When people discuss three-wheeled motorcycles and some light trucks and vans, they often say that this axle is fully floating, and that axle is semi-floating. What do "full float" and "semi-float" mean here? Let us answer this question below.

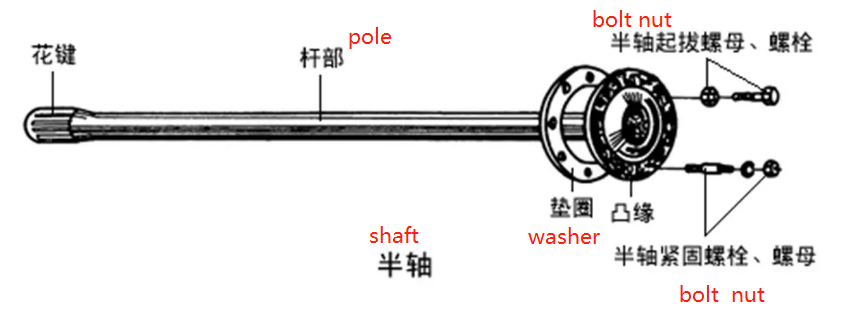

The so-called "full-floating" and "semi-floating" refer to the type of mounting support for the axle shafts of automobiles. As we all know, the half shaft is a solid shaft that transmits torque between the differential and the drive wheels. Its inner side is connected with the side gear through a spline, and the outer side is connected with the hub of the drive wheel with a flange. Since the half shaft needs to bear a very large torque, its strength is required to be very high. Generally, alloy steel such as 40Cr, 40CrMo or 40MnB is used for quenching and tempering and high-frequency quenching treatment. Grinding, the core has good toughness, can withstand large torque, and can withstand a certain impact load, which can meet the needs of automobiles under various conditions.

According to the different supporting types of the half shafts, the half shafts are divided into two types: "full floating" and "semi-floating". The full-floating axle and semi-floating axle we often refer to actually refer to the type of half-shaft. "Float" here refers to the bending load after the axle shaft is removed.

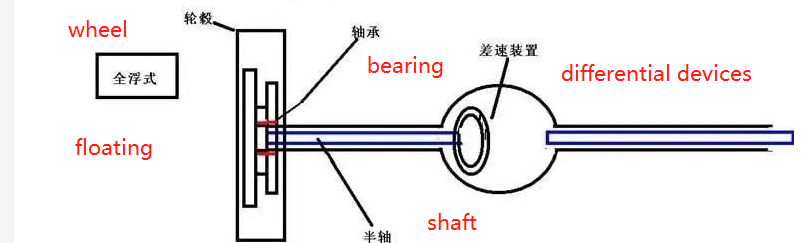

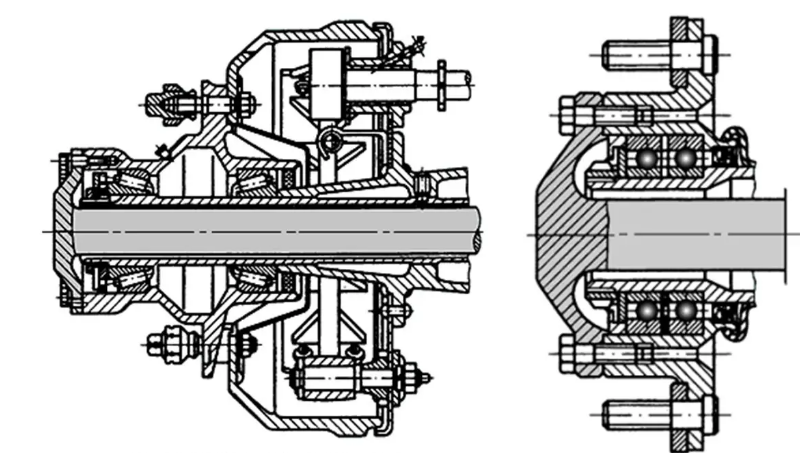

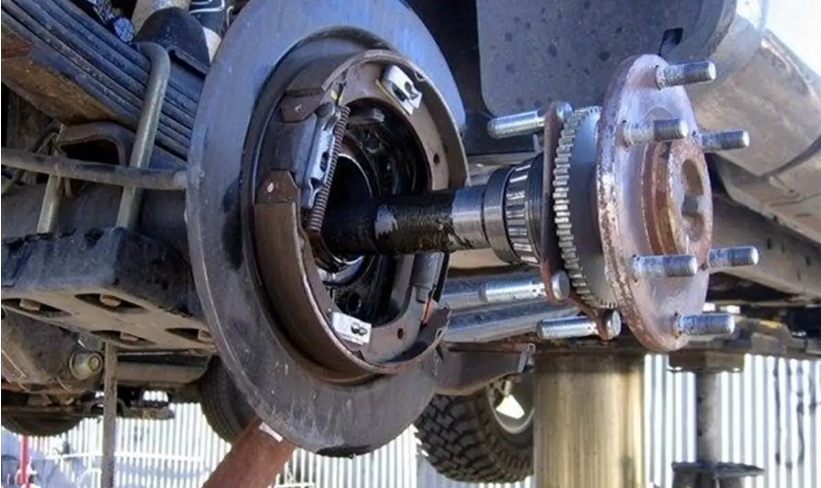

The so-called full-floating half shaft means that the half shaft only bears torque and does not bear any bending moment. The inner side of such a half shaft is connected with the differential side gear through splines, and the outer side has a flange plate, which is fixed with the wheel hub by bolts, and the wheel hub is mounted on the axle through two tapered roller bearings. In this way, various shocks and vibrations to the wheels, as well as the weight of the vehicle, are transmitted from the wheels to the hubs and then to the axles, which are ultimately borne by the axle housings. The axle shafts just transmit the torque from the differential to the wheels to drive the car. In this process, both ends of the half shaft only bear the torque without any bending moment, so it is called "full floating". The following figure shows the structure and installation of a full-floating half-shaft of an automobile. Its structural feature is that the wheel hub is installed on the axle through two tapered roller bearings, the wheel is installed on the wheel hub, the supporting force is directly transmitted to the axle, and the half-shaft passes through. Eight screws are attached to the hub and transmit torque to the hub, driving the wheel to turn.

The full-floating half shaft is easy to disassemble and replace, and the half shaft can be taken out only by removing the fixing bolts fixed on the flange plate of the half shaft. However, the entire weight of the car after removing the half-axle is supported by the axle housing, and it can still be parked on the ground reliably; the disadvantage is that the structure is relatively complex and the quality of the parts is large. It is the most widely used type in automobiles, and most light, medium and heavy trucks, off-road vehicles and passenger cars use this type of axle shaft.

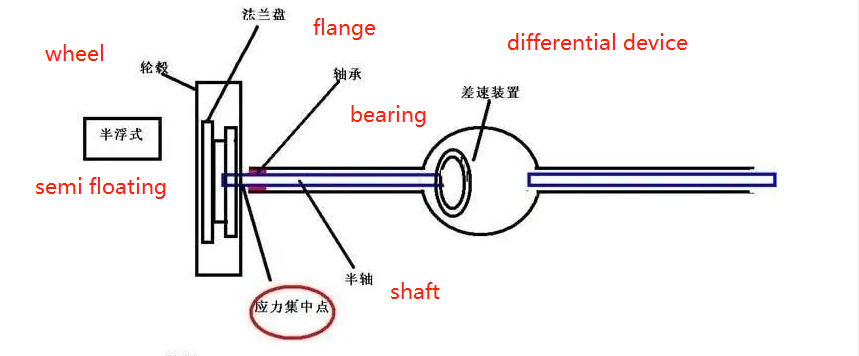

The so-called semi-floating half shaft means that the half shaft not only bears the torque, but also bears the bending moment. The inner side of such an axle shaft is connected with the differential side gear through splines, the outer end of the axle shaft is supported on the axle housing through a bearing, and the wheel is fixedly mounted on the cantilever at the outer end of the axle shaft. In this way, various forces acting on the wheels and the resulting bending moments are directly transmitted to the half shafts, and then to the drive axle housing through the bearings. When the car is running, the half shafts not only drive the wheels to rotate, but also drive the wheels to rotate. To support the full weight of the car. The inner end of the half shaft only bears the torque but not the bending moment, while the outer end bears both the torque and the full bending moment, so it is called "semi-floating". The following figure shows the structure and installation of a semi-floating semi-axle of an automobile. Its structural feature is that the outer end is fixed and supported on a tapered roller bearing with a tapered surface and a key and the hub, and the outward axial force is driven by the tapered roller bearing. Bearing, the inward axial force is transmitted to the tapered roller bearing of the other side half shaft through the slider.

The semi-floating half-shaft support structure is compact and light in weight, but the force of the half-shaft is complicated, and the disassembly and assembly are inconvenient. If the axle shafts are removed, the car cannot be supported on the ground. It can generally only be applied to small vans and light vehicles with small vehicle load, small wheel diameter and rear integral axle, such as the common Wu ling series and Song hua jiang series.

Post time: Aug-04-2022