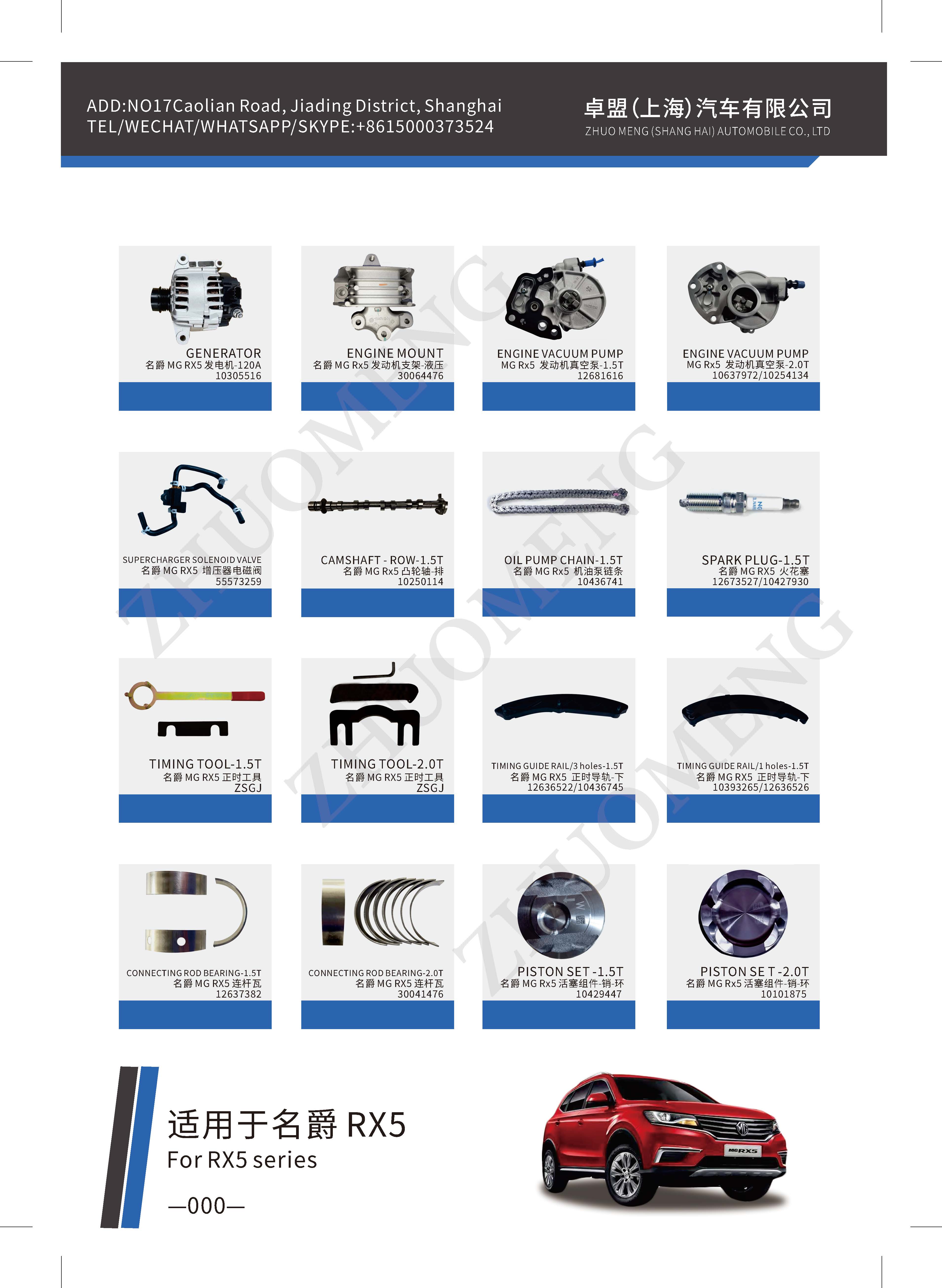

A component used to increase the oil pressure and ensure a certain amount of oil, forcing oil to each friction surface. Gear type and rotor type oil pump are widely used in internal combustion engines. Gear type oil pump has the advantages of simple structure, convenient processing, reliable operation, long service life, high pump oil pressure, widely used rotor pump rotor shape is complex, multi-purpose powder metallurgy pressing. This pump has the same advantages of gear pump, but compact structure, small size

Smooth operation, low noise. Cycloid rotor pump internal and external rotor teeth only one tooth, when they do relative motion, the sliding speed of the tooth surface is small, the meshing point is constantly moving along the internal and external rotor tooth profile, therefore, the two rotor tooth surface wear each other small. Because the envelope Angle of the oil suction chamber and the oil discharge chamber is large, close to 145°, the oil suction and oil discharge time are sufficient, therefore, the oil flow is relatively stable, the movement is relatively stable, and the noise is significantly lower than the gear pump