After the wiper motor is broken how to do.

When the rear wiper motor is broken, the following steps should be taken to deal with it:

Check the fuse: First check whether the fuse of the wiper is intact. If the fuse is blown, it should be replaced immediately to ensure that the motor can work normally.

Check the motor power supply: Use a multimeter to check whether there is voltage in the motor wire plug. If there is no voltage, further check whether the line and direction light combination switch is in good condition.

Check the transmission connecting rod: Open the hood and check whether the transmission connecting rod is dislocated. This is a common cause of the wiper not working properly.

Professional maintenance: If the above steps cannot solve the problem, it is recommended to send the vehicle to a professional auto repair shop for detailed inspection and necessary repair or replacement.

Emergency measures: In a rainy day emergency, if the wiper completely fails, you should stop slowly and turn on the danger warning light. When it is safe to do so, try using a rain repellent spray or wiping the windshield to ensure a clear line of sight, and then look for repair services as soon as possible.

Through the above steps, the problem of the rear wiper motor can be effectively diagnosed and solved to ensure driving safety.

After the wiper motor working principle

The working principle of the rear wiper motor is to drive the connecting rod mechanism by the motor, and convert the rotating motion of the motor into the reciprocating motion of the wiper arm, so as to achieve the wiper action. This process involves several key steps and components that ensure the wiper is able to effectively remove rain or dirt from the windshield, giving the driver a clear view.

First of all, the rear wiper motor is the power source of the entire wiper system, usually using DC permanent magnet motors. This kind of motor receives electrical energy and generates rotating power through internal electromagnetic action. This rotating power is then transmitted through the connecting rod mechanism, converting the rotating motion of the motor into the reciprocating motion of the scraper arm, so that the wiper can work normally.

By controlling the current size of the motor, you can choose a high-speed or low-speed gear, thereby controlling the speed of the motor. The change of speed further affects the motion speed of the scraper arm and realizes the adjustment of the working speed of the wiper. Structurally, the rear end of the wiper motor is usually equipped with a small gear transmission, which can reduce the output speed of the motor to a suitable speed. This device is often referred to as the wiper drive assembly. The output shaft of the assembly is connected with the mechanical device of the wiper end, and the reciprocating swing of the wiper is realized by means of the fork drive and the spring return.

In addition, the modern car wiper is equipped with an electronic intermittent control system, so that the wiper stops scraping in a certain period, so that when driving in light rain or fog, there will be no sticky surface on the glass, thus giving the driver a better view. The intermittent control of the electric wiper can be divided into adjustable and non-adjustable, and the intermittent working mode of the wiper can be realized through complex circuit control.

In general, the working principle of the rear wiper motor is relatively simple, but its structural composition is quite precise, which can provide the driver with a clear vision and ensure driving safety.

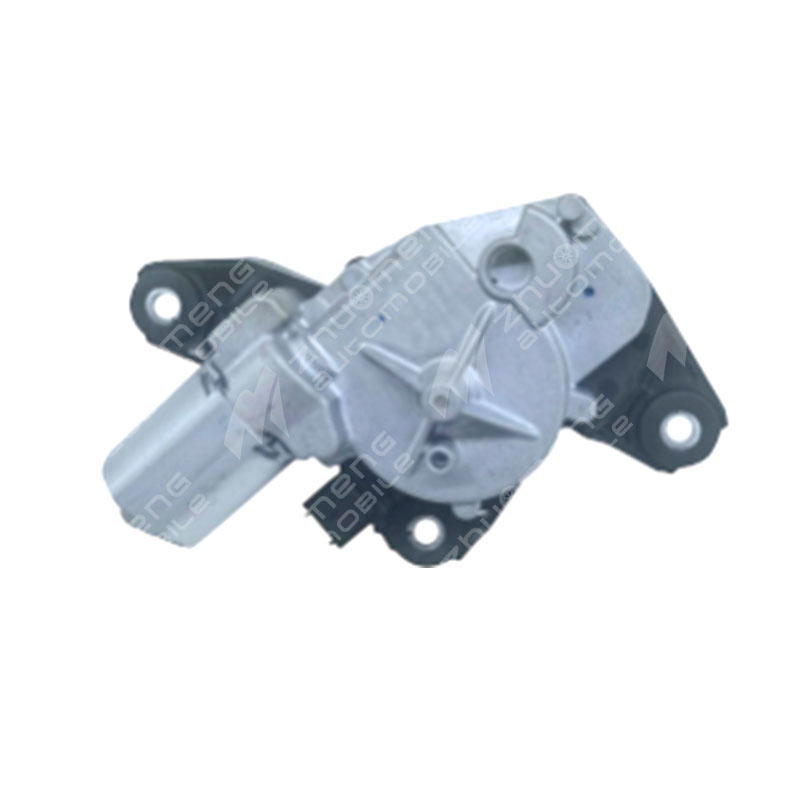

How to remove the rear wiper motor

The steps to remove the rear wiper motor mainly include disconnecting the negative battery, removing the wiper arm, removing the rain collecting plate, removing the plug of the wiper motor assembly, and removing the support.

Disconnect the negative electrode of the battery: This is to ensure safety and avoid an electrical short circuit or accidental start during disassembly.

Remove the wiper arm: Locate the plastic cover under the wiper arm and remove the fixing screw using a screwdriver. A 14mm tool is usually used to complete this step.

Remove the rain collecting plate: After removing the rain scraper arm, you can remove the rain collecting plate on the left side.

Remove the plug of the wiper motor assembly: Pull out the plug of the wiper motor assembly, which is to disconnect the electrical connection of the motor from the vehicle.

Remove the support: Use the appropriate tool to remove the fixing screws of the support, and finally remove the assembly motor.

During the disassembly process, care should be taken not to damage the surrounding parts, especially the wires and plastic parts. In addition, if it is not necessary, it is not recommended to disassemble the installation Angle of the crank arm and the motor, so as not to affect the normal operation of the wiper. When installing a new wiper motor, do so in reverse order, ensuring that all components are properly installed and secured.

These steps work for most models, but the specifics may vary from model to model. Before disassembly and installation, it is recommended to refer to the vehicle's user manual or maintenance manual to ensure the correct and safe operation.

If you want to know more, keep reading the other articles on this site!

Please call us if you need such products.

Zhuo Meng Shanghai Auto Co., Ltd. is committed to selling MG&MAUXS auto parts welcome to buy.