissipate some heat, and prevent the oxidation of lubricating oil.

The Oil Sump is located below the engine: it is removable and seals the crankcase as a housing for the oil tank. The oil pan is mostly made of thin steel plate stamping, and the more complex shape is generally cast cast iron or aluminum alloy. Its internal oil stabilizer baffle is installed to avoid the oil surface shock caused by the diesel engine turbulence splash, which is conducive to the precipitation of lubricating oil impurities, and the side is equipped with an oil gauge to check the oil amount. In addition, the lowest part of the bottom of the oil pan is also equipped with an oil drain plug.

wet-type

Most of the cars on the market are wet oil sump, the reason why it is named wet oil sump is because the crankshaft crank and connecting rod head of the engine will be immersed in the lubricating oil of the oil sump once every rotation of the crankshaft, playing a lubricating role, and because of the high-speed operation of the crankshaft, each time the crank is immersed in the oil pool at high speed, it will stir up certain oil flowers and oil mist. Lubrication of the crankshaft and bearing is called splash lubrication. In this way, the liquid level height of the lubricating oil in the oil pan has certain requirements, if too low, the crankshaft crank and connecting rod head can not be immersed in the lubricating oil, resulting in a lack of lubrication and smooth crankshaft and connecting rod and bearing shell; If the lubricating oil level is too high, it will lead to the entire bearing immersion, so that the crankshaft rotation resistance increases, and ultimately lead to the engine performance decline, while the lubricating oil is easy to enter the cylinder combustion chamber, resulting in engine oil burning, spark plug carbon accumulation and other problems.

This lubrication method is simple in structure and does not require another fuel tank, but the tilt of the vehicle can not be too large, otherwise it will cause a burning cylinder accident due to oil break and oil leakage.

dry-type

Dry sumps are used in many race car engines. It does not store oil in the oil pan, or more precisely, there is no oil pan. These moving friction surfaces in the crankcase are lubricated by pressing out oil through a metering hole. Because the dry oil pan engine cancelling the function of the oil pan to store oil, the height of the crude oil pan is greatly reduced, the height of the engine is also reduced, and the benefit of the lower center of gravity is conducive to control. The main advantage is to avoid the occurrence of wet oil pan those due to intense driving and all kinds of adverse phenomena.

However, because the pressure of the lubricating oil is all from the oil pump. The power of the oil pump is connected by the gear through the rotation of the crankshaft. Although in the wet sump engine although the oil pump is also required to provide pressure lubrication for the camshaft. But this pressure is very small, and the oil pump requires very little power. However, in dry oil pan engines, the strength of this pressure lubrication needs to be much greater. And the size of the oil pump is much larger than that of the wet oil pan engine. So this time the oil pump needs more power. This is like a supercharged engine, the oil pump needs to consume part of the power of the engine. Especially at high speed, the engine speed increases, the motion intensity of the friction parts increases, and the lubricating oil is also required, so the oil pump needs to provide greater pressure, and the consumption of crankshaft power is intensified.

Obviously, such a design is not suitable for ordinary civilian vehicle engines, because it needs to lose part of the engine's power, which will not only affect the power output, but also is not conducive to improving the economy. Dry sumps are therefore only available on high-displacement or high-power engines, such as those built for intense driving. For example, Lamborghini is the use of dry oil pan design, for it, increase the limit of the lubrication effect and obtain a lower center of gravity is more important, and the loss of power can be made up by increasing the displacement and other aspects, as for the economy, is this model does not need to consider.

Fuel injection pump is an important part of fuel supply system of diesel generator. Its working condition directly affects the power, economy and reliability of diesel generator. Correct maintenance is an important prerequisite to ensure the normal operation of fuel injection pump and extend its service life. The following "ten elements" teach you how to maintain the injection pump of a diesel generator:

First, to correctly maintain the injection pump accessories.

Pump side cover, dipstick, fuel plug (breathing apparatus), oil overflow valve, oil pool plug, oil plane screw, oil pump fixing bolt, etc., to ensure intact, these accessories play a vital role in the work of the fuel injection pump. For example, the side cover can prevent the intrusion of dust, water and other impurities, the respirator (with a filter) can effectively prevent oil deterioration, and the oil overflow valve ensures that the fuel system has a certain pressure without entering the air. Therefore, it is necessary to strengthen the maintenance of these accessories, and find that damage or loss should be repaired or replaced in time.

Second, it is necessary to regularly check whether the amount of oil in the fuel injection pump oil pool and its quality meet the requirements.

Each time before starting the diesel generator should check the amount of oil in the injection pump and its quality (except for the injection pump that is forced to be lubricated by the engine), to ensure that the amount of oil is sufficient and the quality is good, if the oil is deteriorated due to mixed with water or diesel, the light will cause the early wear of the plunger and the oil outlet valve, resulting in insufficient power of the diesel engine and difficult to start. In severe cases, it will cause corrosion and rust of the plunger and the oil outlet valve. Due to leakage in the oil pump, poor operation of the oil outlet valve, wear of the tappet and shell of the oil pump, and damage of the sealing ring, the diesel oil will leak into the oil pool and dilute the oil, so it should be replaced in time according to the quality of the oil, and the oil pool should be thoroughly cleaned when replaced, and the impurities such as mud at the bottom of the oil pool will be removed, otherwise the oil will deteriorate in a short time. The amount of oil can not be too much or too little, too much fuel in the governor, easy to lead to the diesel engine "flying", too little fuel will make poor lubrication, should be based on the oil ruler or oil plane screw. In addition, when the diesel engine is not used for a long time, be sure to check whether there is water, diesel and other impurities in the oil pump oil pool, if there is to be replaced immediately, otherwise due to long-term storage, water is easy to make the plunger, the oil valve coupling parts rust and die.

Third, we should regularly check and adjust the oil supply of each cylinder of the injection pump.

Due to the wear and tear of the plunger coupling and the oil valve coupling, the internal leakage of diesel will cause the oil supply of each cylinder to decrease or be uneven, resulting in the difficulty of starting the diesel engine, the lack of power, the increase of fuel consumption, and the instability of operation. Therefore, it is necessary to regularly check and adjust the oil supply of each cylinder of the injection pump to ensure the power of the diesel engine. In actual use, the amount of oil supplied by each cylinder can be determined by observing the exhaust smoke of the diesel generator, listening to the engine sound, and touching the exhaust manifold temperature.

Four, to use standard high-pressure tubing.

Fuel injection pump in the oil supply process, due to the compressibility of diesel oil, the elasticity of high-pressure tubing, high-pressure diesel will form pressure fluctuations in the tube, the pressure wave transfer in the tube takes a certain time, in order to ensure that the cylinder oil supply interval Angle is consistent, the oil supply is uniform, the diesel engine works smoothly, the length and diameter of high-pressure tubing are selected after calculation. Therefore, when the high-pressure tubing of a cylinder is damaged, the tubing with standard length and diameter should be replaced. In actual use, due to the lack of standard tubing, use other tubing instead of considering whether the length of the tubing and the diameter of the pipe are the same, so that the length of the tubing and the diameter of the pipe are very different, although it can be used in an emergency, but it will lead to changes in the oil supply Angle and the amount of oil supply of the cylinder in advance, resulting in uneven work of the whole machine, so in use must use standard high-pressure tubing.

Five, to regularly check the sealing of the valve coupling.

The injection pump works for a period of time, and by checking the sealing condition of the oil valve, the wear of the plunger and the working condition of the oil pump can be roughly judged, which is conducive to determining the repair and maintenance method. During the inspection, unscrew the high-pressure tubing joint of each cylinder and pump oil with the hand pump of the oil pump, so that there is oil flow out of the tubing joint at the top of the injection pump, which indicates that the oil valve seal is poor (of course, such as the oil valve spring is broken), such as the poor seal phenomenon of multiple cylinders, you should thoroughly debug and maintain the injection pump and replace the couple.

Please call us if you need such products.

Zhuo Meng Shanghai Auto Co., Ltd. is committed to selling MG&MAUXS auto parts welcome to buy.