Manufacturing Companies for Mgrx5 Ev Auto Parts Wholesale - wholesale supplier SAIC MAXUS V80 Transmission fifth gear – 5 speed C00013867 – Zhuomeng

Manufacturing Companies for Mgrx5 Ev Auto Parts Wholesale - wholesale supplier SAIC MAXUS V80 Transmission fifth gear – 5 speed C00013867 – Zhuomeng Detail:

Products information

| Products name | SAIC MAXUS V80 Transmission fifth gear – 5 speed |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C00013867 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Cool system |

Products knowledge

Gearbox tooth beating is actually a hard collision between two metal gears. The final result is obvious, that is, the tooth crown part of the gear is caused to wear faster. After a long time and many times, the originally right-angle tooth crown will be damaged. Grind into a rounded corner, the bite is not complete after entering the gear, and it is easy to lose the gear after a little vibration. At this time, the gearbox needs to be overhauled.

Gearbox beating

Gearbox tooth beating is actually a hard collision between two metal gears. The final result is obvious, that is, the tooth crown part of the gear is caused to wear faster. After a long time and many times, the originally right-angle tooth crown will be damaged. Grind into a rounded corner, the bite is not complete after entering the gear, and it is easy to lose the gear after a little vibration. At this time, the gearbox needs to be overhauled.

Reason

Gearbox gears are damaged due to misoperation. As far as automobile gearboxes are concerned, it is generally required to step on the clutch to the end during manual shifting, and then perform the shifting operation. When the speed of the vehicle and the engine are basically the same, loosen the Open the clutch and complete the gear shift. Under what circumstances is it easy to hit the teeth? Often the clutch is not completely disengaged, and the gear shifting operation is carried out. Not only the gear noise occurs during gear shifting, but also it is easy to cause tooth knocking. In addition, if there are large impurities in the lubricating oil in the gearbox, such as iron filings that have been worn for a long time, if the gear rotates, if the It is caught in the middle of the transmission gear, and it is also easy to cause tooth punching.

There is a very important device inside the structure of the manual transmission, which is the “synchronizer”. The function of the synchronizer is very obvious, that is, when shifting gears, the gear speed at the power output end is faster than the gear that is about to be shifted into this gear. If there is no synchronizer, a slow rotating gear is forcibly inserted into a high-speed gear. In the rotating gear, the phenomenon of tooth knocking will definitely occur.

The function of the synchronizer is to increase the speed of the gear that is about to be shifted into the gear to be synchronized with the speed of the output gear when the shifting action occurs, so that there will be no tooth slap when shifting.

I understand that the phenomenon of slaps occurs, so why do many cars do not have slaps when they are driving forward, but do slaps as soon as they are in reverse gear? That’s because the reverse gear of many models is not equipped with a reverse gear synchronizer, because in the manufacturer’s concept, the reverse gear needs to be completely stopped and then engaged, and the opportunity to use it is relatively small, so in order to simplify the gearbox structure and For the purpose of saving cost, many middle and low-end manual transmissions do not have reverse synchronizers installed in their reverse gears.

Manual transmissions without a reverse synchronizer will have the phenomenon of engaging the reverse gear and knocking teeth. Of course, this is also closely related to the user’s usage habits, because the reverse gear itself does not contain a synchronizer, and the vehicle needs to be completely stopped to reduce the speed of the power output to the reverse gear (the reverse gear is stationary at this time). ) The speed difference between ) becomes smaller, so as to ensure that the reverse gear is relatively smooth and there is no slap in the teeth. Many users rush into the reverse gear immediately before the car is stopped, which will naturally cause the reverse gear without the synchronizer to be very injured, and the tooth strike will occur.

The dangers of teething

Teeth beating is actually a hard collision between two metal gears. The final result is obvious, that is, the crown part of the gear will wear faster. After a long time and many times, the crown of the right angle will be ground. It becomes a rounded corner, and the bite is not complete after entering the gear. It is easy to lose gear after a little vibration. At this time, the gearbox needs to be overhauled.

Avoid reverse gearing

Stopping the car completely before reversing is the best way to prevent gear knocking. At the same time, be sure to step on the clutch to the end, and you must not step on the clutch halfway because you are lazy, which will cause serious reverse gear knocking. Tooth, even if there is a forward gear with a synchronizer, don’t be too superstitious. The synchronizer will make the gear shift extremely smooth. If you don’t press the clutch thoroughly, no matter how good the synchronizer is, it will not be able to withstand a large speed difference. The wear will be accelerated geometrically.

Entry Atlas

OUR EXHIBITION

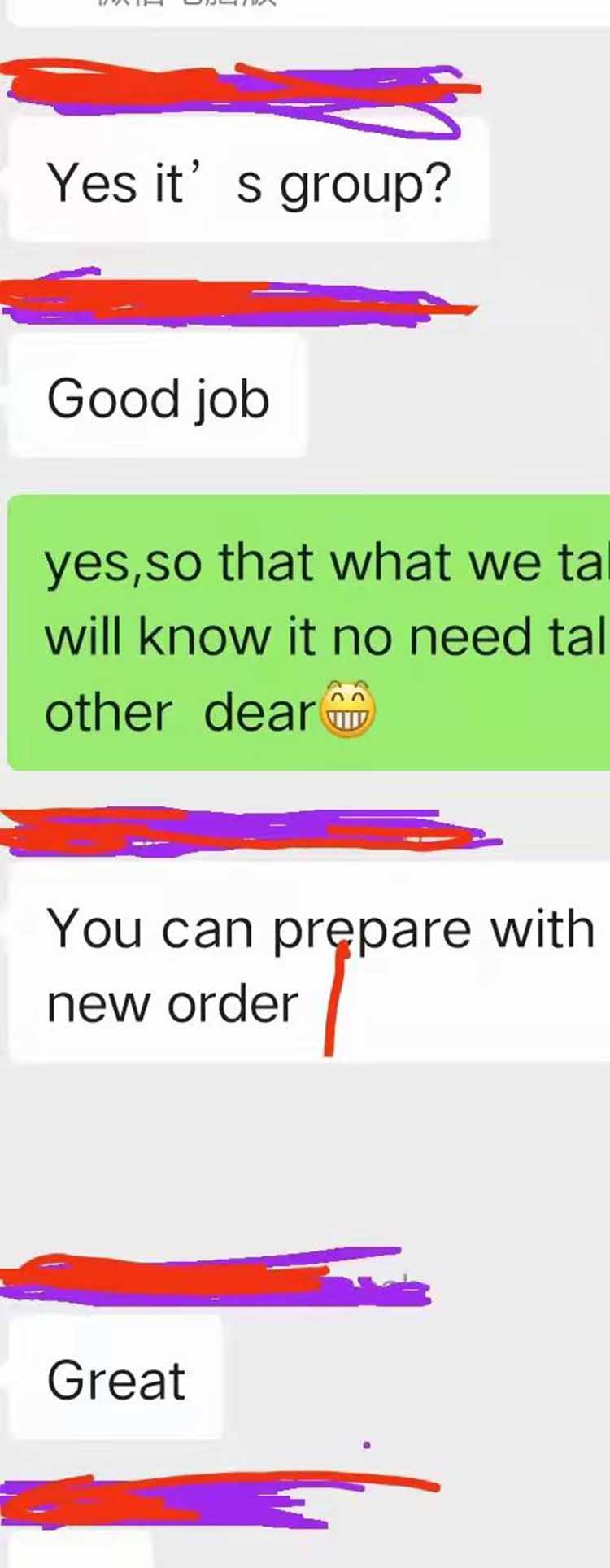

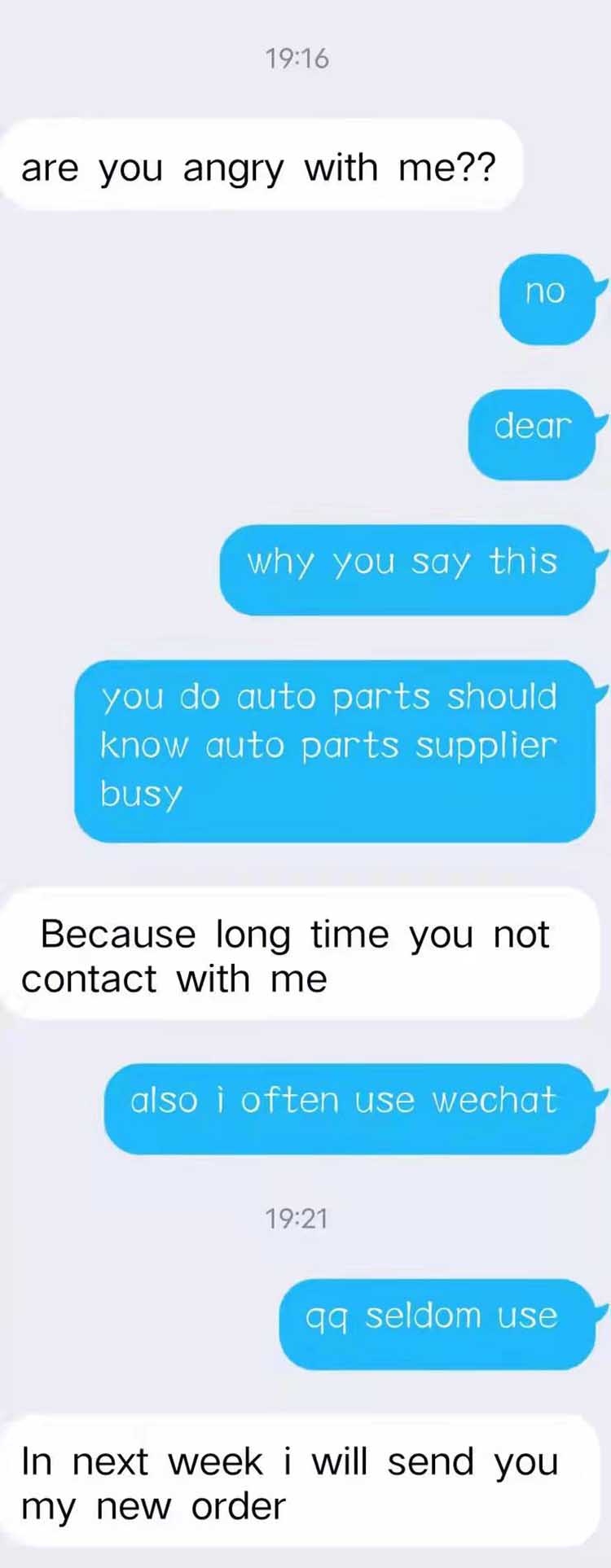

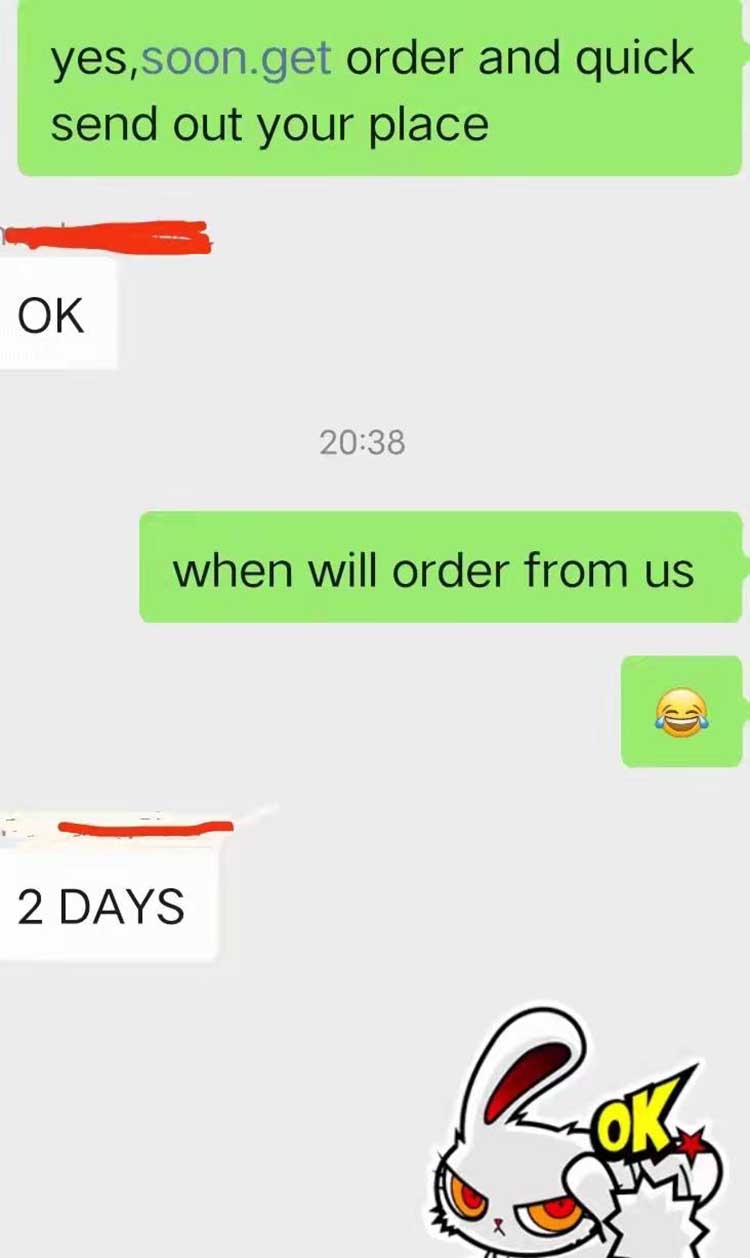

Good Feetback

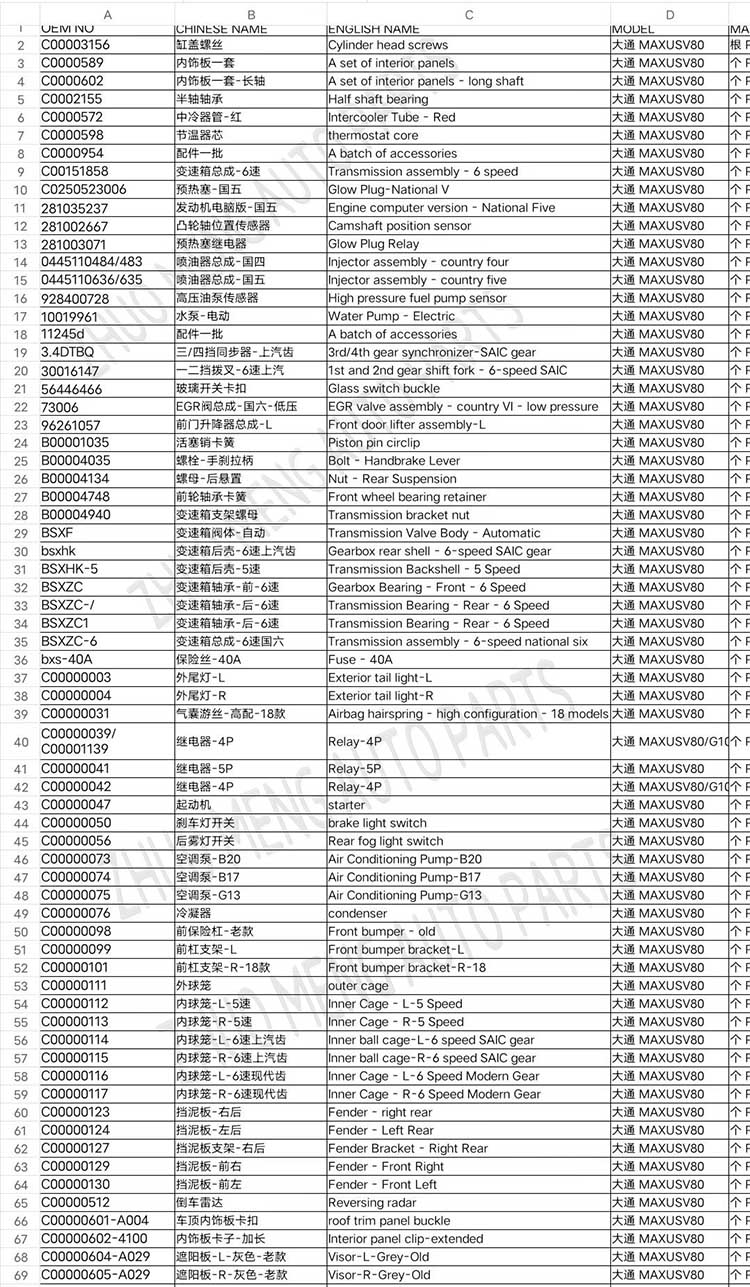

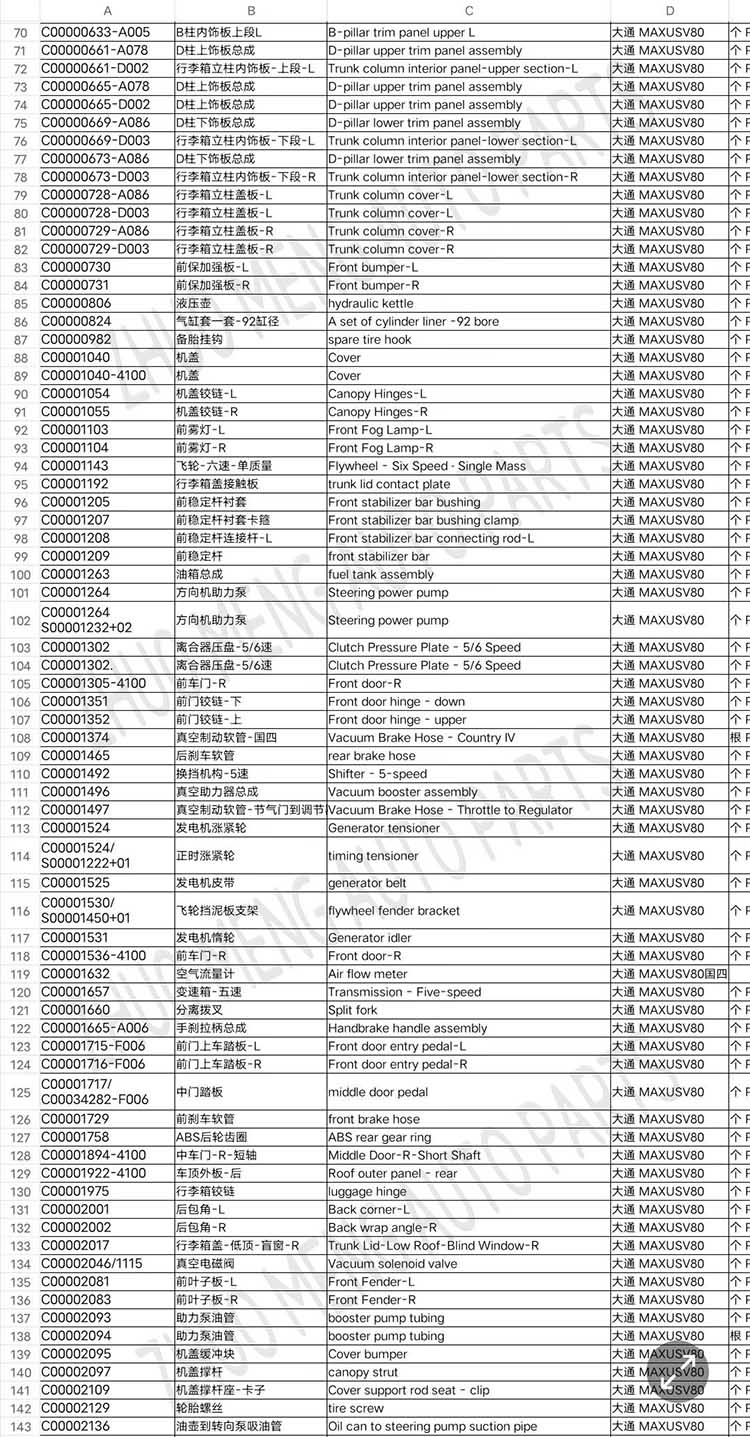

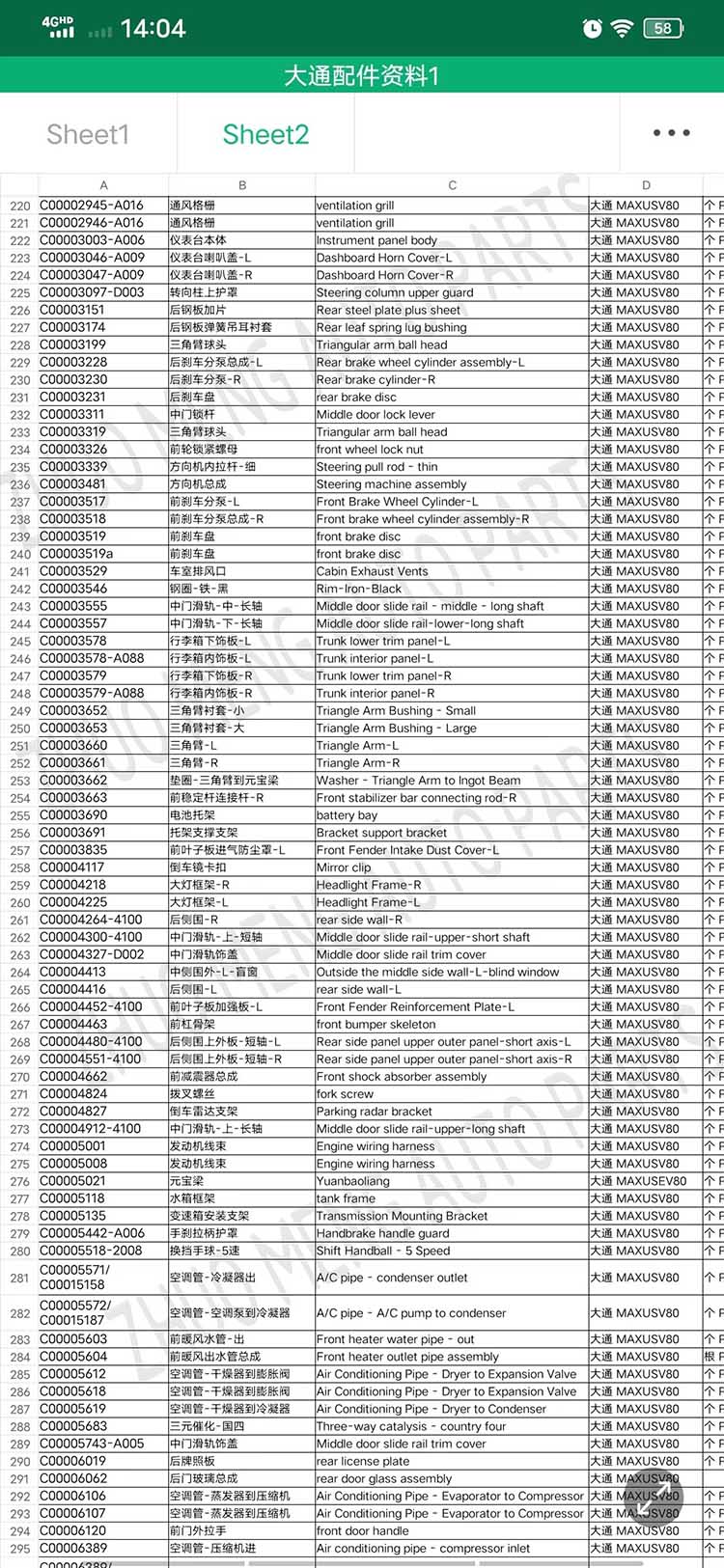

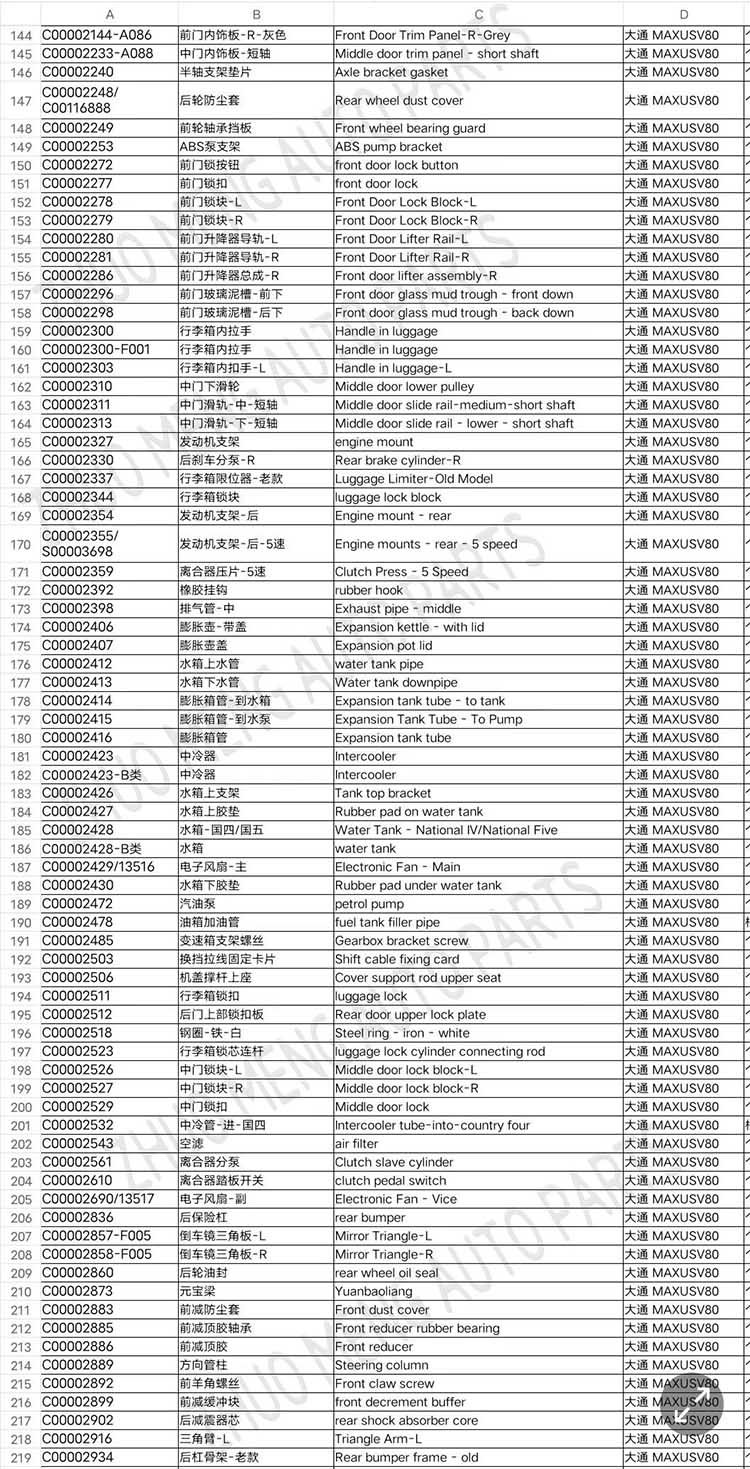

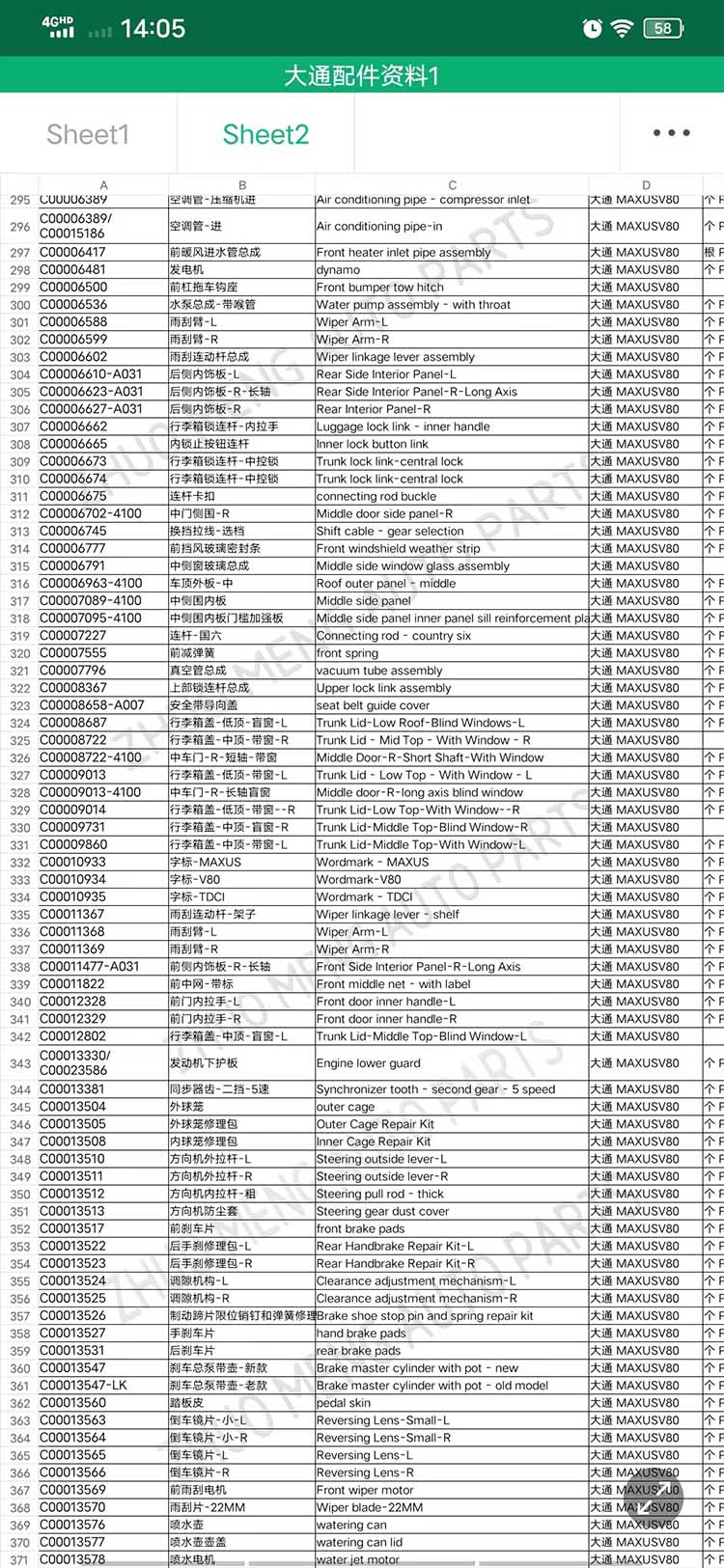

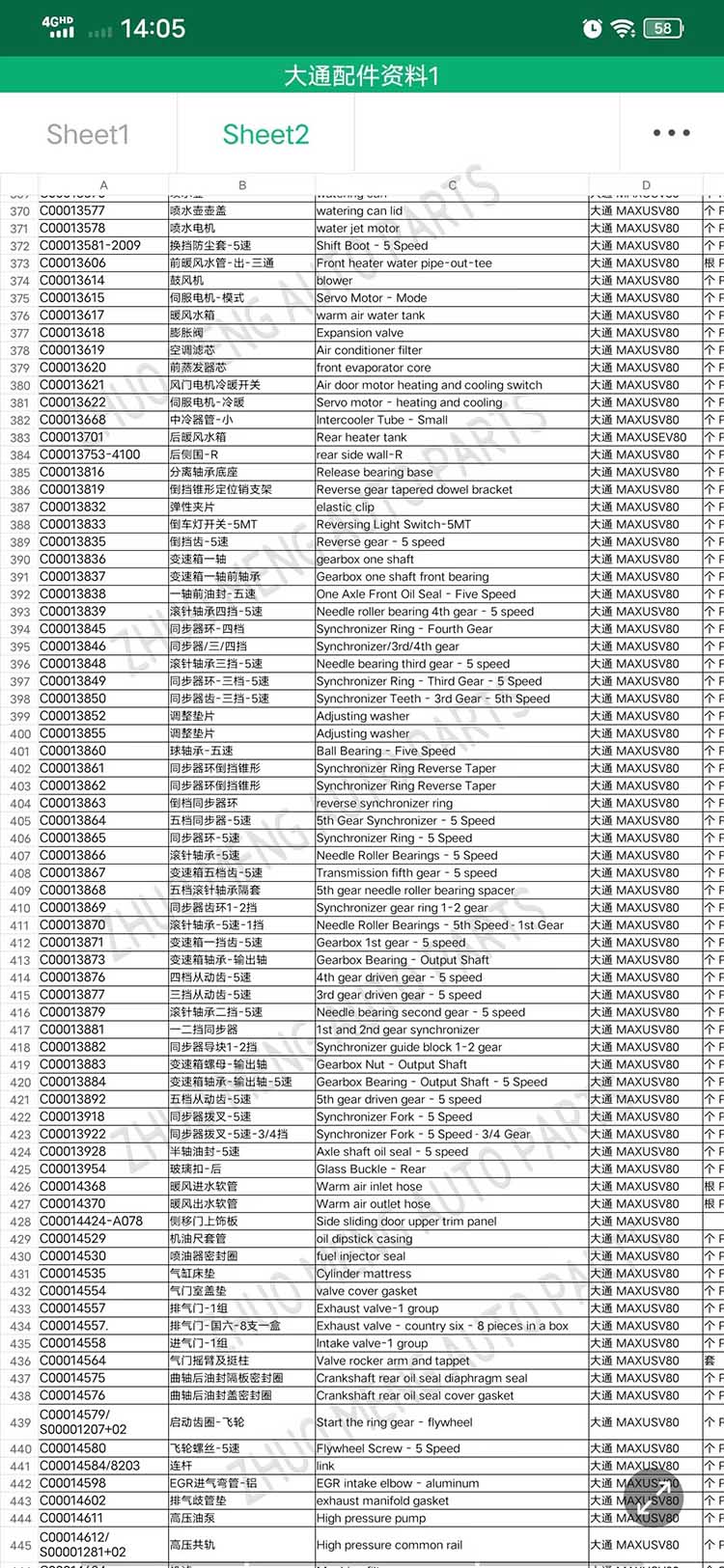

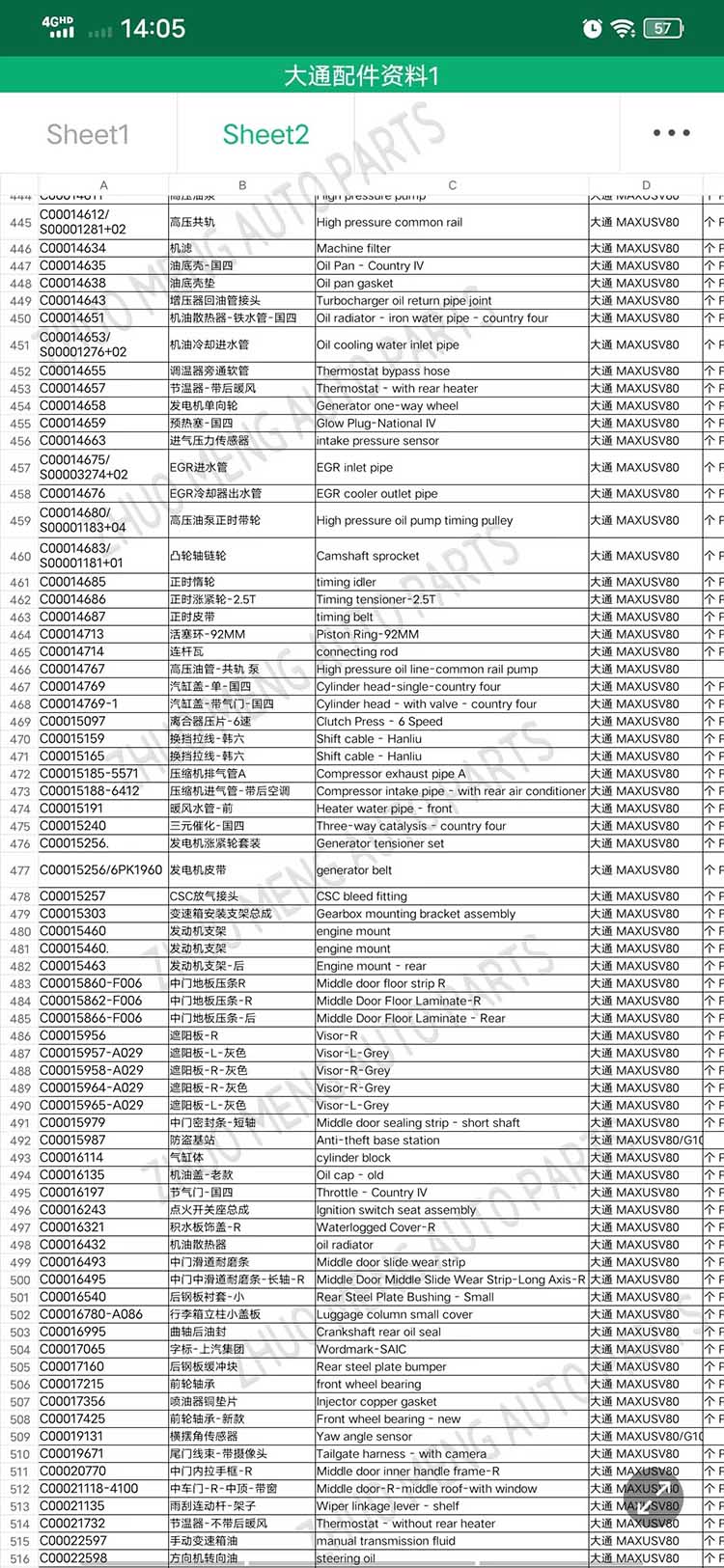

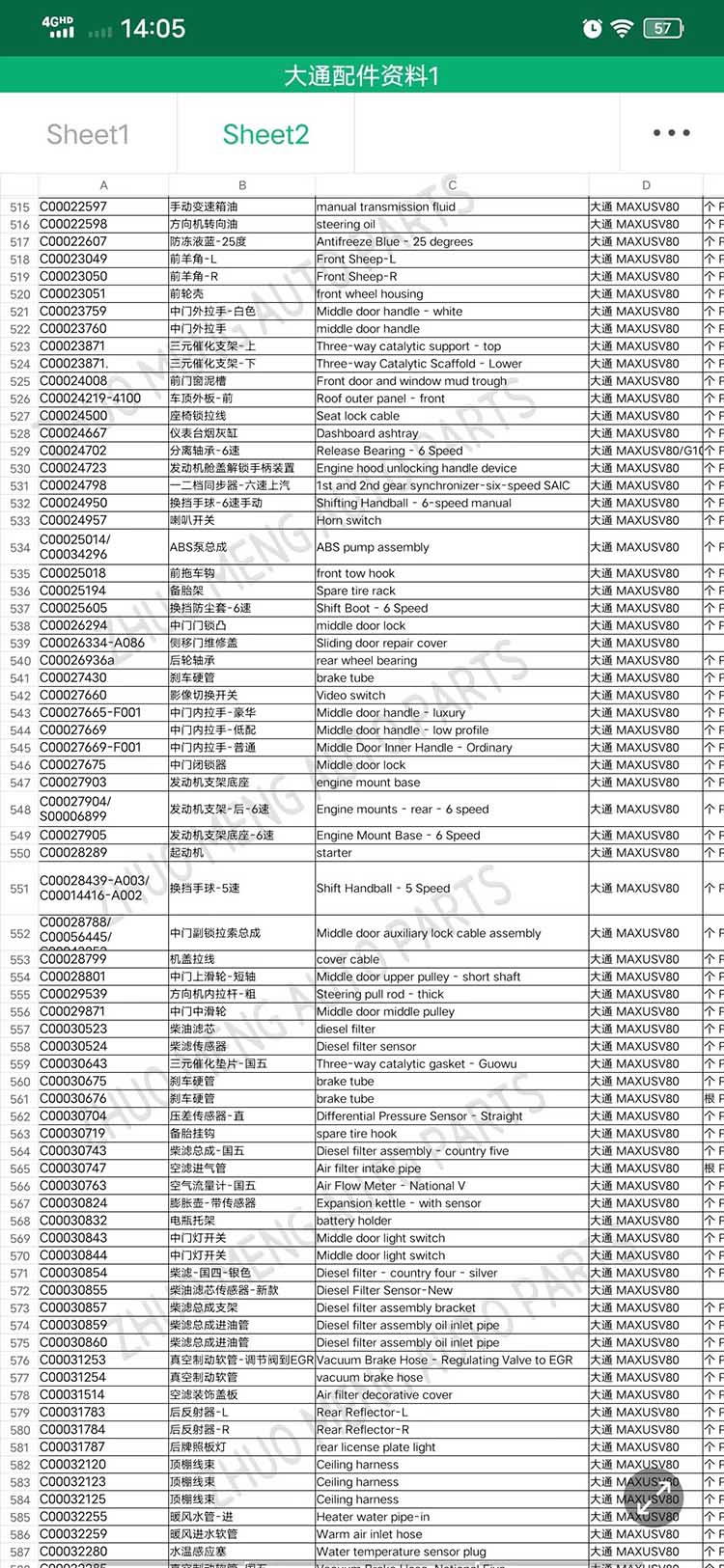

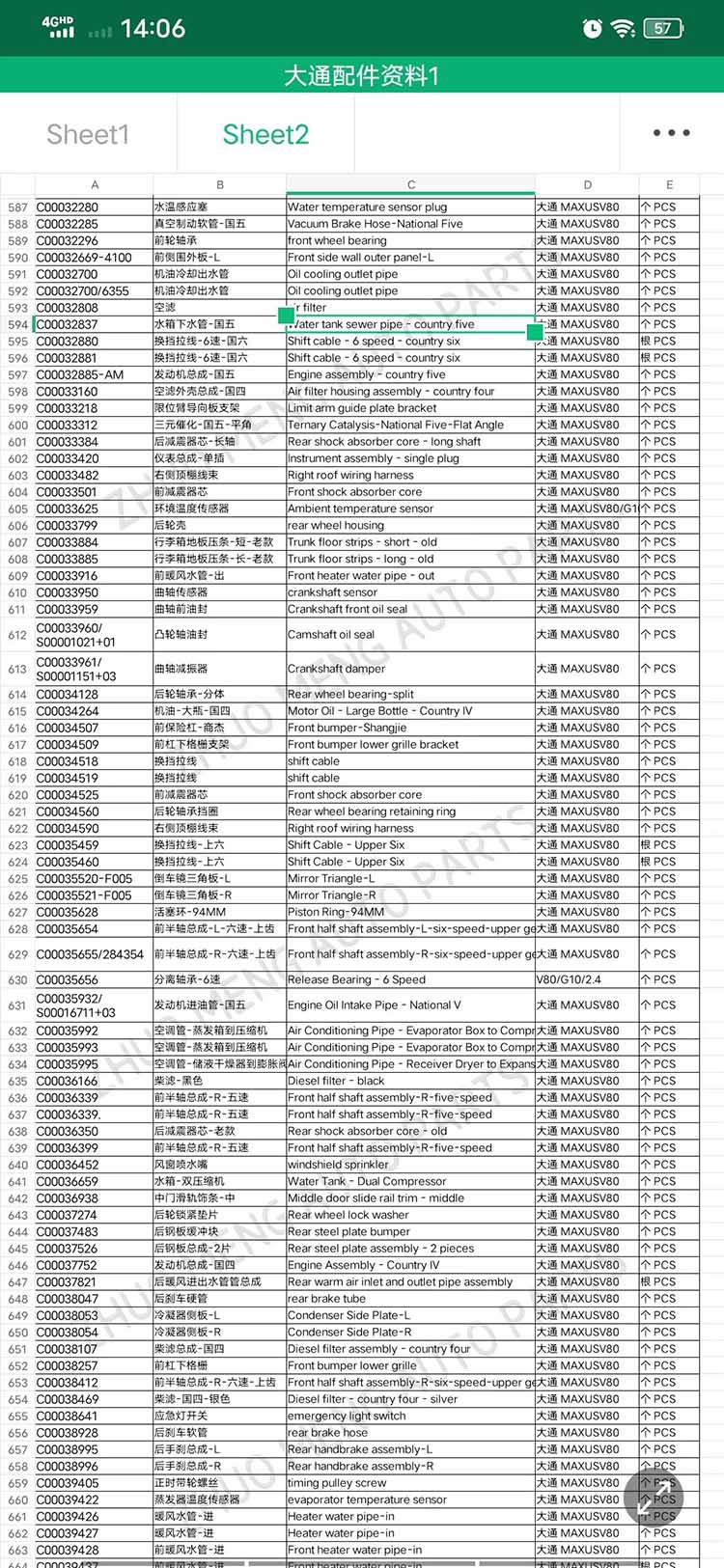

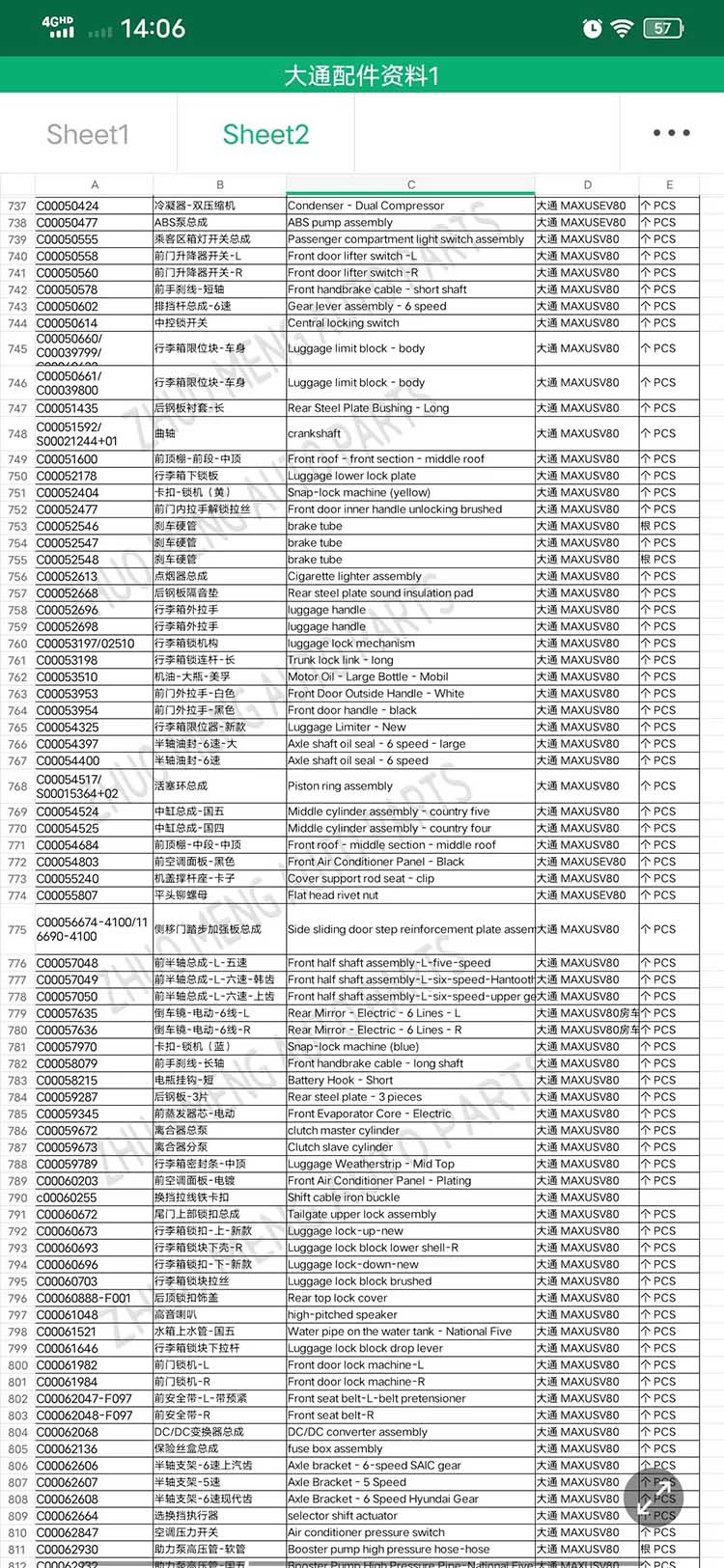

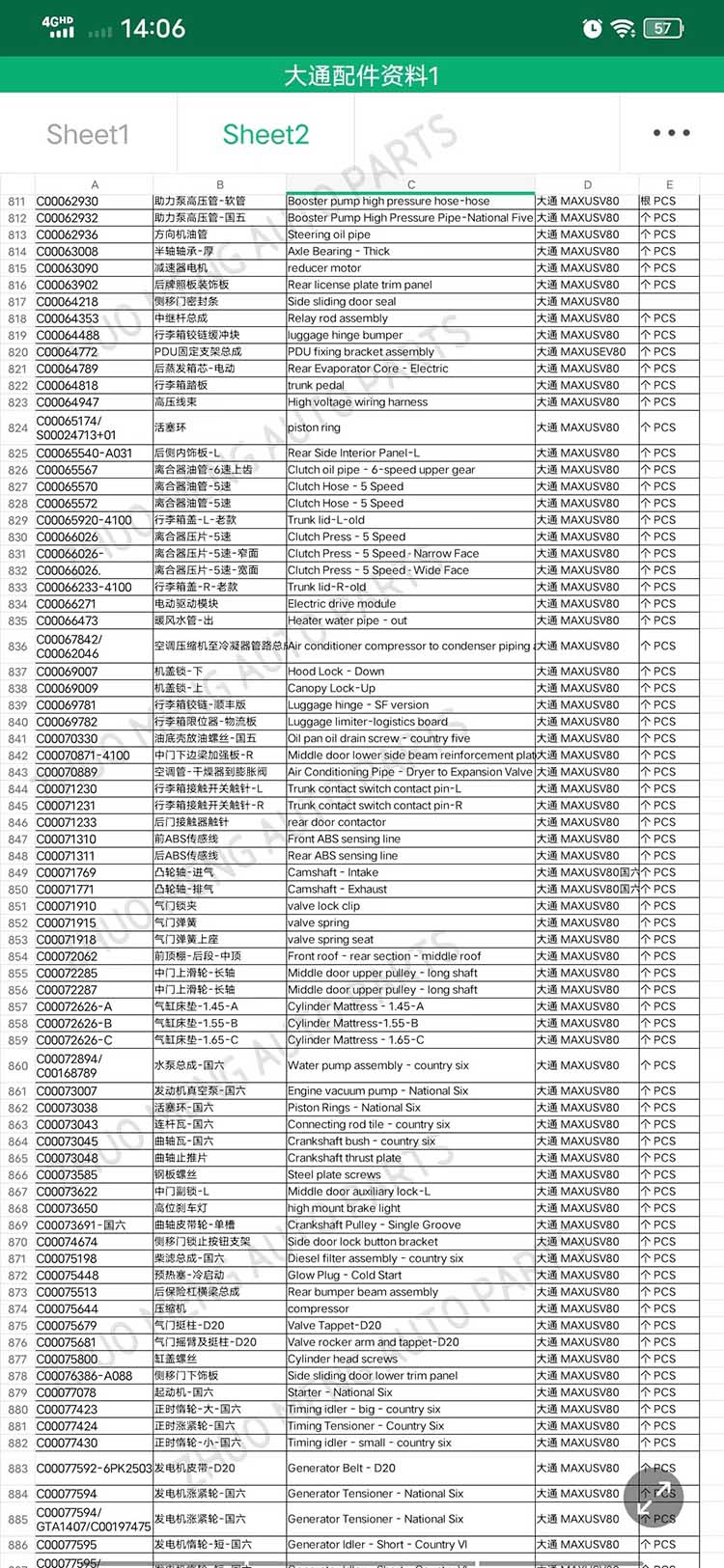

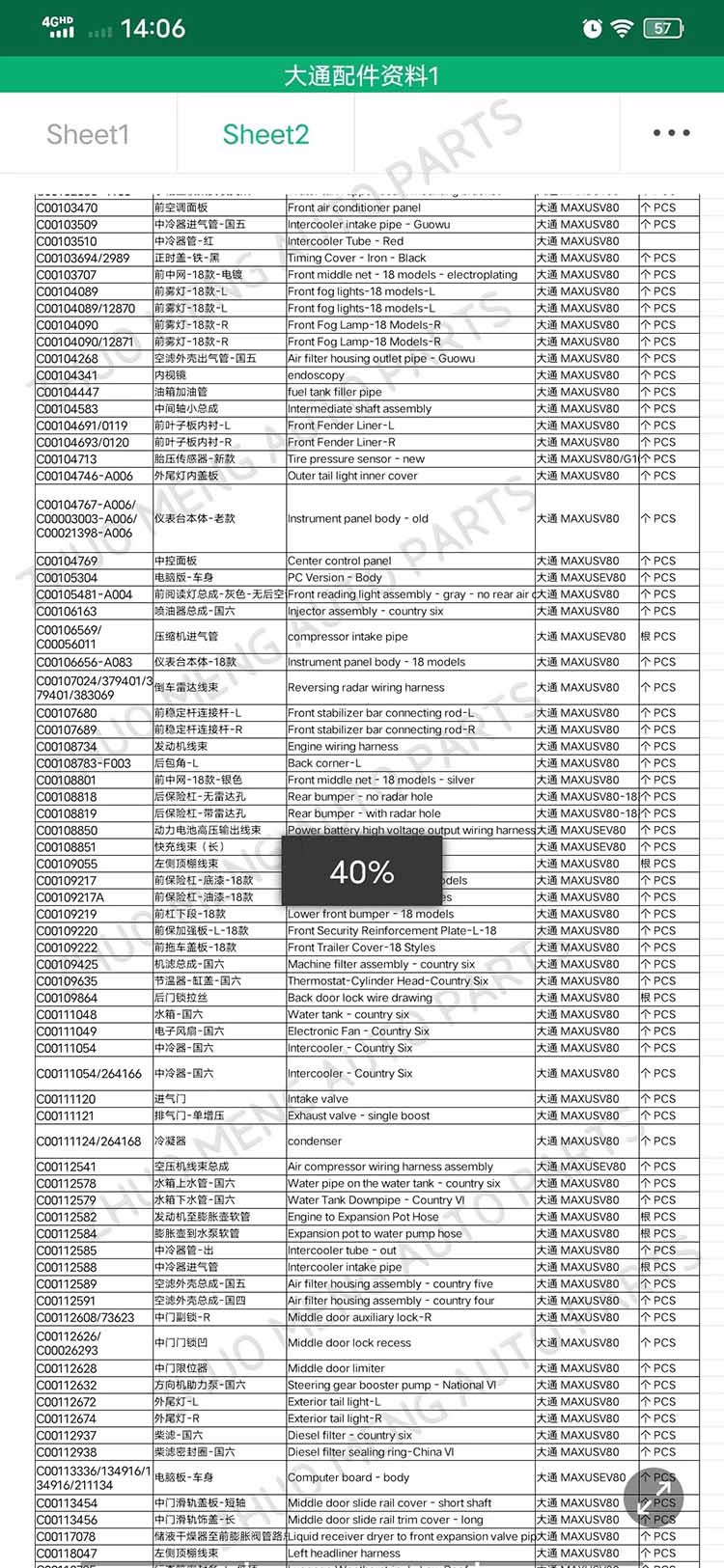

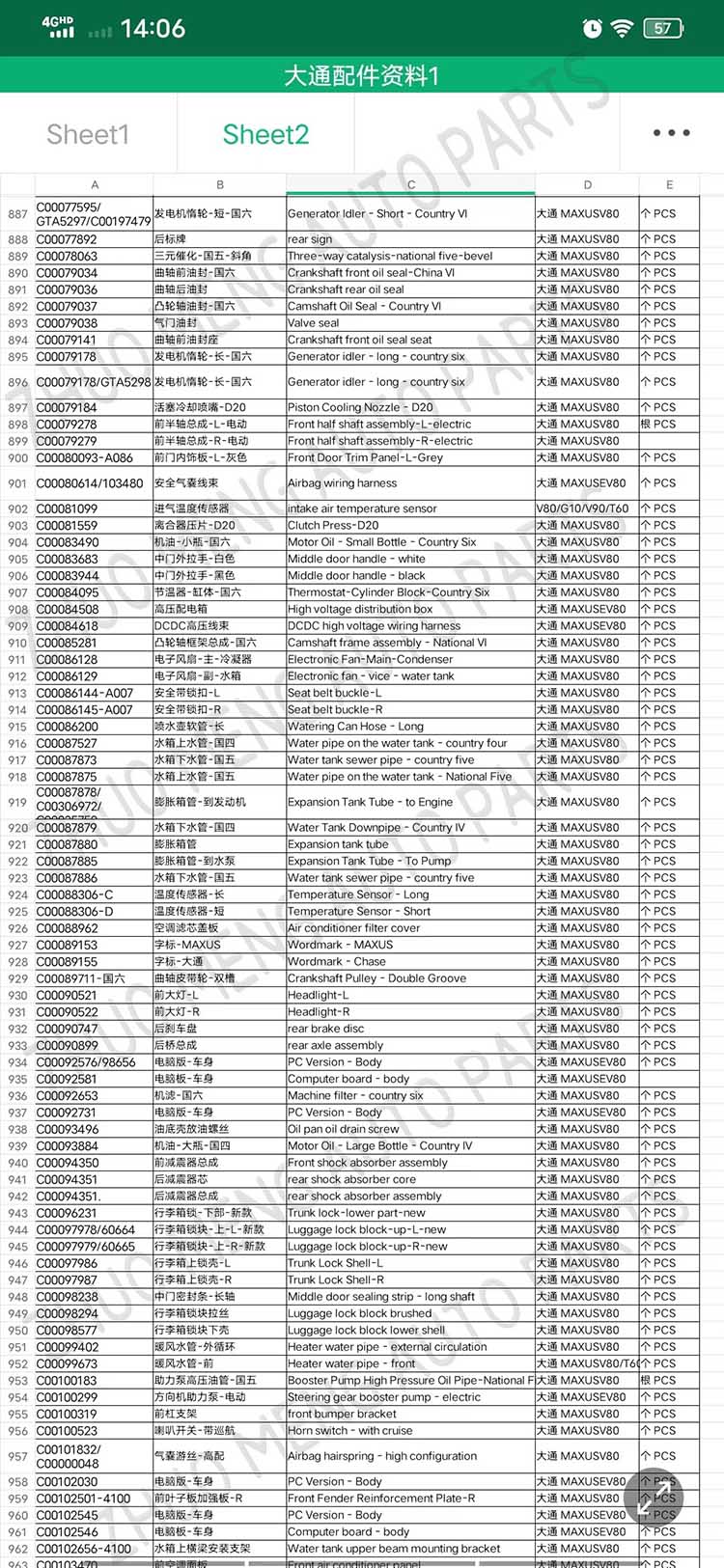

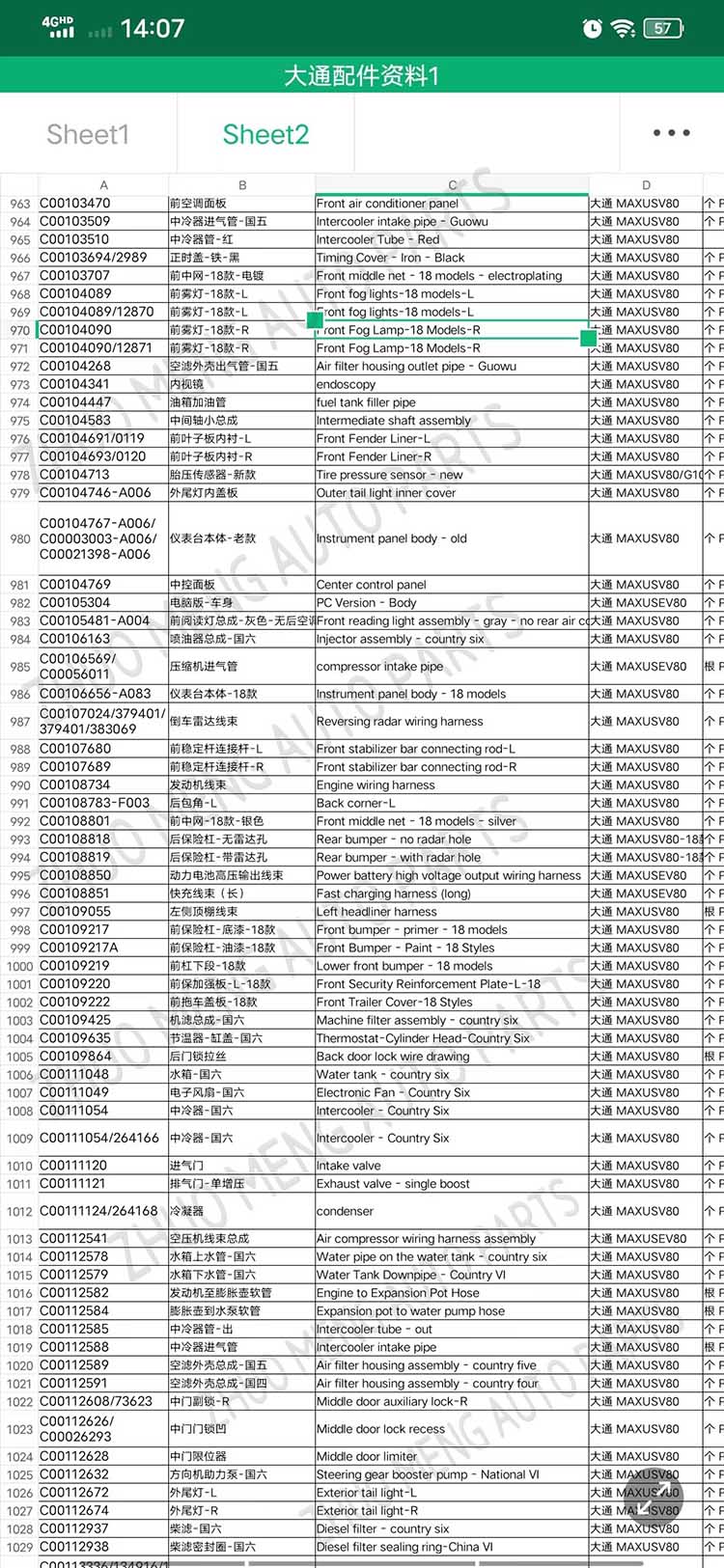

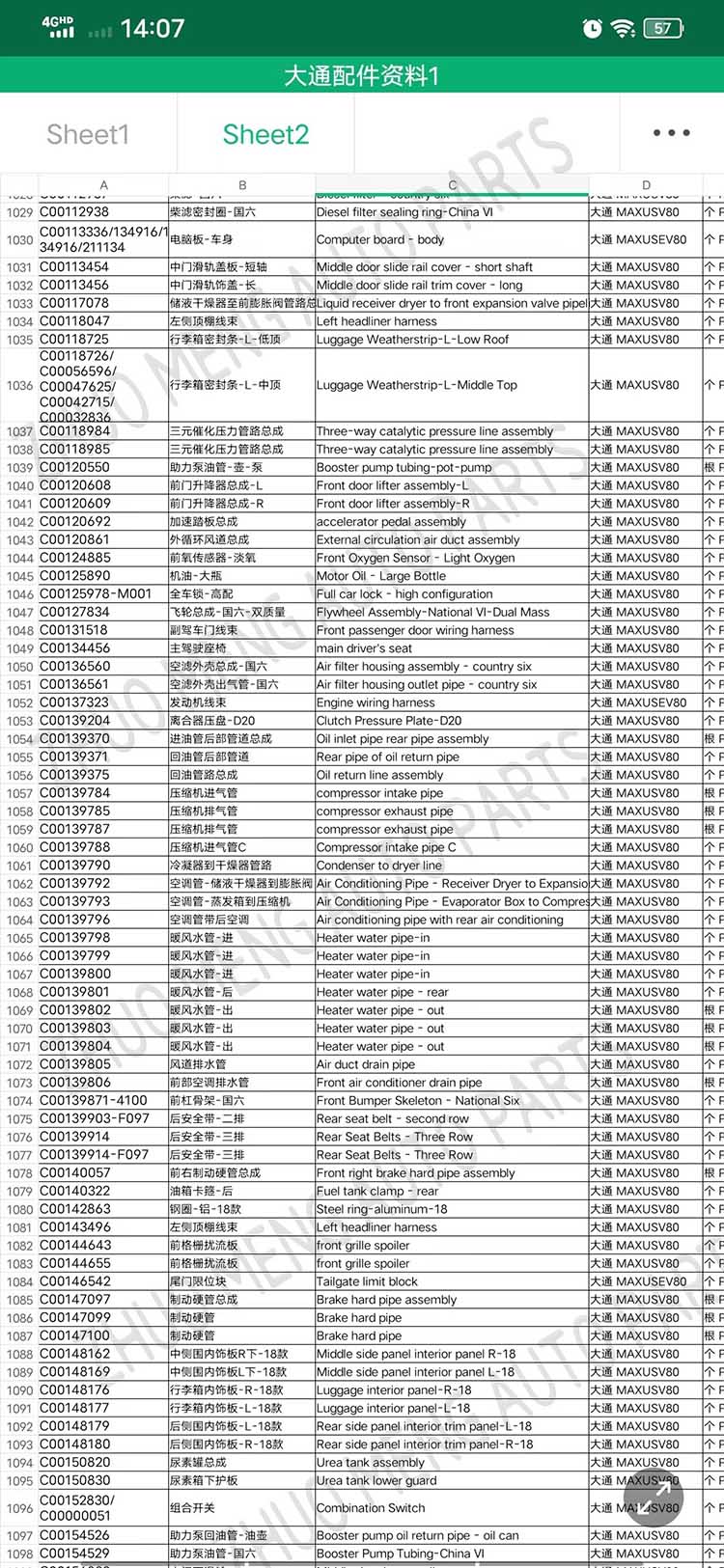

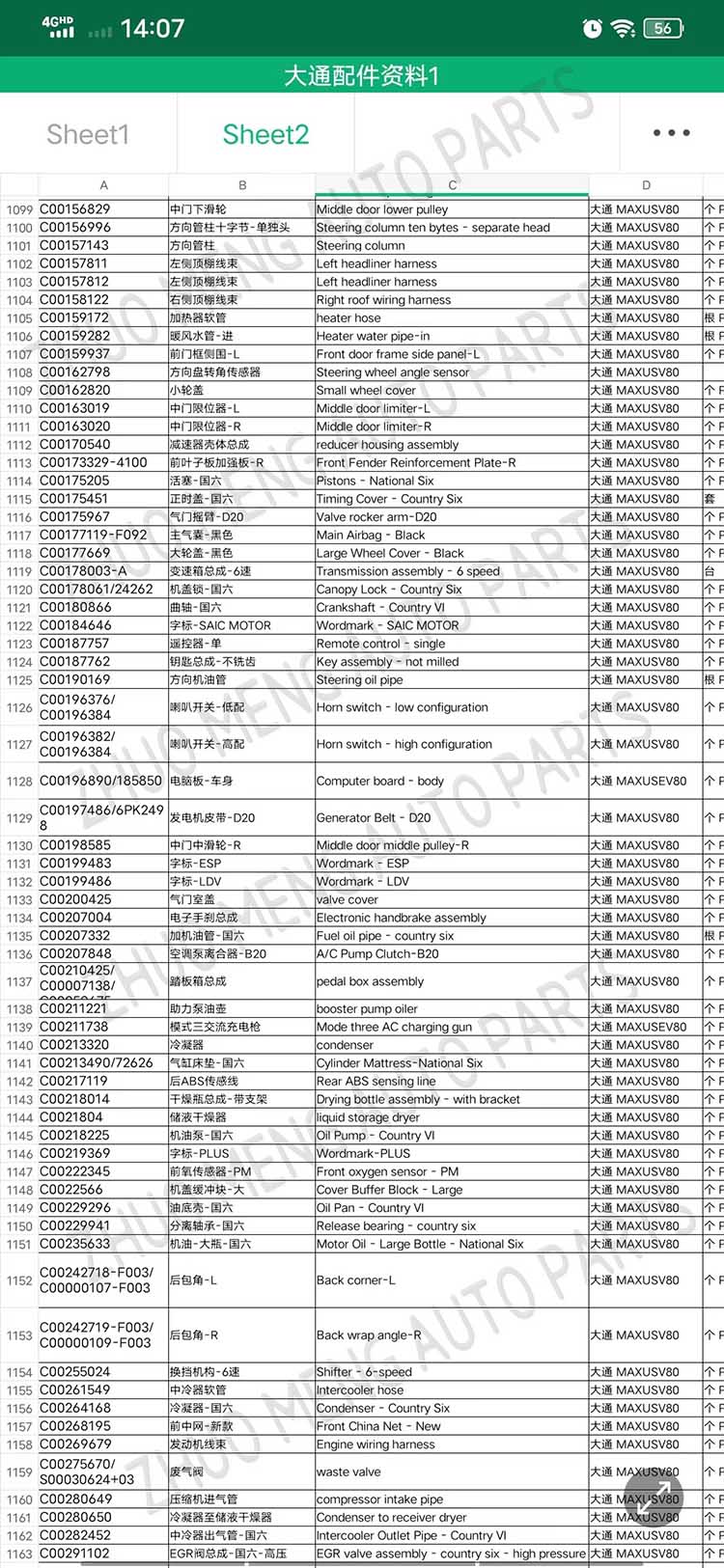

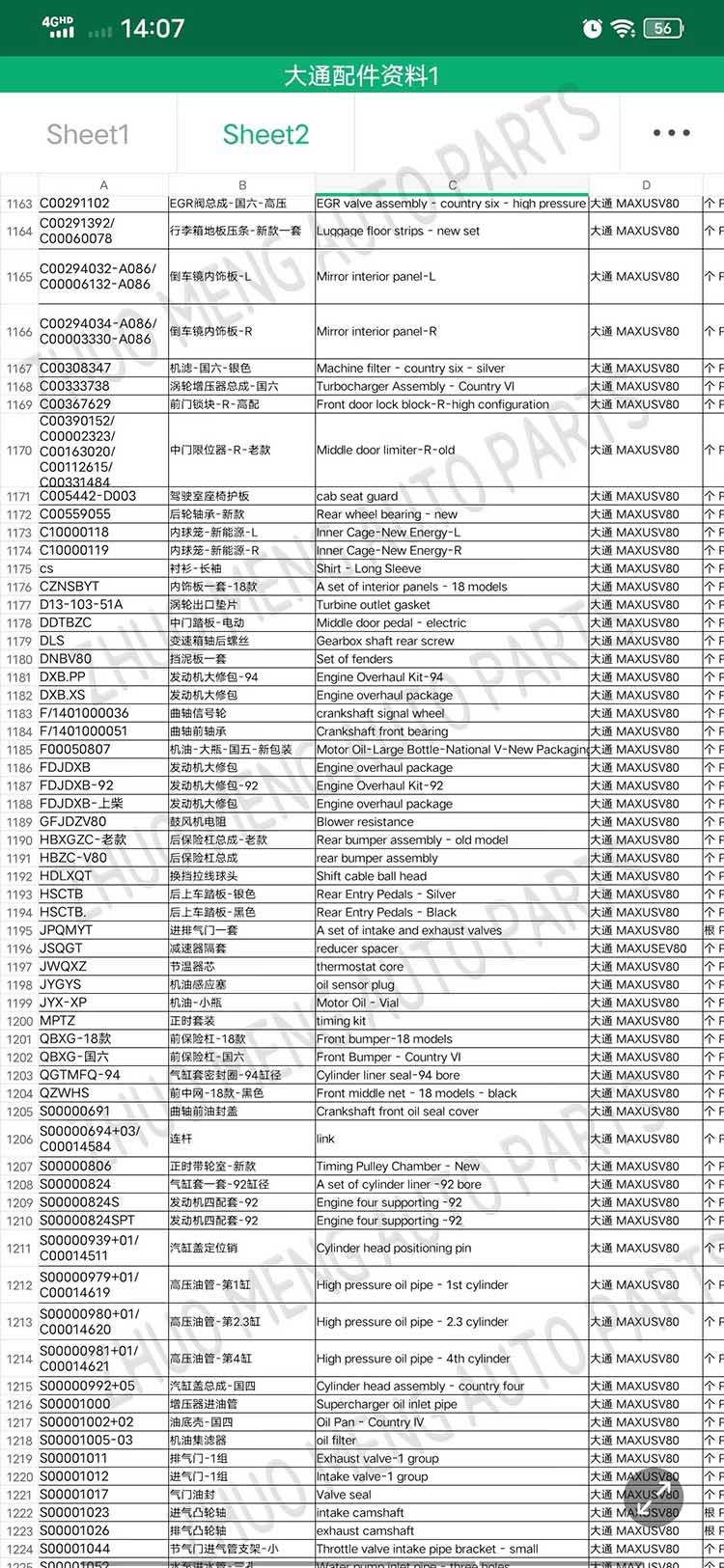

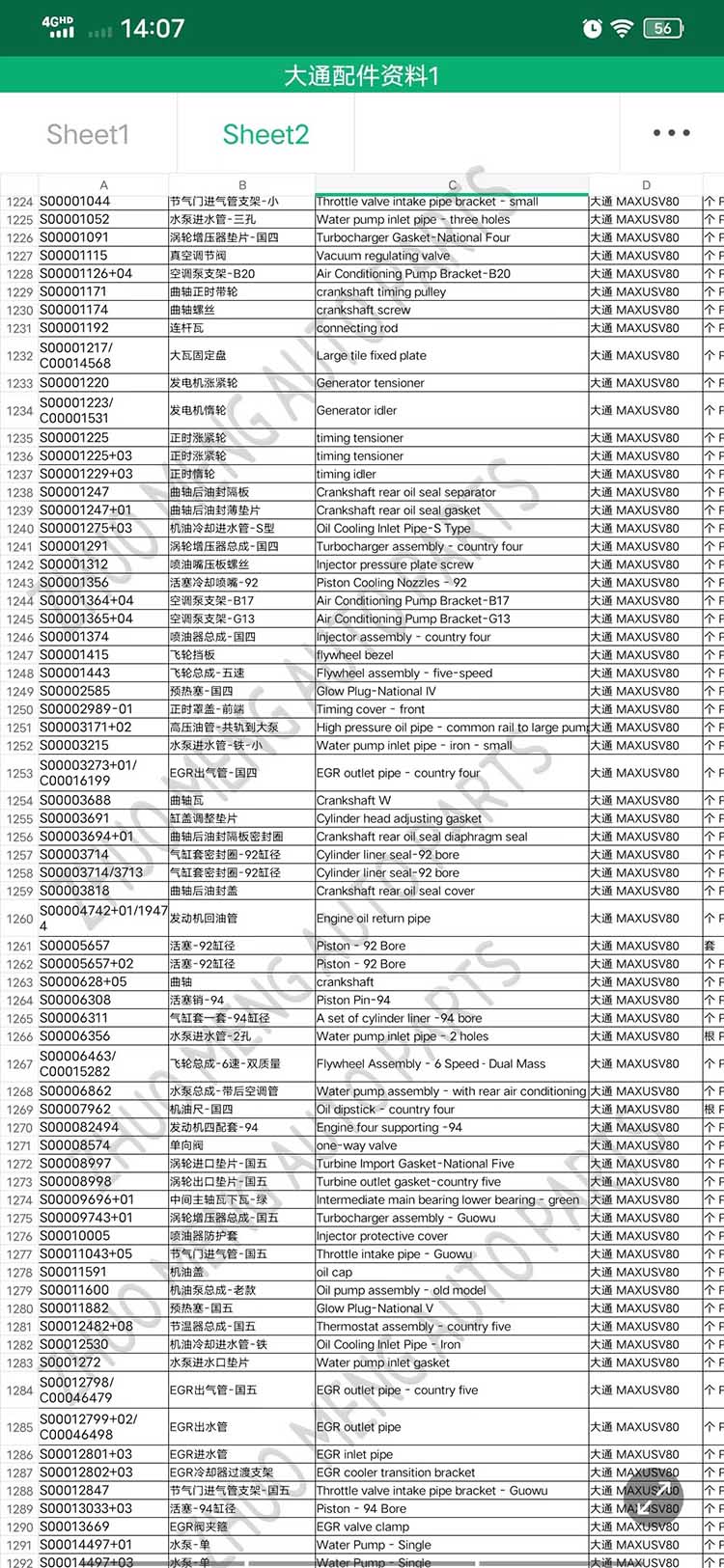

Products catalog

Related products

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Manufacturing Companies for Mgrx5 Ev Auto Parts Wholesale - wholesale supplier SAIC MAXUS V80 Transmission fifth gear – 5 speed C00013867 – Zhuomeng , The product will supply to all over the world, such as: luzern, Barbados, Canada, We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.