Ordinary Discount Mg 350 Car Accessories - 50015032 350 Rear Brake Disc Guard – Zhuomeng

Ordinary Discount Mg 350 Car Accessories - 50015032 350 Rear Brake Disc Guard – Zhuomeng Detail:

Products information

| Products Name | Rear Brake Disc Guard |

| Products Application | Saic Mg 350, ZS |

| Products Oem No | 50015032, 50015013 |

| Org Of Place | Made In China |

| Brand | Cssot / Rmoem / Org / Copy |

| Lead Time | Stock, If Less 20 Pcs, Normal One Month |

| Payment | Tt Deposit |

| Company Brand | Cssot |

| Application System | Chassis System |

50015032 350 REAR BRAKE DISC GUARD-L

Common defects and how to prevent them?

Common defects in brake disc production: air hole, shrinkage porosity, sand hole, etc; The medium and type graphite in the metallographic structure exceed the standard, or the carbide quantity standard; Too high Brinell hardness leads to difficult processing or uneven hardness; The graphite structure is coarse, the mechanical properties are not up to standard, the roughness is poor after processing, and the obvious porosity on the casting surface also occurs from time to time.

1. Formation and prevention of air holes: air holes are one of the most common defects of brake disc castings. Brake disc parts are small and thin, cooling and solidification speed is fast, and there is little possibility of precipitation air holes and reactive air holes. The fat oil binder sand core has a large gas generation. If the mold moisture content is high, these two factors often lead to invasive pores in the casting. It is found that if the moisture content of molding sand exceeds, the porosity scrap rate increases significantly; In some thin sand core castings, choking (choking pores) and surface pores (shelling) often appear. When the resin coated sand hot core box method is used, the pores are particularly serious due to the large gas generation; Generally, the brake disc with thick sand core rarely has air hole defects;

2. Formation of air hole: the gas generated by the disc sand core of brake disc casting at high temperature shall flow outward or inward horizontally through the core sand gap under normal conditions. The disc sand core becomes thinner, the gas path becomes narrow and the flow resistance increases. In one case, when the molten iron quickly submerges the disc sand core, a large amount of gas will burst out; Or high-temperature molten iron contacts with high water content sand mass (uneven sand mixing) at some place, causing gas explosion, choking fire and forming choking pores; In another case, the formed high-pressure gas invades the molten iron and floats up and escapes. When the mold cannot discharge it in time, the gas will spread into a gas layer between the molten iron and the lower surface of the upper mold, occupying part of the space on the upper surface of the disc. If the molten iron is solidifying, or the viscosity is large and loses fluidity, the space occupied by the gas cannot be refilled, Will leave surface pores. Generally, if the gas generated by the core cannot float up and escape through the molten iron in time, it will stay on the upper surface of the disc, sometimes exposed as a single pore, sometimes exposed after shot blasting to remove the oxide scale, and sometimes found after machining, which will cause a waste of processing hours. When the brake disc core is thick, it takes a long time for molten iron to rise through the disc core and submerge the disc core. Before submerging, the gas generated by the core has more time to flow freely to the upper surface of the core through the sand gap, and the resistance to flow outward or inward in the horizontal direction is also small. Therefore, surface pore defects are rarely formed, but individual isolated pores may also occur. That is to say, there is a critical size to form choking pores or surface pores between the thickness and thickness of the sand core. Once the thickness of the sand core is less than this critical size, there will be a serious tendency of pores. This critical dimension increases with the increase of the radial dimension of the brake disc and with the thinning of the disc core. Temperature is an important factor affecting porosity. The molten iron enters the mold cavity from the inner sprue, bypasses the middle core when filling the disc, and meets opposite the inner sprue. Due to the relatively long process, the temperature decreases more, and the viscosity increases accordingly, the effective time for the bubbles to float up and discharge is short, and the molten iron will solidify before the gas is completely discharged, so pores are easy to occur. Therefore, the effective time of bubble floating and discharging can be prolonged by increasing the molten iron temperature at the disc opposite the inner sprue.

50015013 350 FRONT BRAKE DISC GUARD-R

Large means that the friction force generated in the whole braking process is large, which means that the braking effect is better than that of the later cars. The engines of some cars are installed on the front of the car, which leads to a large history of weight cost of the head. The greater the pressure, the greater the inertia. Because of the greater friction force during braking, the brake disc will naturally be larger, and the mass transfer will occur when the car is braking, Although it seems that the body is relatively stable on the surface, in fact, under the action of inertia, the center of gravity of the car shifts forward at this time, and the pressure of the front wheel increases sharply. Naturally, we need better brake discs and brake discs, which is also for our driving safety.

There is a lot of knowledge about the front brake disc, because whenever you need to step on the car on the way, due to the influence of inertia, the front part of the car will go up to the exit branch of the car, so the strength of the front tire will increase. At this time, the front blood tire needs more braking force than the history behind, so that the car can be used to brake the disc and the car quickly and smoothly, Because the front part of the car body is pressed to the ground, the rear wheel will lift up. At this time, the contact force between the rear wheel and the ground, that is, the grip is not as large as the front wheel, so there is no need for such a large braking force.

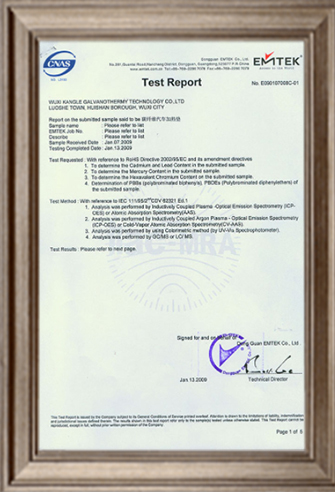

certificate

exhibition

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Ordinary Discount Mg 350 Car Accessories - 50015032 350 Rear Brake Disc Guard – Zhuomeng , The product will supply to all over the world, such as: Czech, Canada, Jamaica, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!