New Fashion Design for Maxus G10 Spare Parts - Saic Maxusg10 And v80 t60 Rear Shock Absorber – Zhuomeng

New Fashion Design for Maxus G10 Spare Parts - Saic Maxusg10 And v80 t60 Rear Shock Absorber – Zhuomeng Detail:

Products Information

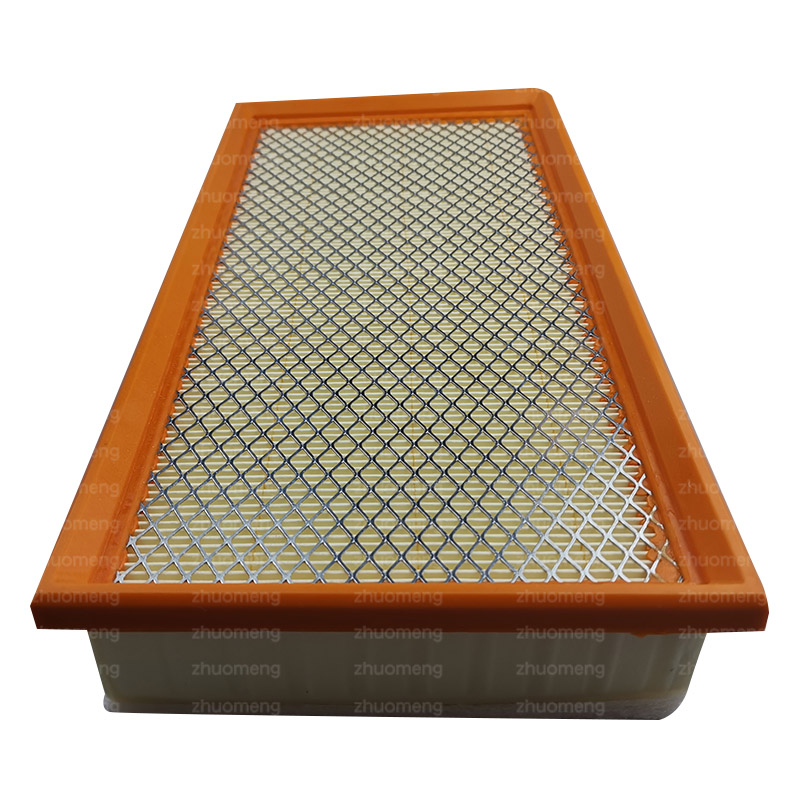

| Products Name | High Quality Brand Air Filter |

| Products Application | SAIC MAXUS V80 |

| Products OEM NO | C00032808 |

| Org Of Place | MADE IN CHINA |

| Brand | CSSOT / RMOEM / ORG / COPY |

| Lead Time | Stock, if less 20 PCS, normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Chassis system |

Product Knowledge

Type of air cleaner

According to the filtration principle, the air filter can be divided into filtration type, centrifugal type, oil bath type and composite type. The air filters commonly used in engines mainly include inertial oil bath air filter, paper dry air filter, polyurethane filter element air filter and so on. The inertia oil bath air filter has been filtered through three stages: inertia filter, oil bath filter and filter filter. The latter two kinds of air filters are mainly filtered through the filter element. Inertia oil bath air filter has the advantages of low air inlet resistance, can adapt to dusty and sandy working environment, long service life and so on. It was previously used in many types of automobile and tractor engines. However, this air filter has been gradually eliminated in automobile engines because of its low filtration efficiency, heavy weight, high cost and inconvenient maintenance. The filter element of paper dry air filter is made of microporous filter paper treated with resin. The filter paper is porous, loose and folded. It has certain mechanical strength and water resistance. It has the advantages of high filtration efficiency, simple structure, light weight, low cost and convenient maintenance. It is the most widely used automotive air filter at present. Polyurethane filter element the filter element of the air filter is made of soft, porous and spongy polyurethane with strong adsorption capacity. This air filter has the advantages of paper dry air filter, but it has low mechanical strength and is widely used in car engines. The disadvantages of the latter two air filters are short service life and unreliable operation under harsh environmental conditions.

Product Display

Advantages and disadvantages

All kinds of air filters have their own advantages and disadvantages, but there is inevitably a contradiction between air intake and filtration efficiency. With the in-depth study of air filter, the requirements for air filter are becoming higher and higher. Some new air filters have appeared, such as fiber filter element air filter, compound filter material air filter, silencing air filter, constant temperature air filter, etc., to meet the needs of engine work.

Product features

The use of paper core air filter in modern automobile engines is becoming more and more common, but some drivers still have prejudice against the paper core air filter and think that the filtering effect of the paper core air filter is not good. In fact, compared with oil bath air filter, paper core air filter has many advantages: first, the filtration efficiency is as high as 99.5% (98% for oil bath air filter), and the dust transmittance is only 0.1% – 0.3%; Second, the structure is compact and can be installed in any direction without being limited by the layout of vehicle parts; Third, the maintenance does not consume oil, but also saves a lot of cotton yarn, felt and metal materials; Fourth, small quality and low cost. Therefore, the driver can use it safely.

The key to using the paper core air filter well is to maintain its sealing performance and prevent unfiltered air from entering the engine cylinder from the bypass.

Installation and use

1. During installation, whether flange, rubber pipe connection or direct connection is adopted between the air filter and the engine inlet pipe, it must be tight and reliable to prevent air leakage, and rubber gaskets must be installed on both ends of the filter element; The wing nut for fixing the air filter cover cannot be tightened too tightly to avoid crushing the paper filter element.

2. During maintenance, the paper filter element must not be cleaned in oil, otherwise the paper filter element will fail and it is easy to cause flying accidents. During maintenance, only vibration method, soft brushing method (brush along its folds) or compressed air back blowing method can be used to remove dust and dirt attached to the surface of paper filter element. For the coarse filter, the dust at the dust collection part, blade and cyclone pipe shall be removed in time. Even if it can be maintained carefully every time, the paper filter element can not fully restore its original performance, and its air inlet resistance will increase. Therefore, generally, when the paper filter element needs the fourth maintenance, it should be replaced with a new filter element. If the paper filter element is broken, perforated or degummed between the filter paper and the end cover, it shall be replaced immediately.

3. When in use, it is necessary to strictly prevent the paper core air filter from getting wet by rain, because once the paper core absorbs a large amount of water, it will greatly increase the air inlet resistance and shorten the mission. In addition, the paper core air filter must not come into contact with oil and fire.

4. Some vehicle engines are equipped with cyclone air filter. The plastic cover at the end of the paper filter element is a deflector. The blades on the cover rotate the air. 80% of the dust is separated under the action of centrifugal force and collected in the dust collecting cup. The dust reaching the paper filter element is 20% of the inhaled dust, and the total filtration efficiency is about 99.7%. Therefore, when maintaining the cyclone air filter, be careful not to miss the plastic deflector on the filter element.

Customer evaluation

Maintenance

1. The filter element is the core component of the filter, which is made of special materials. It is a vulnerable part and needs special maintenance;

2. When the filter works for a long time, the filter element has intercepted certain impurities, which will lead to the increase of pressure and the decrease of flow. At this time, it needs to be cleaned in time;

3. When cleaning, be sure not to deform or damage the filter element.

Generally, the service life of the filter element is different according to the different raw materials used, but with the extension of service time, the impurities in the air will block the filter element, so generally speaking, the PP filter element needs to be replaced in three months; The activated carbon filter element needs to be replaced in six months; Because the fiber filter element cannot be cleaned, it is generally placed at the back end of PP cotton and activated carbon, which is not easy to cause blockage; Ceramic filter elements can usually be used for 9-12 months.

The filter paper in the equipment is also one of the keys. The filter paper in the high-quality filter equipment usually adopts microfiber paper filled with synthetic resin, which can effectively filter impurities and has strong pollution storage capacity. According to relevant statistics, about 1.5 kg of impurities were filtered out by the filtering equipment during the driving of a bus with an output power of 180 kW. In addition, the equipment also has great requirements for the strength of the filter paper. Due to the large air flow, the strength of the filter paper can resist the strong air flow, ensure the filtration efficiency and prolong the service life of the equipment

application area

1. In the machine tool industry, 85% of the machine tool transmission system adopts hydraulic transmission and control. Such as grinder, milling machine, planer, broaching machine, press, shearing machine, combined machine tool, etc.

2. In metallurgical industry, hydraulic technology is used in electric furnace control system, rolling mill control system, open hearth charging, converter control, blast furnace control, strip deviation and constant tension device.

3. Hydraulic transmission is widely used in construction machinery, such as excavator, tire loader, truck crane, crawler bulldozer, tire crane, self-propelled scraper, grader and vibratory roller.

4. Hydraulic technology is also widely used in agricultural machinery, such as combine harvester, tractor and plow.

5. In the automotive industry, hydraulic off-road vehicles, hydraulic dump trucks, hydraulic aerial work vehicles and fire engines all use hydraulic technology.

6. In the light textile industry, plastic injection molding machines, rubber vulcanizing machines, paper machines, printing machines and textile machines adopt hydraulic technology.

Test standard

(1) ISO 2942 hydraulic fluid power – filter elements – Determination of structural integrity

(2) ISO 16889 hydraulic fluid power – Filters – multiple pass method for the determination of filtration characteristics

(3) ISO 3968 hydraulic fluid power – Filters – Determination of pressure drop and flow characteristics

(4) ISO 3724 hydraulic fluid power – filter elements – Determination of flow fatigue characteristics

(5) ISO 3723 hydraulic fluid power – filter elements – axial load test method

(6) ISO 2943 hydraulic fluid power – filter elements – Verification of compatibility between materials and liquids

(7) ISO 2941 hydraulic fluid power – filter elements – Verification of rupture resistance

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for New Fashion Design for Maxus G10 Spare Parts - Saic Maxusg10 And v80 t60 Rear Shock Absorber – Zhuomeng , The product will supply to all over the world, such as: Indonesia, Kuala Lumpur, Kuwait, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.