Professional Design Mg 5 Parts Catalogue - 50015033 350 Rear Brake Disc Guard-R – Zhuomeng

Professional Design Mg 5 Parts Catalogue - 50015033 350 Rear Brake Disc Guard-R – Zhuomeng Detail:

Products information

| Products Name | Rear Brake Disc Guard |

| Products Application | Saic Mg- 350 |

| Products Oem No | 50015033 |

| Org Of Place | Made In China |

| Brand | Cssot / Rmoem / Org / Copy |

| Lead Time | Stock, If Less 20 Pcs, Normal One Month |

| Payment | Tt Deposit |

| Company Brand | Cssot |

| Application System | Chassis System |

Product knowledge

Measures to prevent brake disc shrinkage and looseness: the molten iron is introduced into the sprue evenly to reduce local overheating of the disc and prevent the formation of artificial hot spots. According to the viewpoint of balanced solidification of iron castings, the more thin-walled small parts, the greater the shrinkage value, and the more emphasis on shrinkage. Feeding mode can be gating system feeding or riser feeding. When the feeding scheme of gating system is adopted, the sprue head can be appropriately increased, such as increasing the height of upper box, adding gate ring, etc; The cross runner is the main unit of skimming and floating air. When it is used for shrinkage supplement, its section size can be increased appropriately; The internal sprue shall be short, thin and wide. The internal sprue is short (the transverse sprue is close to the casting). Due to the thermal influence of the casting and the transverse sprue and the flow effect of molten iron filling and feeding, the internal sprue will not be solidified and closed in advance, and it will remain unblocked for a long time. Thin (generally) can prevent the formation of contact hot joints at the inlet of the internal sprue. The width is to ensure sufficient overflow area. Once the casting enters the balanced solidification stage of graphitization expansion and contraction, the molten iron in the ingate will stop flowing and will solidify and stop in time to improve the utilization rate of graphitization self feeding, which is the adaptive adjustment effect of short, thin and wide ingate (riser neck) on feeding. For some castings with serious shrinkage, a riser can be set for feeding. The riser is best set at the beginning of the inner sprue, or a riser can be set at the middle core to feed the disc on one side of the inner sprue. For small thin-walled parts, secondary inoculation measures can be adopted, that is, inoculant can be added into the small package for instantaneous inoculation to improve the inoculation effect and promote the nucleation and growth of graphite. It can be added at the bottom of the package and washed into molten iron.

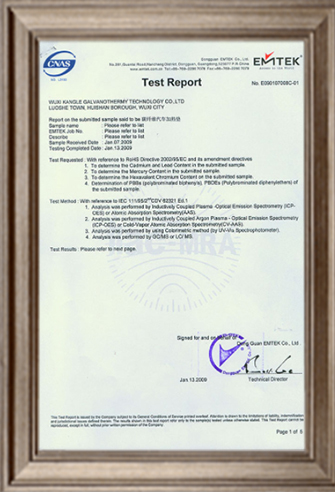

certificate

exhibition

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Professional Design Mg 5 Parts Catalogue - 50015033 350 Rear Brake Disc Guard-R – Zhuomeng , The product will supply to all over the world, such as: Canada, India, Guinea, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!