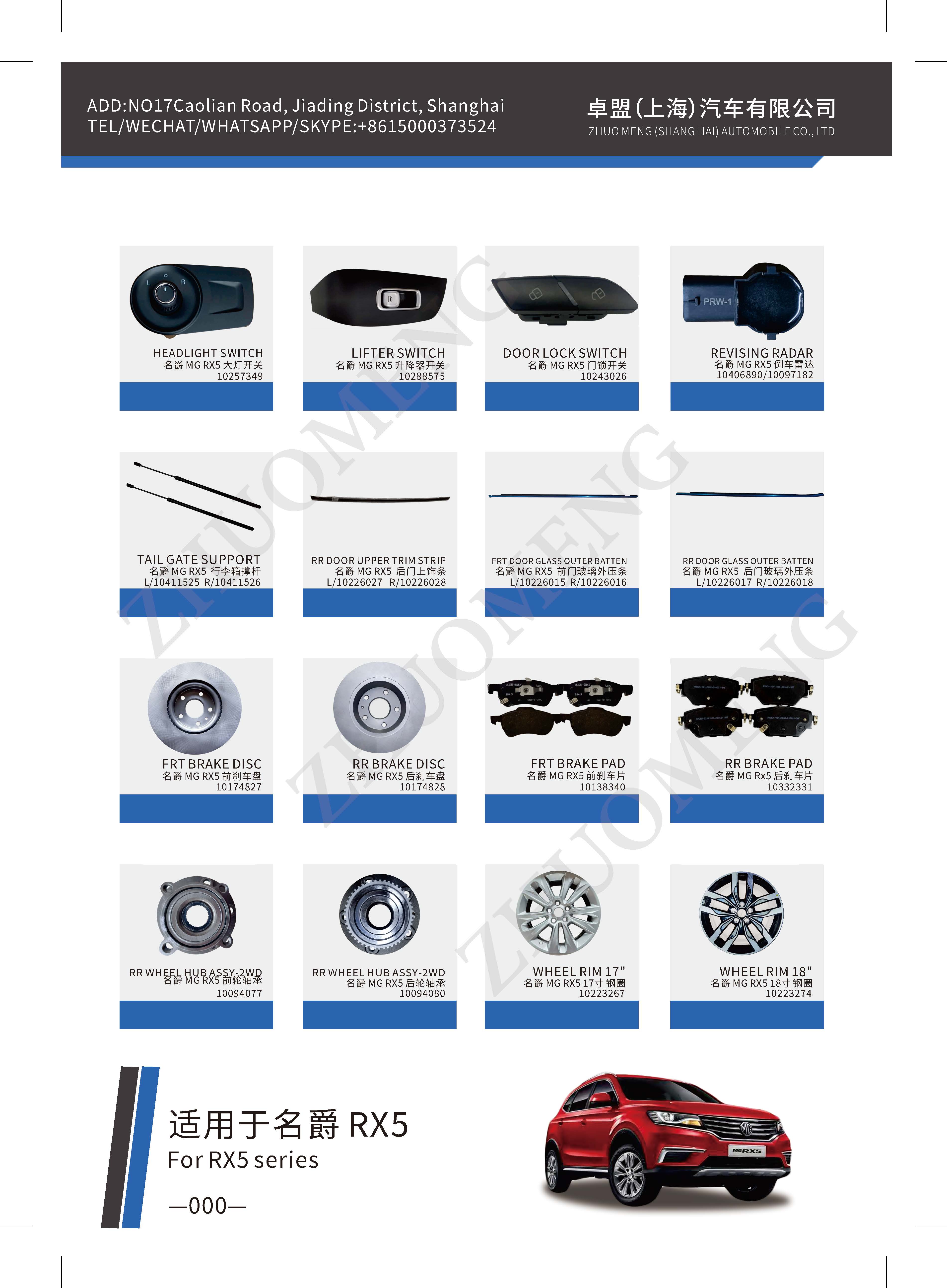

Brake pads are also called brake pads. In the car brake system, the brake pad is the most critical safety parts, all the brake effect is good or bad is the brake pad plays a decisive role, so a good brake pad is the protection of people and cars.

Brake pads are generally composed of steel plate, adhesive heat insulation layer and friction block. Steel plate should be coated to prevent rust. In the coating process, SMT-4 furnace temperature tracker is used to detect the temperature distribution in the coating process to ensure the quality. The heat insulation layer is composed of non-heat transfer material, the purpose of heat insulation. The friction block is composed of friction materials and adhesives. When braking, it is squeezed on the brake disc or brake drum to produce friction, so as to achieve the purpose of slowing down the vehicle. As a result of friction, the friction block will gradually be worn, generally speaking, the lower the cost of brake pads wear faster.

Automotive brake pads are divided into types: - brake pads for disc brakes - brake shoes for drum brakes - brake pads for large trucks

Brake pads are mainly divided into the following categories: metal brake skin and carbon ceramic brake skin, metal brake skin is divided into less metal brake skin and semi-metal brake skin, ceramic brake skin is classified as less metal, carbon ceramic brake skin is used with carbon ceramic brake disc.