OEM/ODM China Mg Zx Spare Parts Factory - MAXUS AUTO PARTS SUPPLIER SAIC MAXUS V80 connecting rod C00014584/8203 – Zhuomeng

OEM/ODM China Mg Zx Spare Parts Factory - MAXUS AUTO PARTS SUPPLIER SAIC MAXUS V80 connecting rod C00014584/8203 – Zhuomeng Detail:

Products information

| Products name | connecting rod |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C00014584/8203 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | POWER system |

Products knowledge

Connect the piston and the crankshaft, and transmit the force on the piston to the crankshaft, converting the reciprocating motion of the piston into the rotational motion of the crankshaft.

The connecting rod group is composed of connecting rod body, connecting rod big end cap, connecting rod small end bushing, connecting rod big end bearing bush and connecting rod bolts (or screws). The connecting rod group is subjected to the gas force from the piston pin, its own swing and the reciprocating inertial force of the piston group. The magnitude and direction of these forces change periodically. Therefore, the connecting rod is subjected to alternating loads such as compression and tension. The connecting rod must have sufficient fatigue strength and structural rigidity. Insufficient fatigue strength will often cause the connecting rod body or connecting rod bolt to break, resulting in a major accident of damage to the whole machine. If the stiffness is insufficient, it will cause bending deformation of the rod body and out-of-round deformation of the big end of the connecting rod, resulting in eccentric wear of the piston, cylinder, bearing and crank pin.

Structure and composition

The connecting rod body consists of three parts, the part connected with the piston pin is called the small end of the connecting rod; the part connected with the crankshaft is called the big end of the connecting rod, and the part connecting the small end and the big end is called the connecting rod body.

The small end of the connecting rod is mostly a thin-walled annular structure. In order to reduce the wear between the connecting rod and the piston pin, a thin-walled bronze bushing is pressed into the small end hole. Drill or mill grooves in the small head and bushing to allow splashing oil to enter the mating surfaces of the lubricating bushing and piston pin.

The connecting rod shaft is a long rod, and it is also subjected to large forces during work. In order to prevent it from bending and deforming, the rod body must have sufficient rigidity. For this reason, most of the connecting rod shafts of vehicle engines use I-shaped sections, which can minimize the mass with sufficient rigidity and strength, and H-shaped sections are used in high-strengthened engines. Some engines use the small end of the connecting rod to spray oil to cool the piston, and a through hole must be drilled in the longitudinal direction of the rod body. In order to avoid stress concentration, the connection between the connecting rod body and the small end and the big end adopts a smooth transition of large arc.

In order to reduce the vibration of the engine, the quality difference of each cylinder connecting rod must be limited to the minimum range. When assembling the engine in the factory, it is generally grouped according to the mass of the large and small ends of the connecting rod in grams. Group connecting rod.

On the V-type engine, the corresponding cylinders of the left and right rows share a crank pin, and the connecting rods have three types: parallel connecting rods, fork connecting rods and main and auxiliary connecting rods.

Main form of damage

The main damage forms of connecting rods are fatigue fracture and excessive deformation. Usually fatigue fractures are located in three high stress areas on the connecting rod. The working conditions of the connecting rod require the connecting rod to have high strength and fatigue resistance; it also requires sufficient rigidity and toughness. In the traditional connecting rod processing technology, the materials generally use quenched and tempered steel such as 45 steel, 40Cr or 40MnB, which have higher hardness. Therefore, the new connecting rod materials produced by German automobile companies such as C70S6 high carbon microalloy non-quenched and tempered steel, SPLITASCO series Forged steel, FRACTIM forged steel and S53CV-FS forged steel, etc. (the above are all German din standards). Although alloy steel has high strength, it is very sensitive to stress concentration. Therefore, strict requirements are required in the shape of the connecting rod, excessive fillet, etc., and attention should be paid to the surface processing quality to improve the fatigue strength, otherwise the application of high-strength alloy steel will not achieve the desired effect.

OUR EXHIBITION

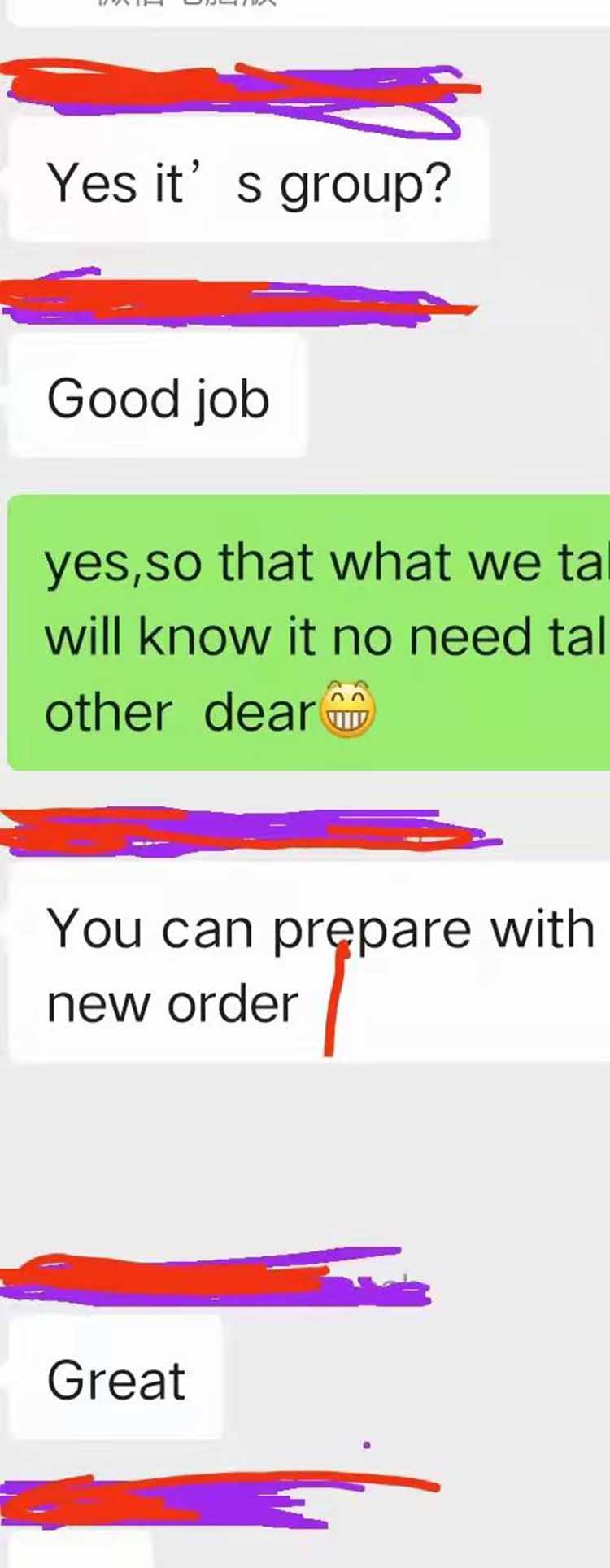

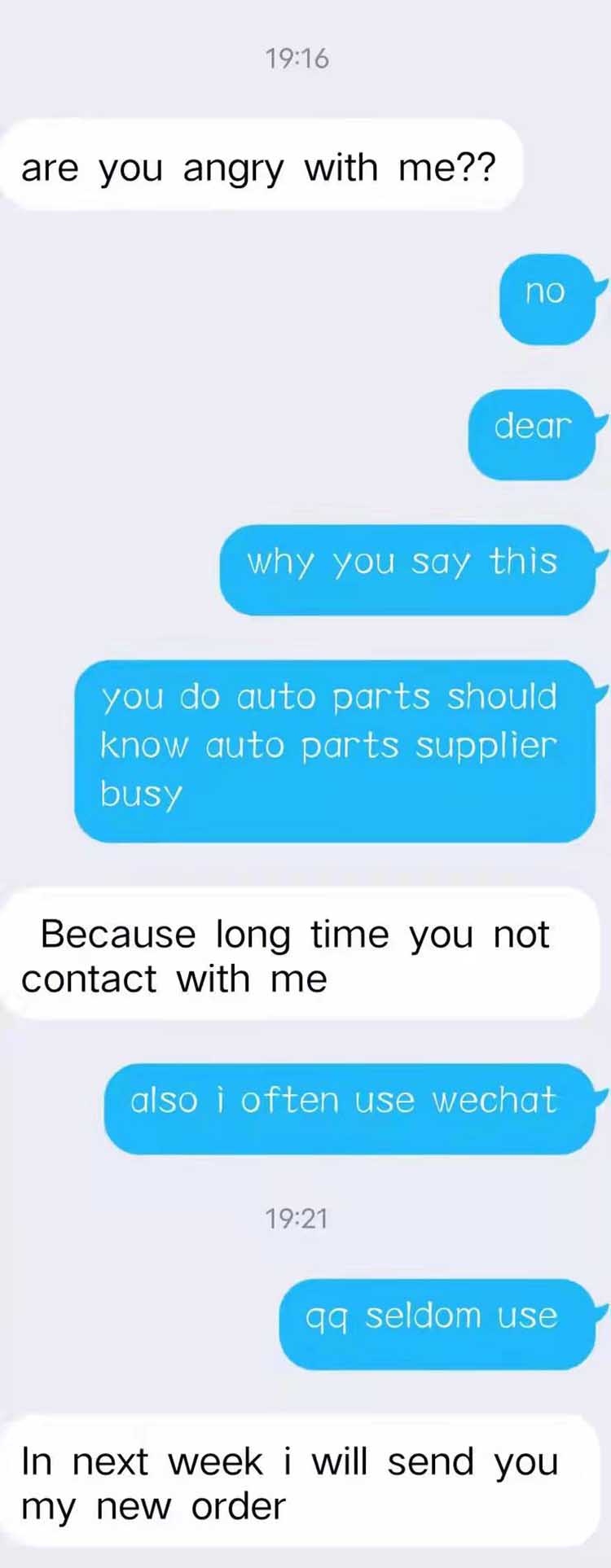

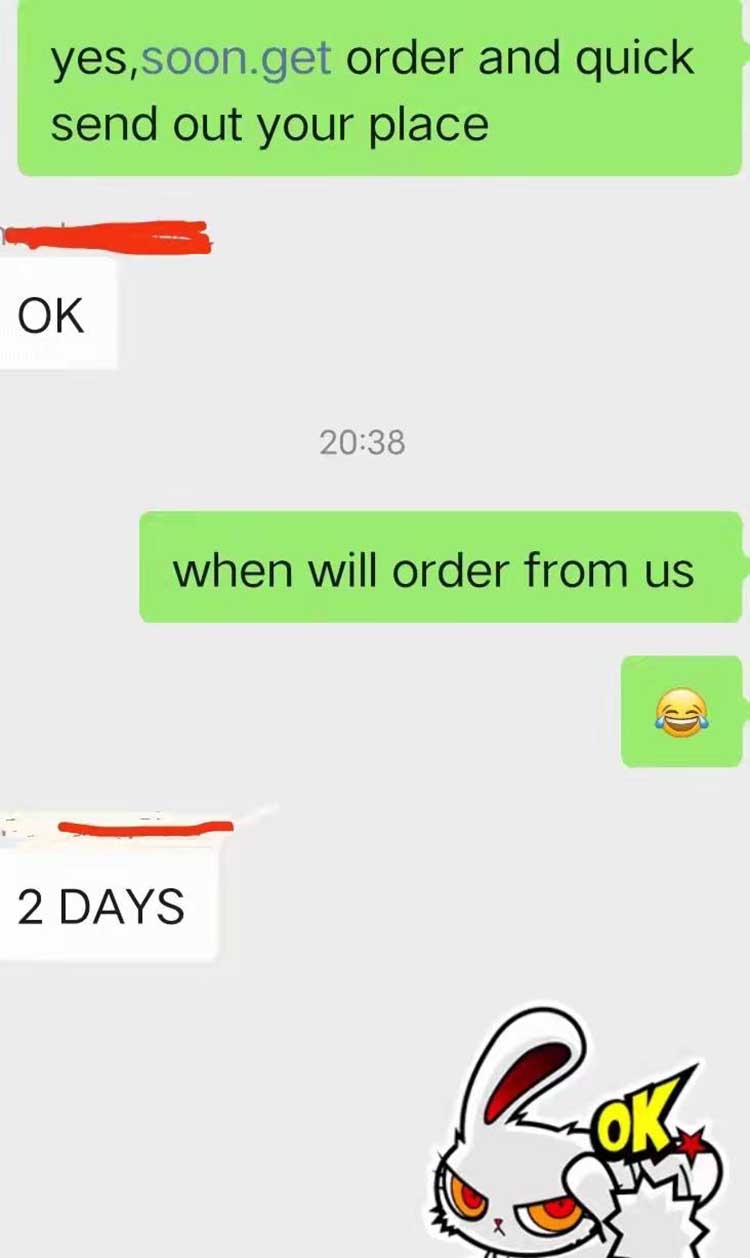

Good Feetback

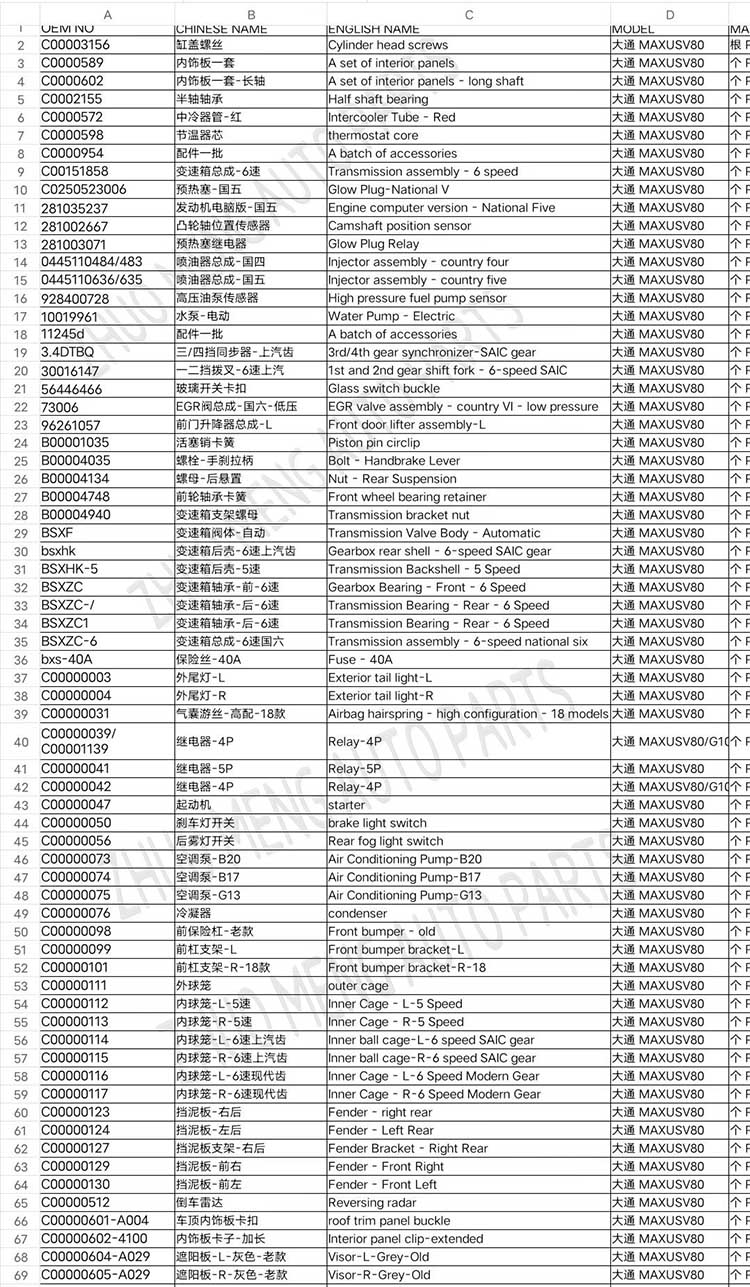

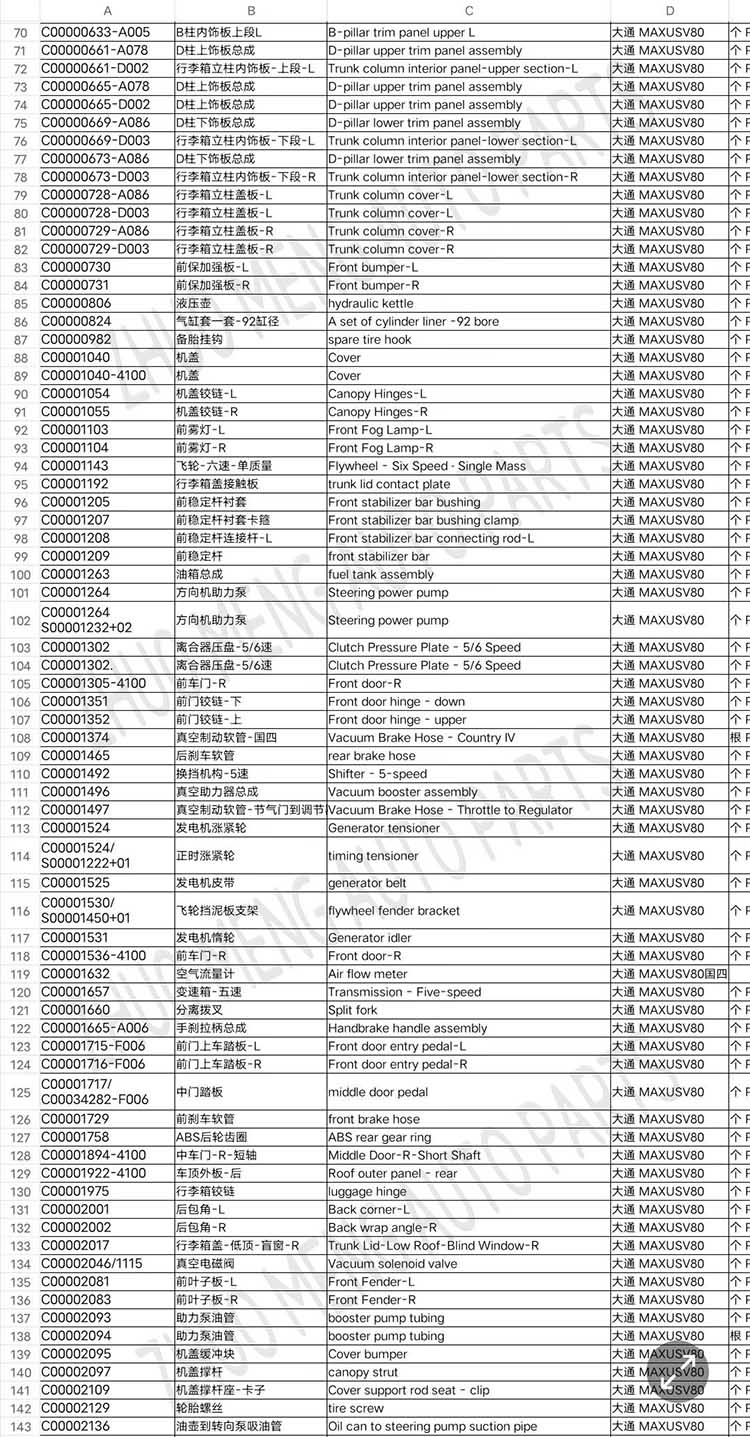

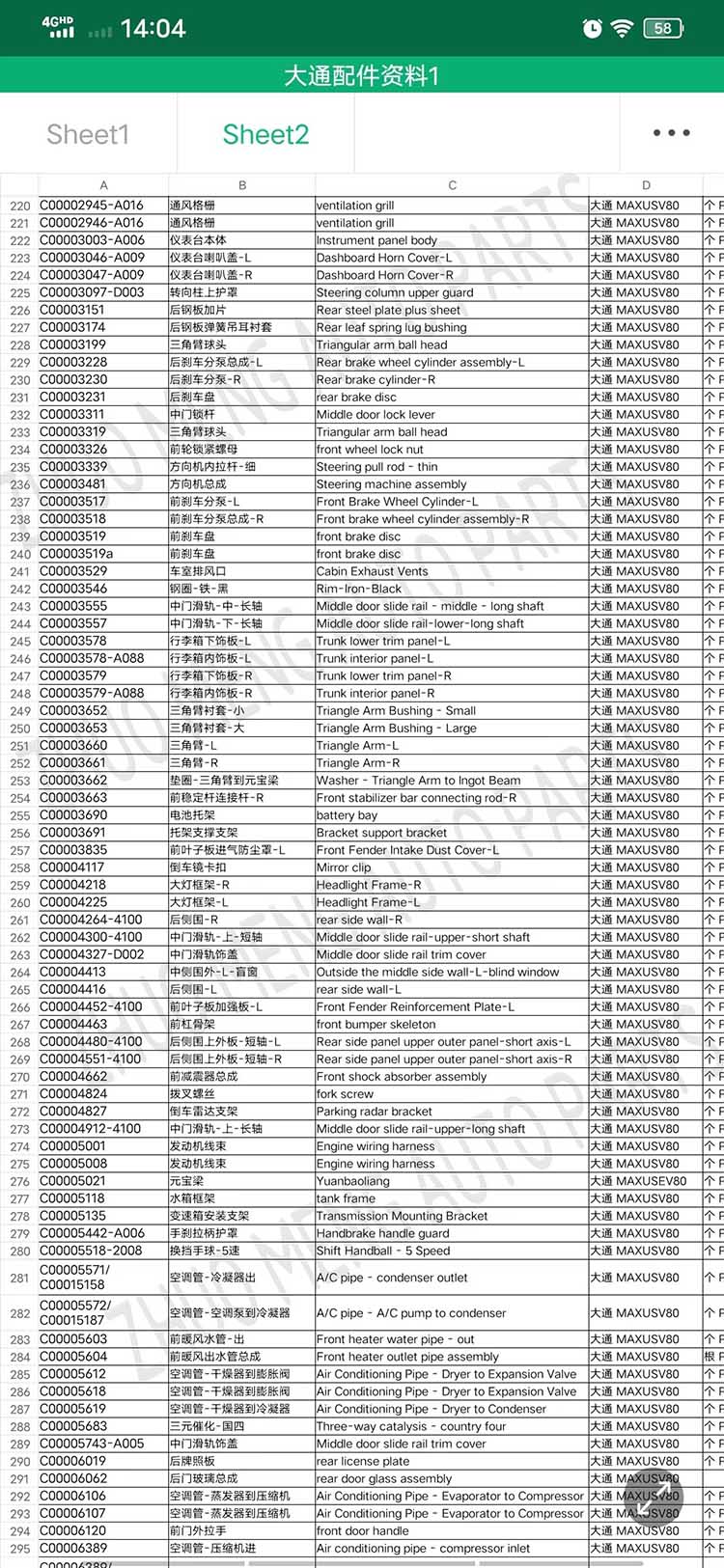

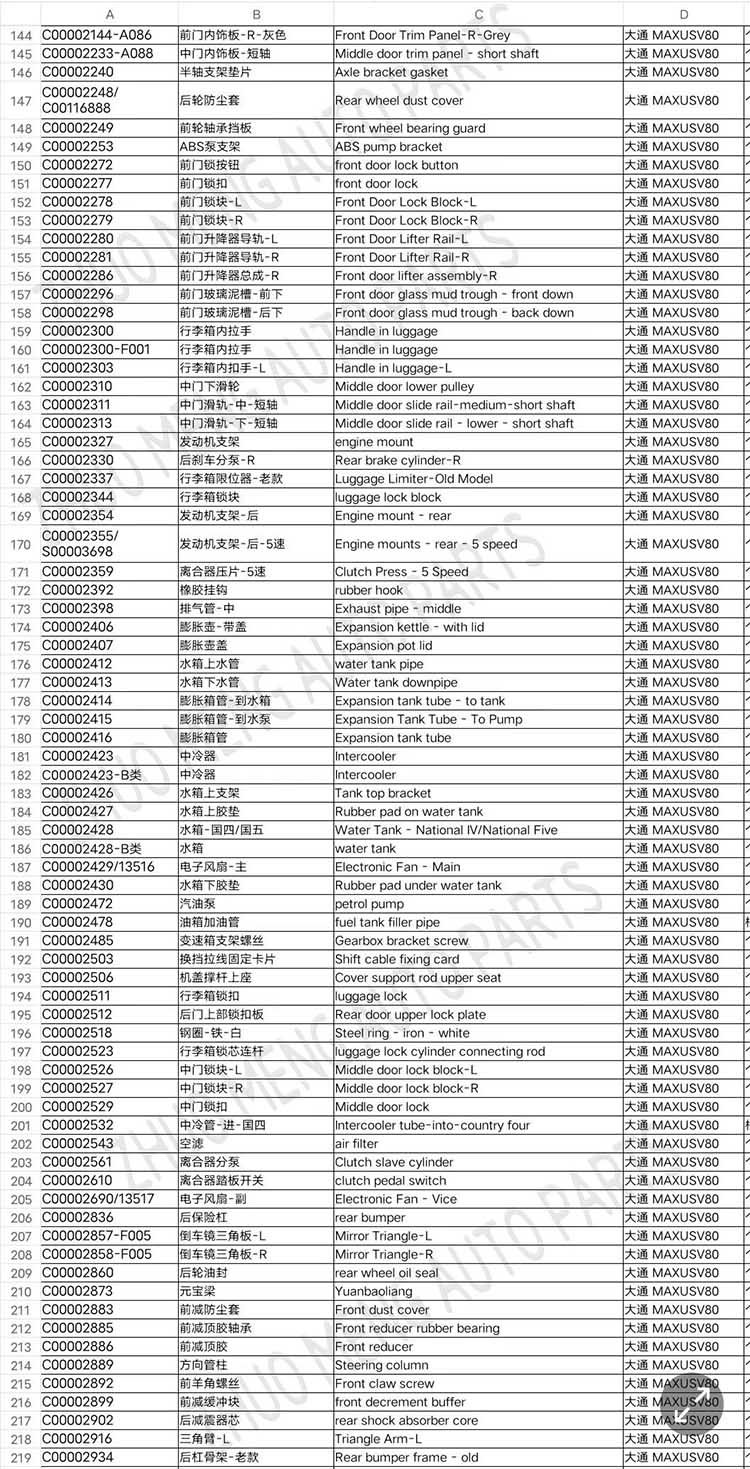

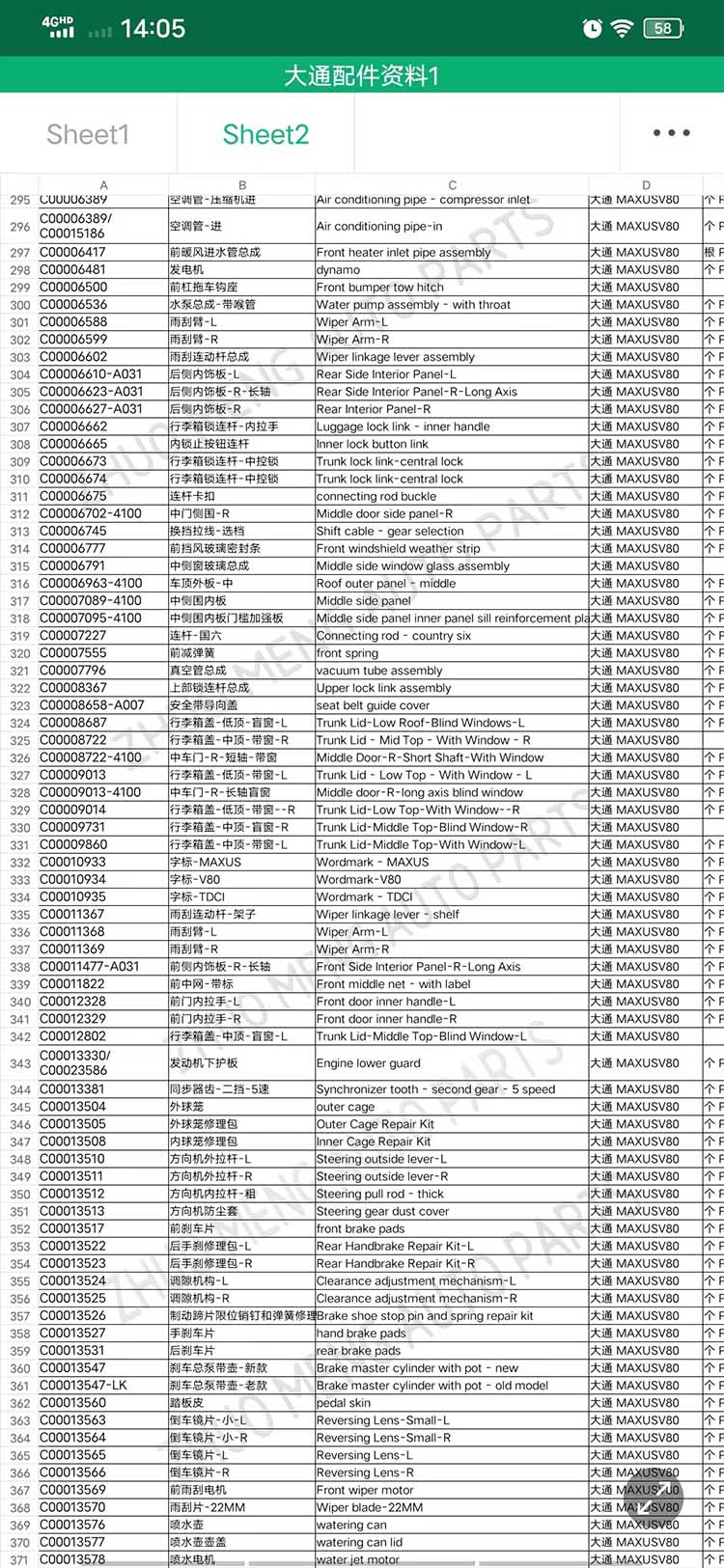

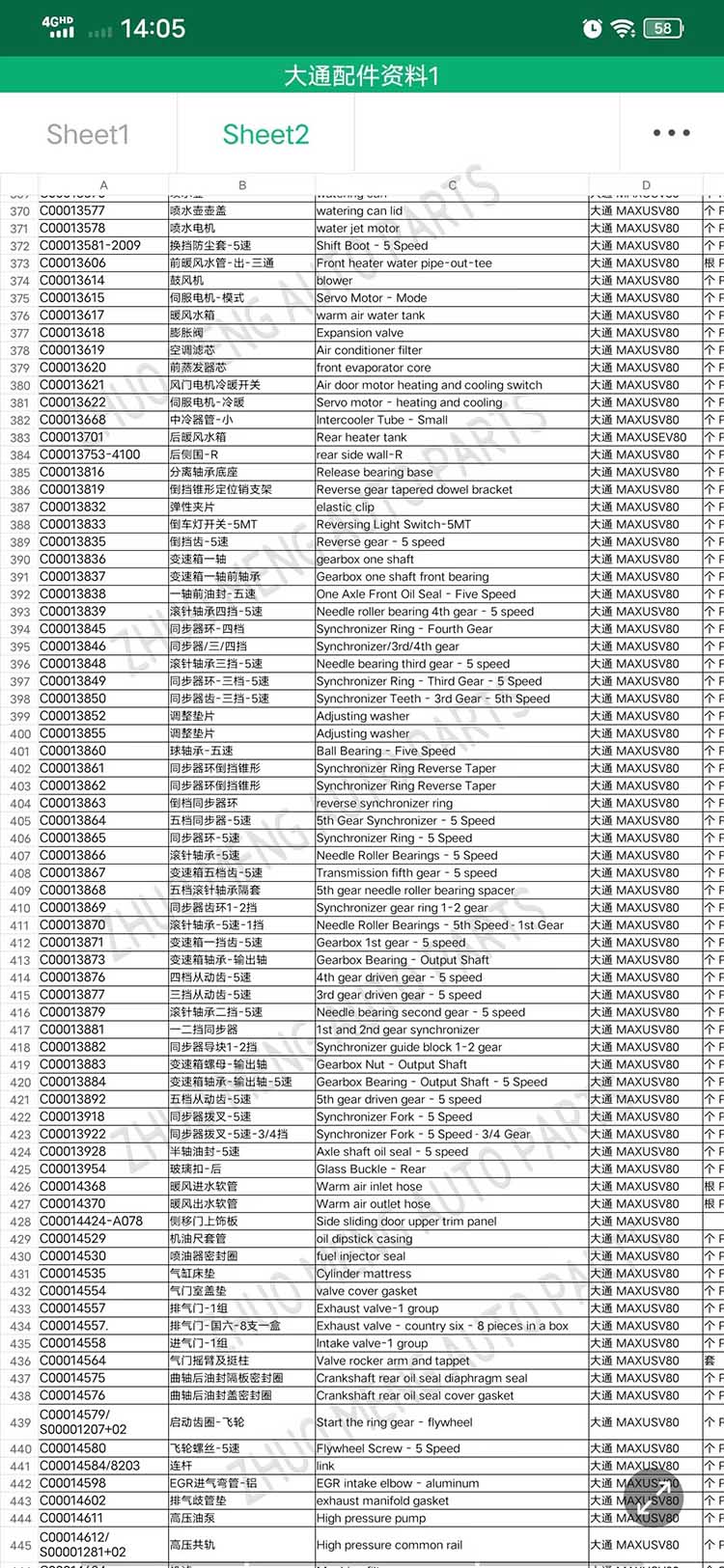

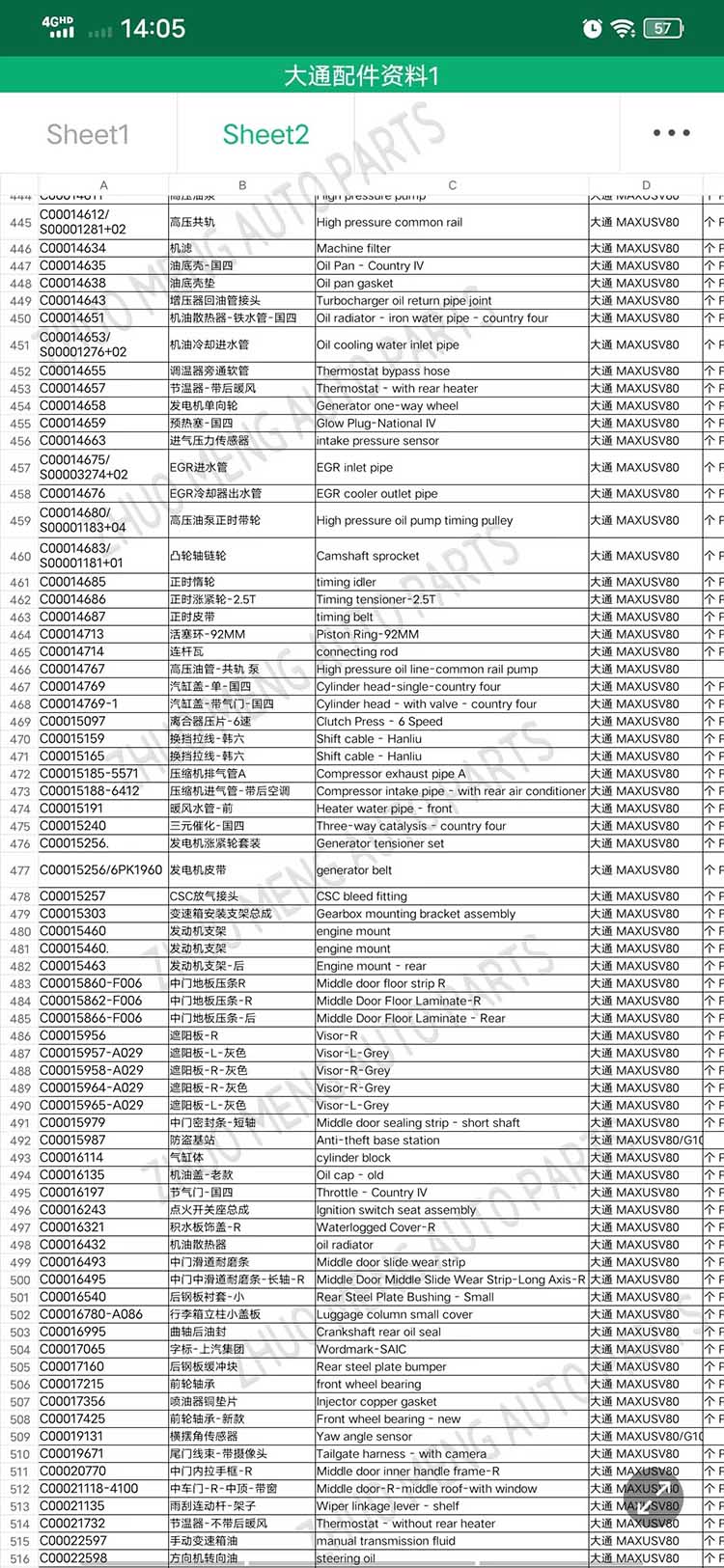

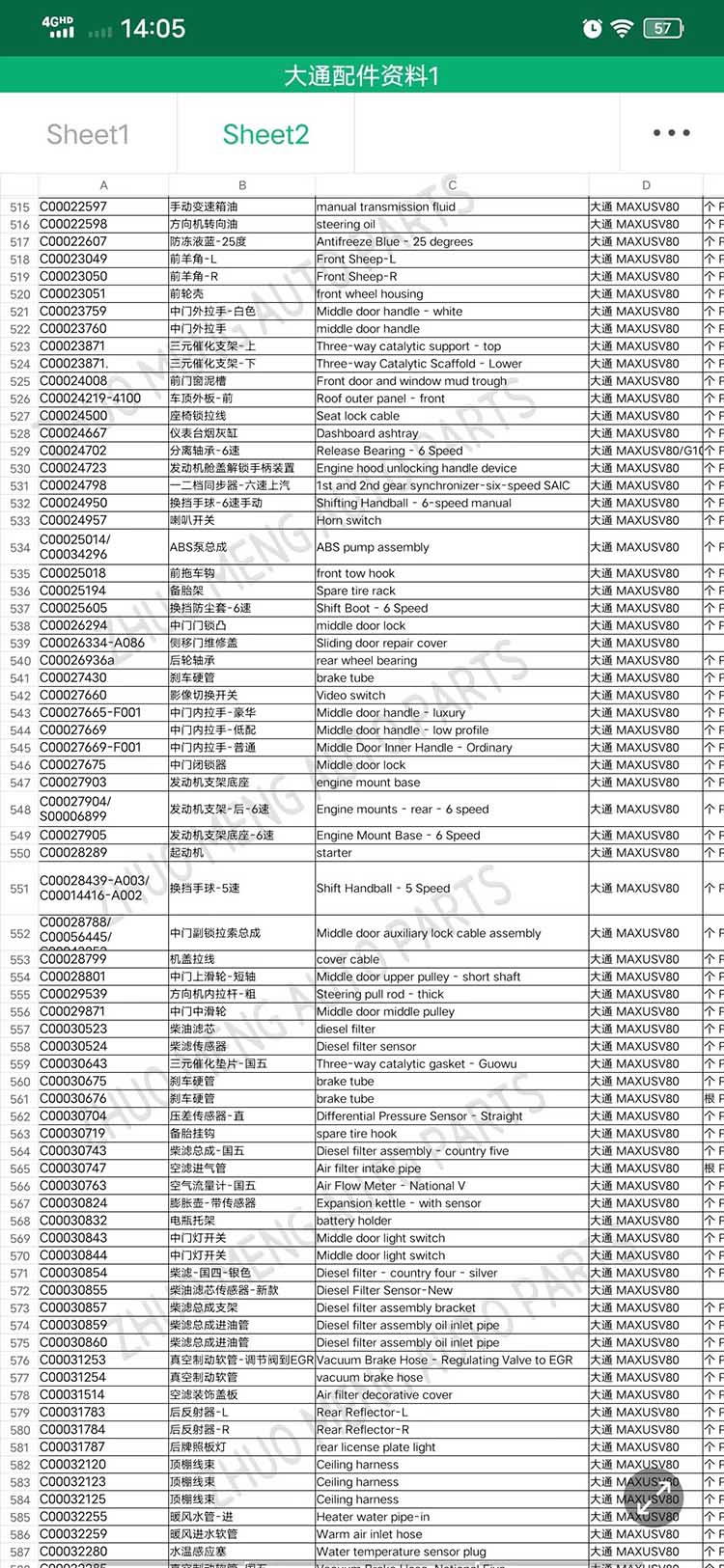

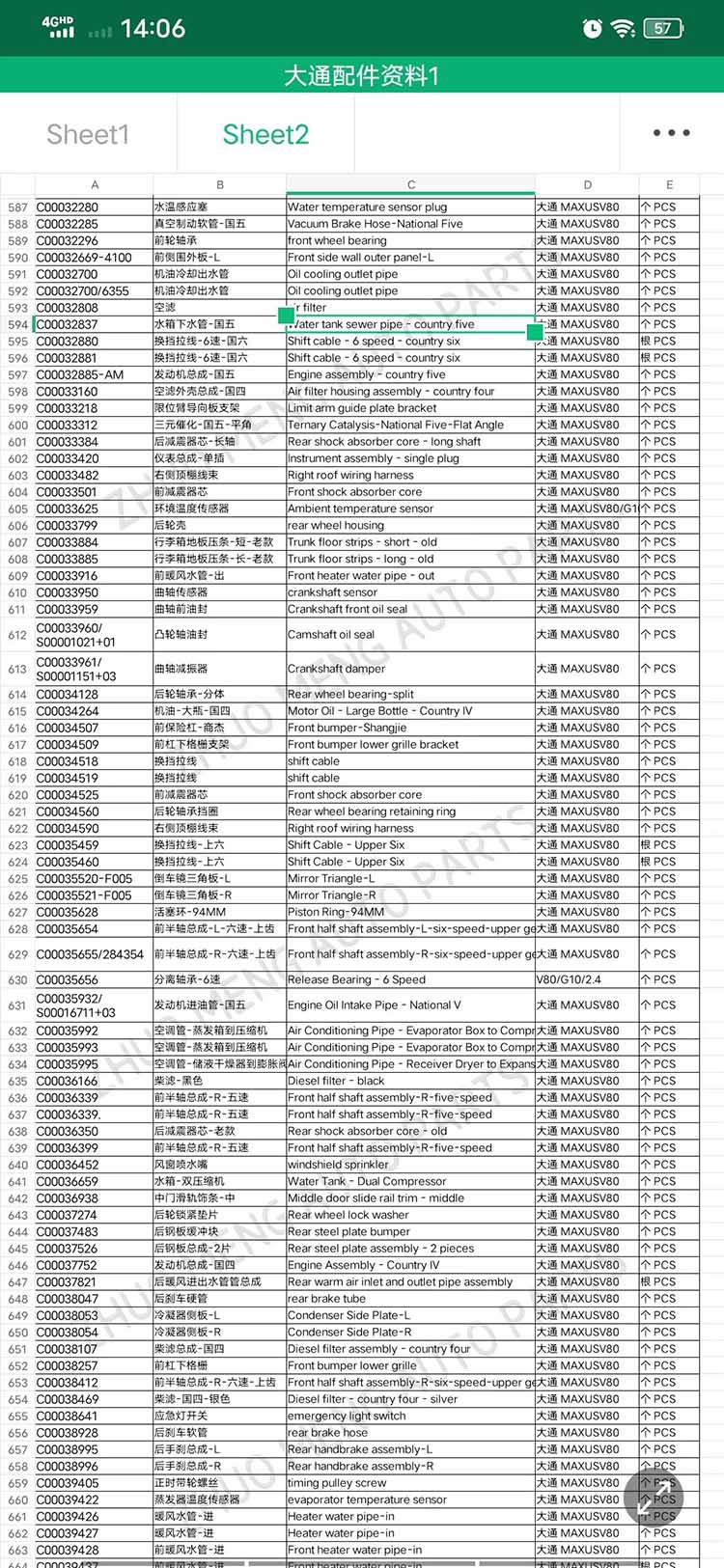

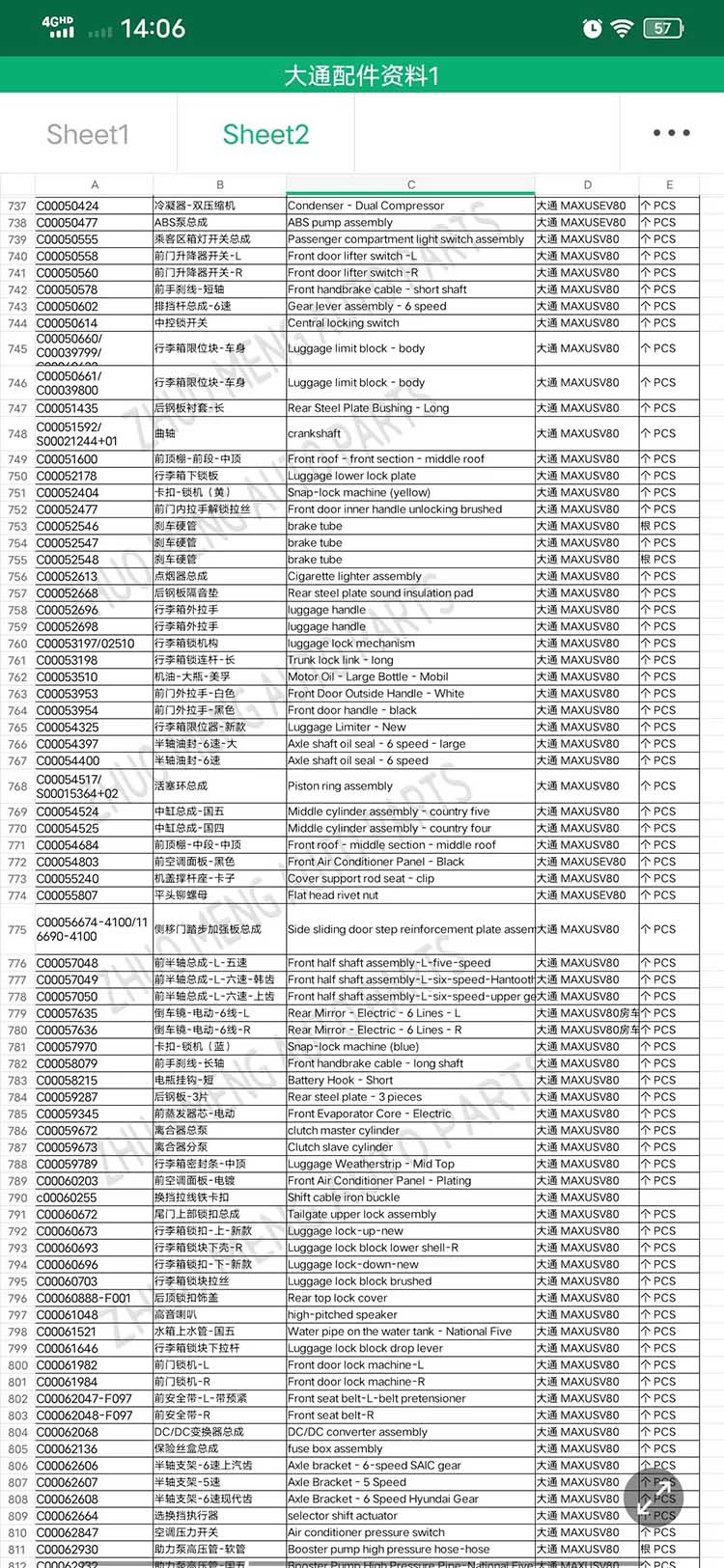

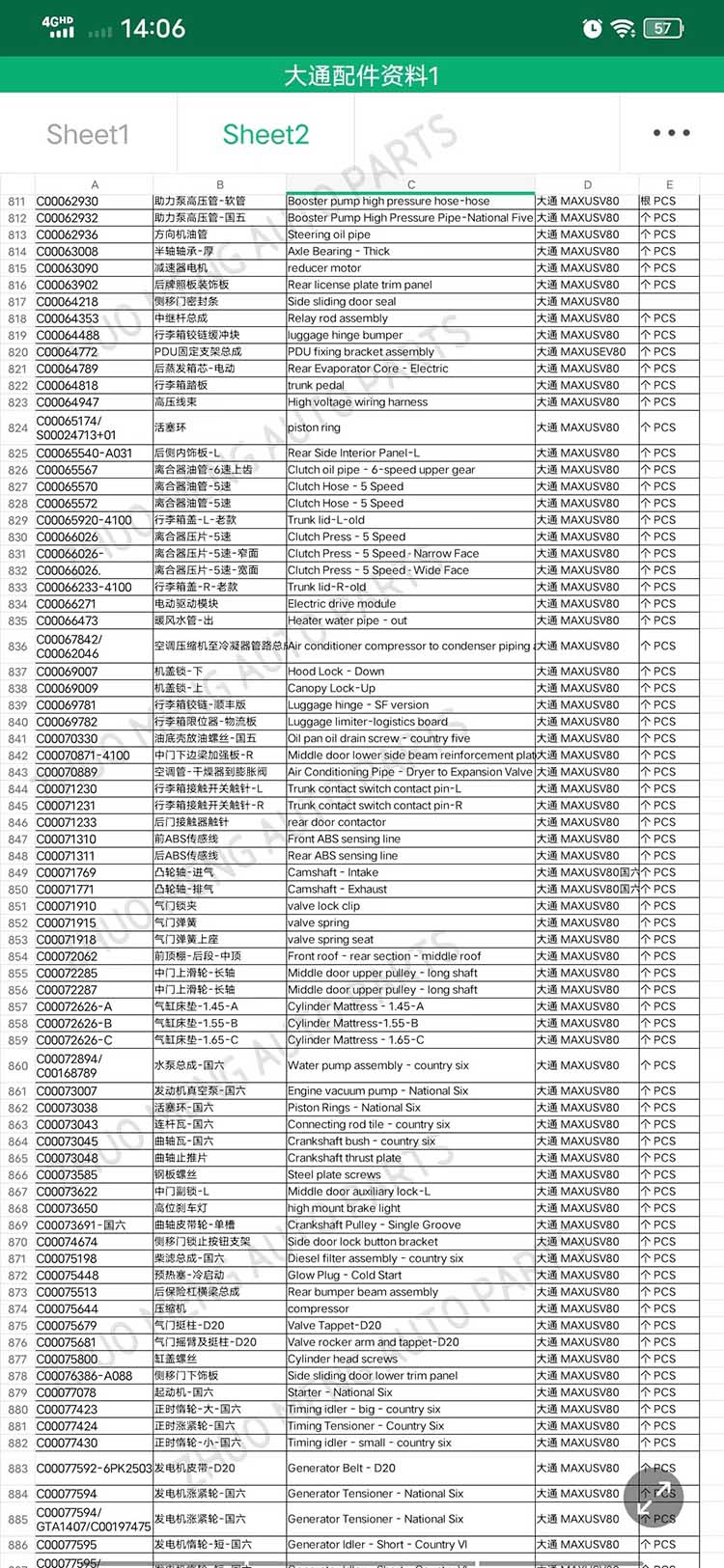

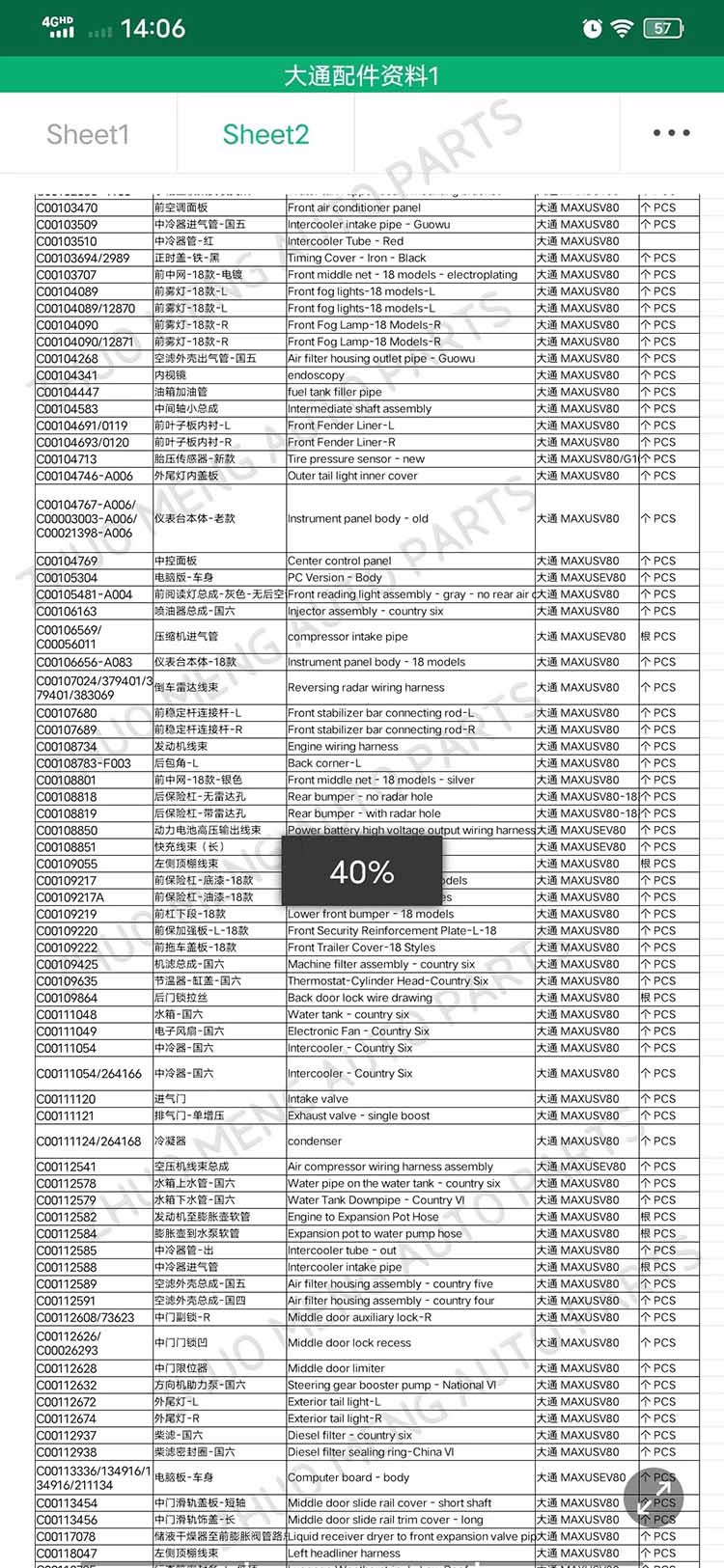

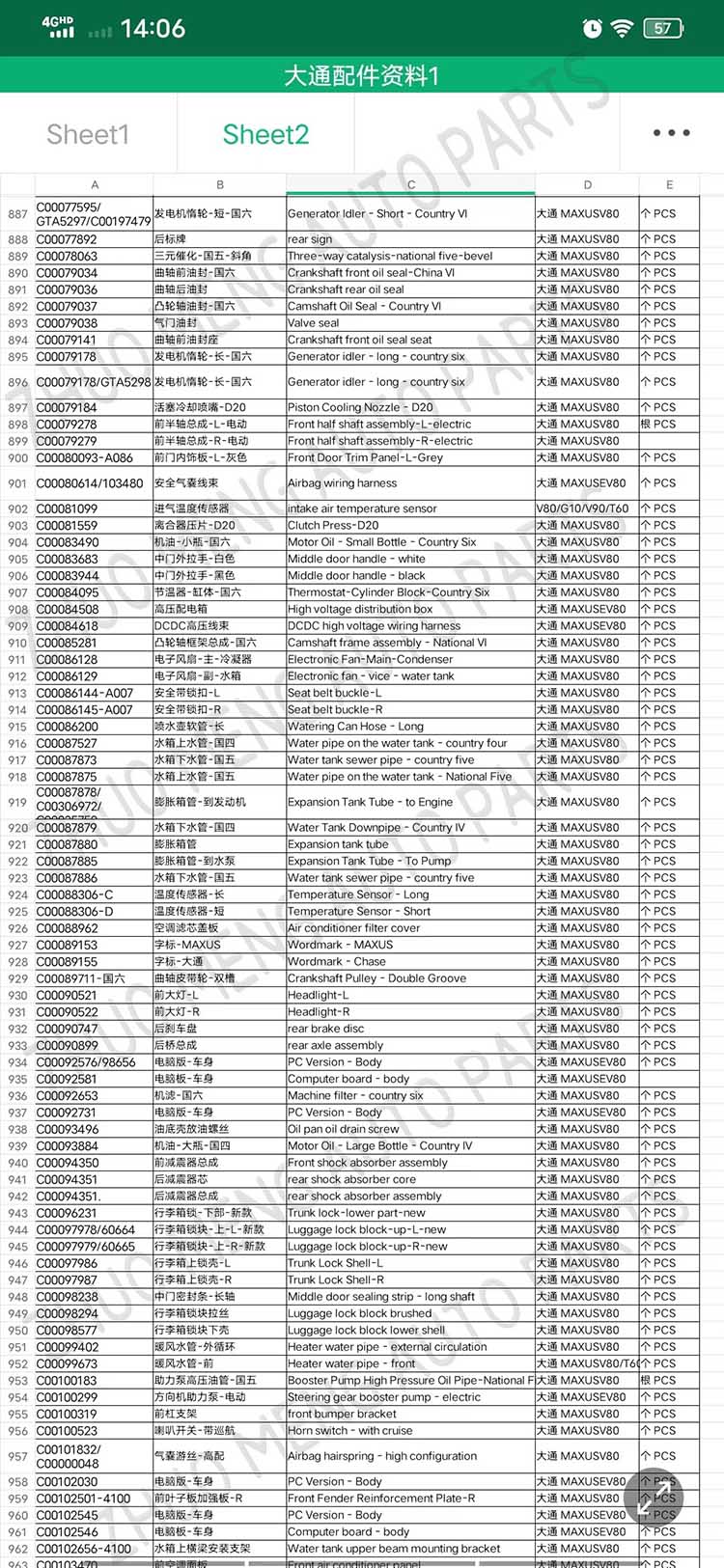

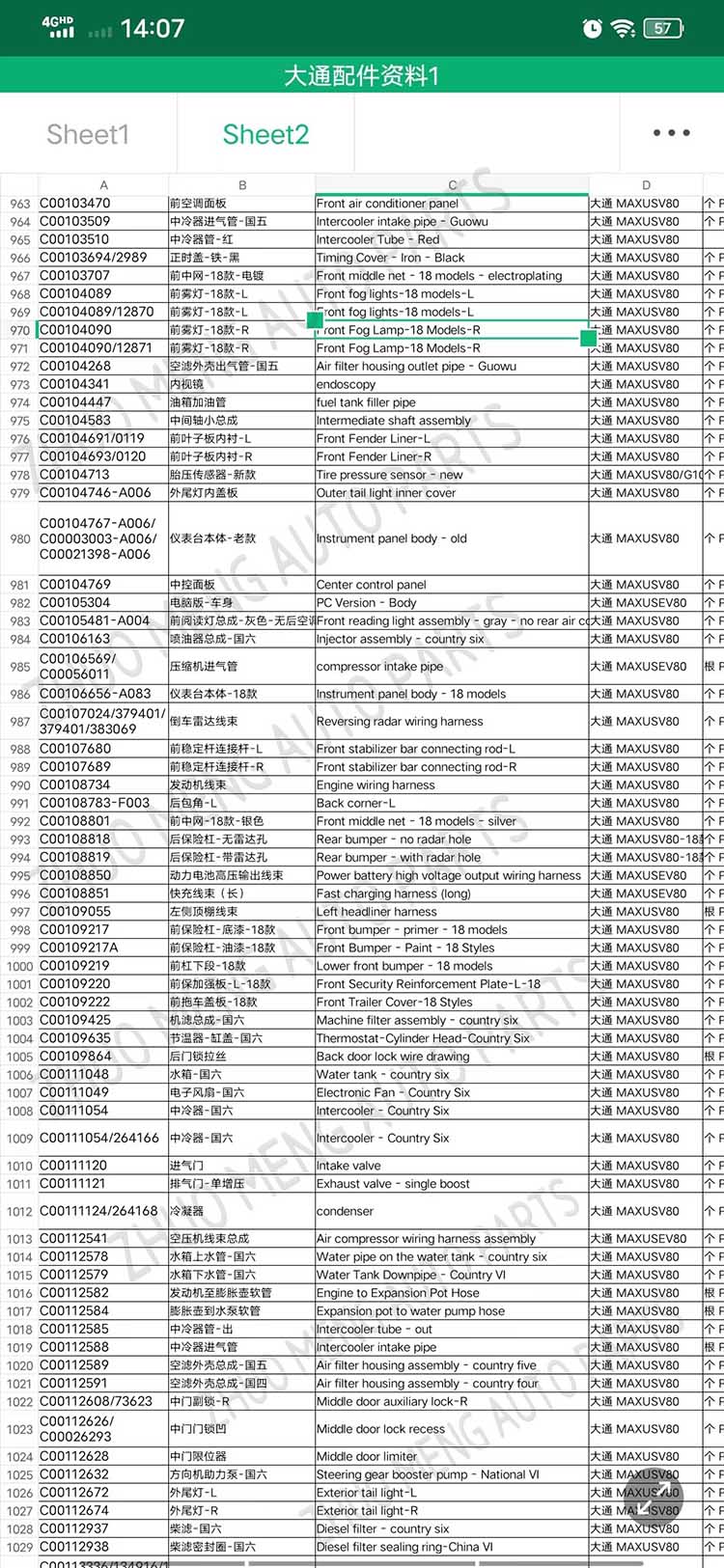

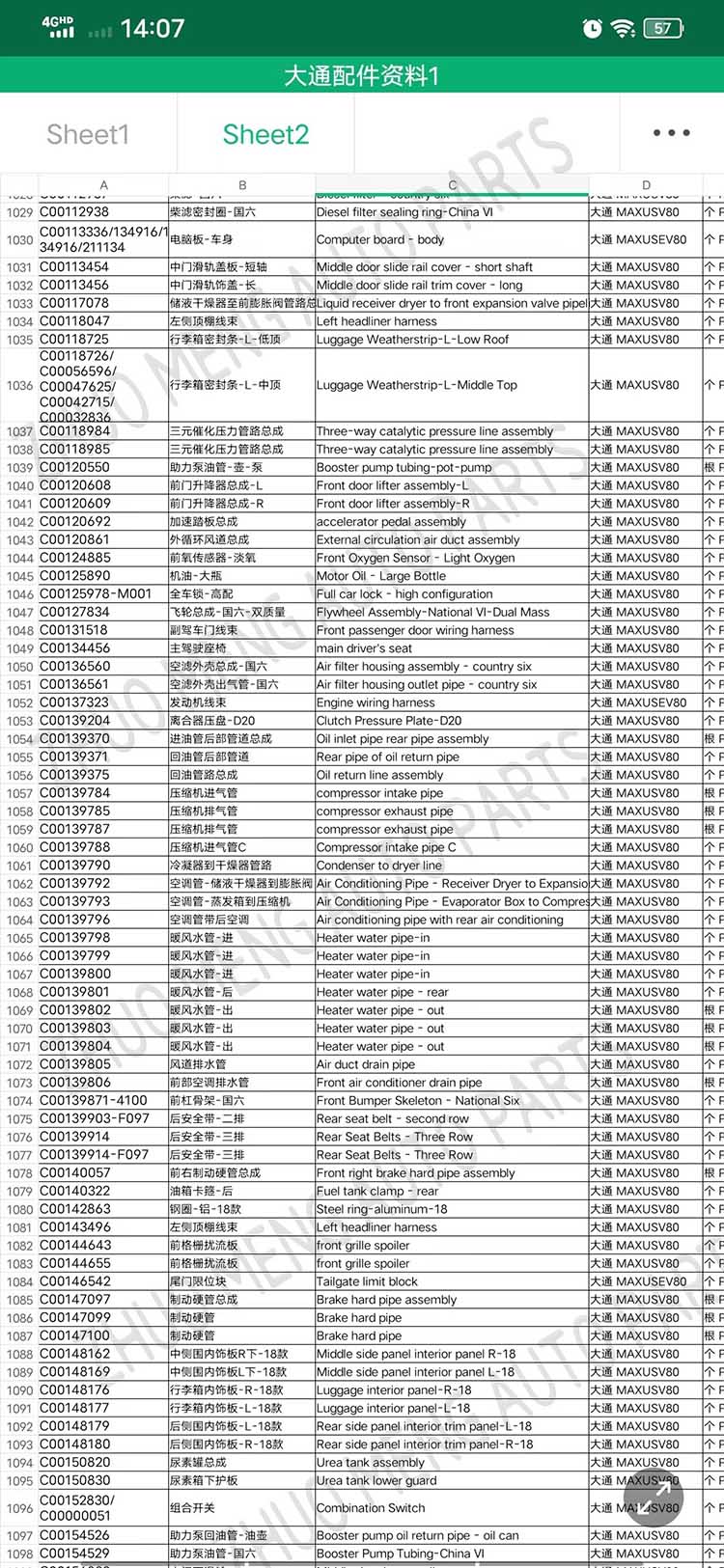

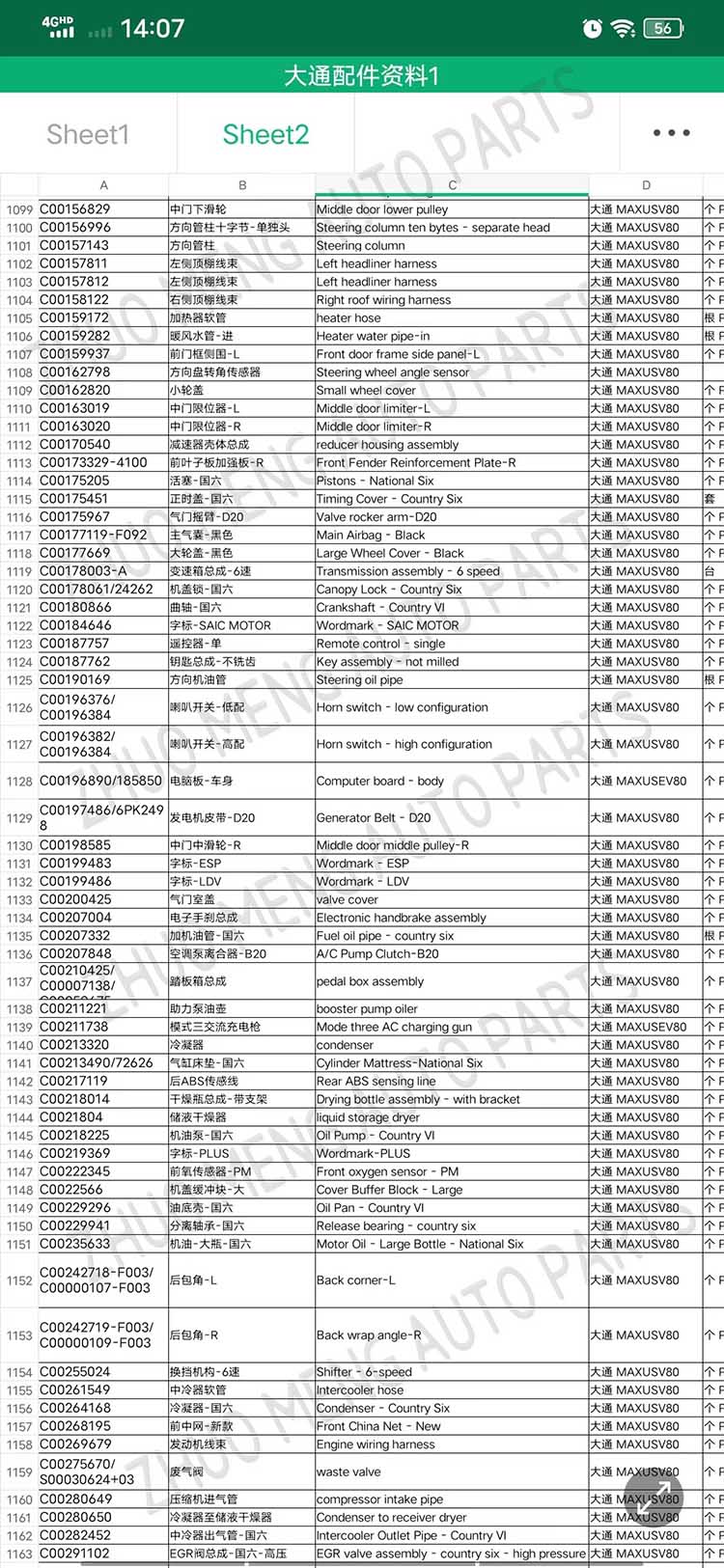

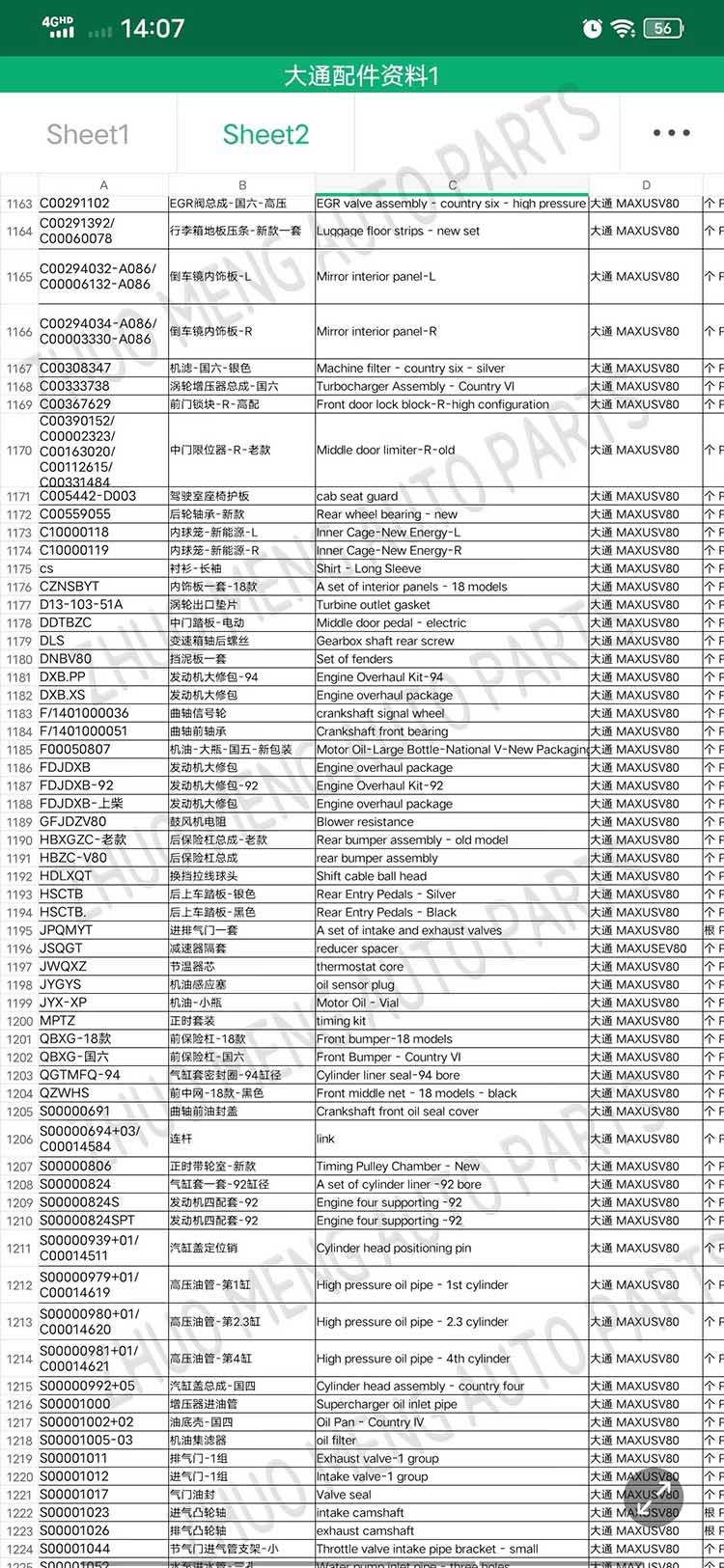

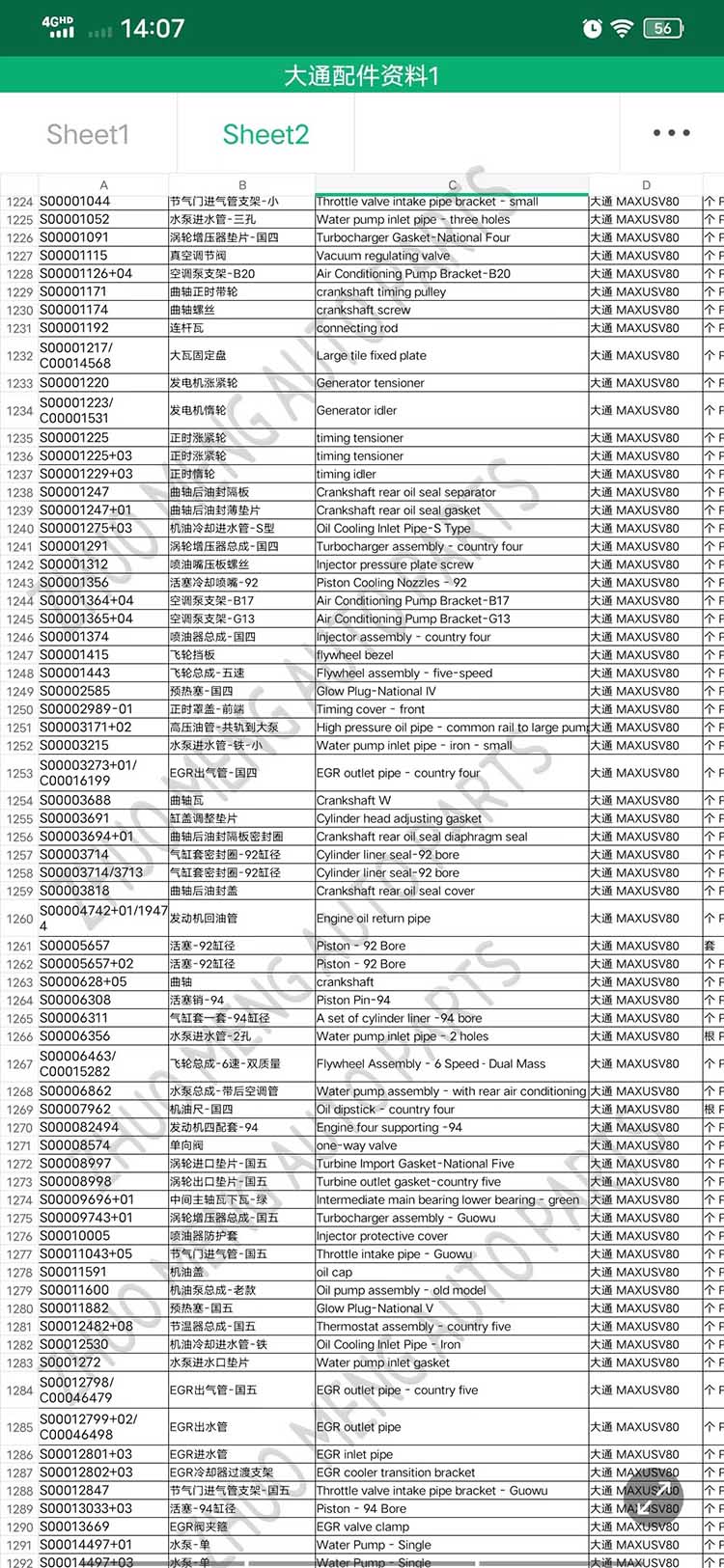

Products catalog

Related products

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for OEM/ODM China Mg Zx Spare Parts Factory - MAXUS AUTO PARTS SUPPLIER SAIC MAXUS V80 connecting rod C00014584/8203 – Zhuomeng , The product will supply to all over the world, such as: Dominica, Manila, Russia, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.