Factory supplied Maxus Front Bumper - SAIC MAXUS V80 C0006106 Air Conditioning Pipe – Evaporator to Compressor – Zhuomeng

Factory supplied Maxus Front Bumper - SAIC MAXUS V80 C0006106 Air Conditioning Pipe – Evaporator to Compressor – Zhuomeng Detail:

Products information

| Products name | Air Conditioning Pipe – Evaporator to Compressor |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C0006106 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Cool system |

Products knowledge

The automotive air-conditioning compressor is the heart of the automotive air-conditioning refrigeration system and plays the role of compressing and transporting refrigerant vapor. There are two types of compressors: non-variable displacement and variable displacement. According to different working principles, air conditioning compressors can be divided into fixed displacement compressors and variable displacement compressors.

According to different working methods, compressors can generally be divided into reciprocating and rotary types. Common reciprocating compressors include crankshaft connecting rod type and axial piston type, and common rotary compressors include rotary vane type and scroll type.

The automotive air-conditioning compressor is the heart of the automotive air-conditioning refrigeration system and plays the role of compressing and transporting refrigerant vapor.

Classification

Compressors are divided into two types: non-variable displacement and variable displacement.

Air-conditioning compressors are generally divided into reciprocating and rotary types according to their internal working methods.

Working principle classification editing broadcast

According to different working principles, air conditioning compressors can be divided into fixed displacement compressors and variable displacement compressors.

Fixed displacement compressor

The displacement of the fixed-displacement compressor increases proportionally with the increase of the engine speed. It cannot automatically change the power output according to the cooling demand, and has a relatively large impact on the engine fuel consumption. Its control generally collects the temperature signal of the air outlet of the evaporator. When the temperature reaches the set temperature, the electromagnetic clutch of the compressor is released and the compressor stops working. When the temperature rises, the electromagnetic clutch is engaged and the compressor starts to work. The fixed displacement compressor is also controlled by the pressure of the air conditioning system. When the pressure in the pipeline is too high, the compressor stops working.

Variable displacement air conditioner compressor

The variable displacement compressor can automatically adjust the power output according to the set temperature. The air-conditioning control system does not collect the temperature signal of the air outlet of the evaporator, but controls the compression ratio of the compressor according to the change signal of the pressure in the air-conditioning pipeline to automatically adjust the air outlet temperature. In the whole process of refrigeration, the compressor is always working, and the adjustment of the refrigeration intensity is completely controlled by the pressure regulating valve installed inside the compressor. When the pressure at the high-pressure end of the air-conditioning pipeline is too high, the pressure regulating valve shortens the piston stroke in the compressor to reduce the compression ratio, which will reduce the refrigeration intensity. When the pressure at the high pressure end drops to a certain level and the pressure at the low pressure end rises to a certain level, the pressure regulating valve increases the piston stroke to improve the refrigeration intensity.

Classification of work style

According to different working methods, compressors can generally be divided into reciprocating and rotary types. Common reciprocating compressors include crankshaft connecting rod type and axial piston type, and common rotary compressors include rotary vane type and scroll type.

Crankshaft connecting rod compressor

The working process of this compressor can be divided into four, namely compression, exhaust, expansion, suction. When the crankshaft rotates, the connecting rod drives the piston to reciprocate, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston changes periodically, thus compressing and transporting the refrigerant in the refrigeration system. The crankshaft connecting rod compressor is the first generation compressor. It is widely used, has mature manufacturing technology, simple structure, low requirements on processing materials and processing technology, and relatively low cost. It has strong adaptability, can adapt to a wide pressure range and refrigeration capacity requirements, and has strong maintainability.

However, the crankshaft connecting rod compressor also has some obvious shortcomings, such as the inability to achieve high speed, the machine is large and heavy, and it is not easy to achieve light weight. The exhaust is discontinuous, the airflow is prone to fluctuations, and there is a large vibration during operation.

Due to the above characteristics of crankshaft-connecting-rod compressors, few small-displacement compressors have adopted this structure. At present, crankshaft-connecting-rod compressors are mostly used in large-displacement air conditioning systems for passenger cars and trucks.

Axial Piston Compressor

Axial piston compressors can be called second-generation compressors, and the common ones are rocker-plate or swash-plate compressors, which are the mainstream products in automotive air-conditioning compressors. The main components of a swash plate compressor are the main shaft and the swash plate. The cylinders are circumferentially arranged with the main shaft of the compressor as the center, and the movement direction of the piston is parallel to the main shaft of the compressor. The pistons of most swash plate compressors are made as double-headed pistons, such as axial 6-cylinder compressors, 3 cylinders are at the front of the compressor, and the other 3 cylinders are at the rear of the compressor. The double-headed pistons slide in tandem in the opposite cylinders. When one end of the piston compresses the refrigerant vapor in the front cylinder, the other end of the piston inhales the refrigerant vapor in the rear cylinder. Each cylinder is equipped with high and low pressure air valves, and another high pressure pipe is used to connect the front and rear high pressure chambers. The inclined plate is fixed with the main shaft of the compressor, the edge of the inclined plate is assembled in the groove in the middle of the piston, and the piston groove and the edge of the inclined plate are supported by steel ball bearings. When the main shaft rotates, the swash plate also rotates, and the edge of the swash plate pushes the piston to reciprocate axially. If the swash plate rotates once, the front and rear two pistons each complete a cycle of compression, exhaust, expansion, and suction, which is equivalent to the work of two cylinders. If it is an axial 6-cylinder compressor, 3 cylinders and 3 double-headed pistons are evenly distributed on the section of the cylinder block. When the main shaft rotates once, it is equivalent to the effect of 6 cylinders.

The swash plate compressor is relatively easy to achieve miniaturization and light weight, and can achieve high-speed operation. It has compact structure, high efficiency and reliable performance. After realizing variable displacement control, it is widely used in automobile air conditioners.

Rotary Vane Compressor

There are two types of cylinder shapes for rotary vane compressors: circular and oval. In a circular cylinder, the main shaft of the rotor has an eccentric distance from the center of the cylinder, so that the rotor is closely attached between the suction and exhaust holes on the inner surface of the cylinder. In an elliptical cylinder, the main axis of the rotor and the center of the ellipse coincide. The blades on the rotor divide the cylinder into several spaces. When the main shaft drives the rotor to rotate once, the volume of these spaces changes continuously, and the refrigerant vapor also changes in volume and temperature in these spaces. Rotary vane compressors do not have a suction valve because the vanes do the job of sucking in and compressing the refrigerant. If there are 2 blades, there are 2 exhaust processes in one rotation of the main shaft. The more blades, the smaller the compressor discharge fluctuations.

As a third-generation compressor, because the volume and weight of the rotary vane compressor can be made small, it is easy to arrange in a narrow engine compartment, coupled with the advantages of low noise and vibration, and high volumetric efficiency, it is also used in automotive air conditioning systems. got some application. However, the rotary vane compressor has high requirements on machining accuracy and high manufacturing cost.

scroll compressor

Such compressors may be referred to as 4th generation compressors. The structure of scroll compressors is mainly divided into two types: dynamic and static type and double revolution type. At present, the dynamic and static type is the most common application. Its working parts are mainly composed of a dynamic turbine and a static turbine. The structures of the dynamic and static turbines are very similar, and they are both composed of an end plate and an involute spiral tooth extending from the end plate , the two are eccentrically arranged and the difference is 180°, the static turbine is stationary, and the moving turbine is eccentrically rotated and translated by the crankshaft under the constraint of a special anti-rotation mechanism, that is, there is no rotation, only revolution. Scroll compressors have many advantages. For example, the compressor is small in size and light in weight, and the eccentric shaft that drives the motion of the turbine can rotate at high speed. Because there is no suction valve and discharge valve, the scroll compressor operates reliably, and it is easy to realize variable speed movement and variable displacement technology. Multiple compression chambers work at the same time, the gas pressure difference between adjacent compression chambers is small, the gas leakage is small, and the volumetric efficiency is high. Scroll compressors have become more and more widely used in the field of small refrigeration due to their advantages of compact structure, high efficiency and energy saving, low vibration and low noise, and working reliability, and thus become one of the main directions of compressor technology development.

Common malfunctions

As a high-speed rotating working part, the air conditioner compressor has a high probability of failure. Common faults are abnormal noise, leakage and non-working.

(1) Abnormal noise There are many reasons for the abnormal noise of the compressor. For example, the electromagnetic clutch of the compressor is damaged, or the inside of the compressor is severely worn, etc., which can cause abnormal noise.

①The electromagnetic clutch of the compressor is a common place where abnormal noise occurs. The compressor often runs from low speed to high speed under high load, so the requirements for the electromagnetic clutch are very high, and the installation position of the electromagnetic clutch is generally close to the ground, and it is often exposed to rainwater and soil. When the bearing in the electromagnetic clutch is damaged abnormal sound occurs.

②In addition to the problem of the electromagnetic clutch itself, the tightness of the compressor drive belt also directly affects the life of the electromagnetic clutch. If the transmission belt is too loose, the electromagnetic clutch is prone to slip; if the transmission belt is too tight, the load on the electromagnetic clutch will increase. When the tightness of the transmission belt is not correct, the compressor will not work at light level, and the compressor will be damaged when it is heavy. When the drive belt is working, if the compressor pulley and the generator pulley are not in the same plane, it will reduce the life of the drive belt or compressor.

③ The repeated suction and closing of the electromagnetic clutch will also cause abnormal noise in the compressor. For example, the power generation of the generator is insufficient, the pressure of the air conditioning system is too high, or the engine load is too large, which will cause the electromagnetic clutch to repeatedly pull in.

④There should be a certain gap between the electromagnetic clutch and the compressor mounting surface. If the gap is too large, the impact will also increase. If the gap is too small, the electromagnetic clutch will interfere with the compressor mounting surface during operation. This is also a common cause of abnormal noise.

⑤ The compressor needs reliable lubrication when working. When the compressor lacks lubricating oil, or the lubricating oil is not used properly, serious abnormal noise will occur inside the compressor, and even cause the compressor to be worn out and scrapped.

(2) Leakage Refrigerant leakage is the most common problem in air conditioning systems. The leaking part of the compressor is usually at the junction of the compressor and the high and low pressure pipes, where it is usually troublesome to check because of the installation location. The internal pressure of the air-conditioning system is very high, and when the refrigerant leaks, the compressor oil will be lost, which will cause the air-conditioning system to not work or the compressor to be poorly lubricated. There are pressure relief protection valves on the air conditioner compressors. The pressure relief protection valves are usually used for one-time use. After the system pressure is too high, the pressure relief protection valve should be replaced in time.

(3) Not working There are many reasons why the air conditioner compressor does not work, usually because of related circuit problems. You can preliminarily check whether the compressor is damaged by directly supplying power to the electromagnetic clutch of the compressor.

Air conditioning maintenance precautions

Safety issues to be aware of when handling refrigerants

(1) Do not handle refrigerant in a closed space or near an open flame;

(2) Protective glasses must be worn;

(3) Avoid liquid refrigerant entering the eyes or splashing on the skin;

(4) Do not point the bottom of the refrigerant tank to people, some refrigerant tanks have emergency venting devices at the bottom;

(5) Do not place the refrigerant tank directly in hot water with a temperature higher than 40°C;

(6) If the liquid refrigerant gets into the eyes or touches the skin, do not rub it, immediately rinse it with plenty of cold water, and immediately go to the hospital to find a doctor for professional treatment, and do not try to deal with it yourself.

OUR EXHIBITION

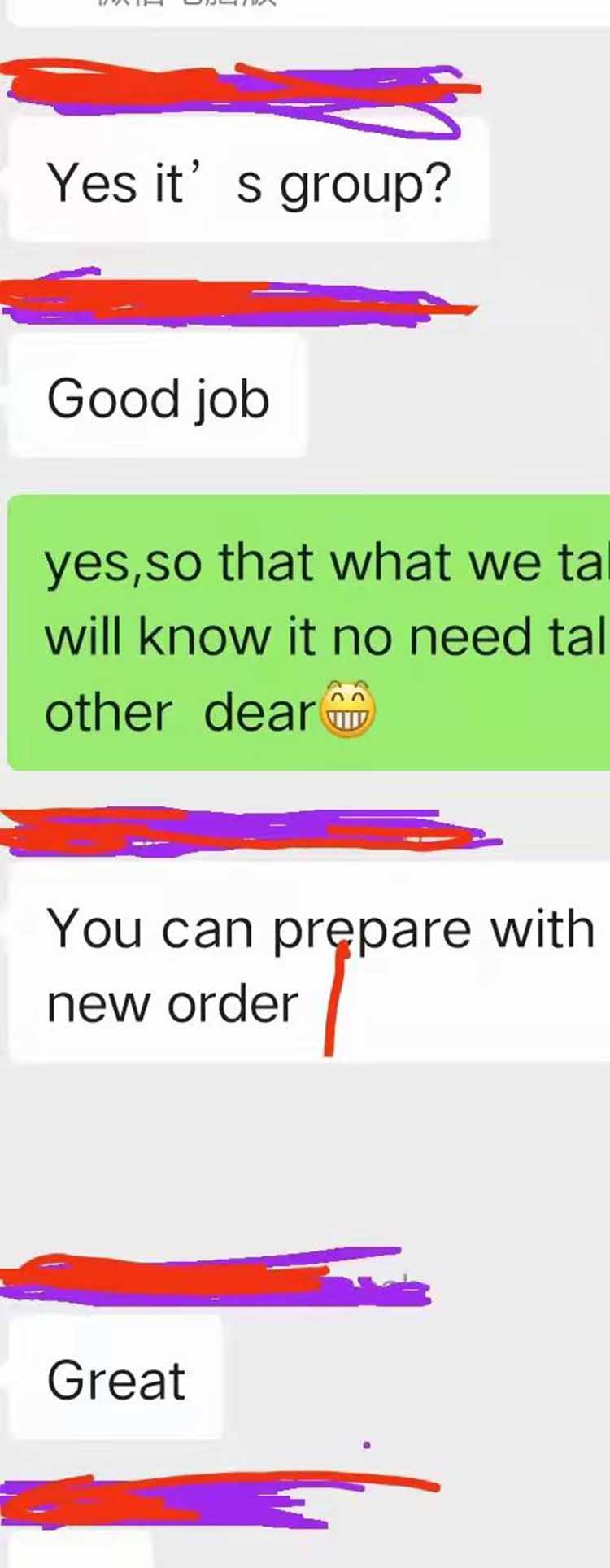

Good Feetback

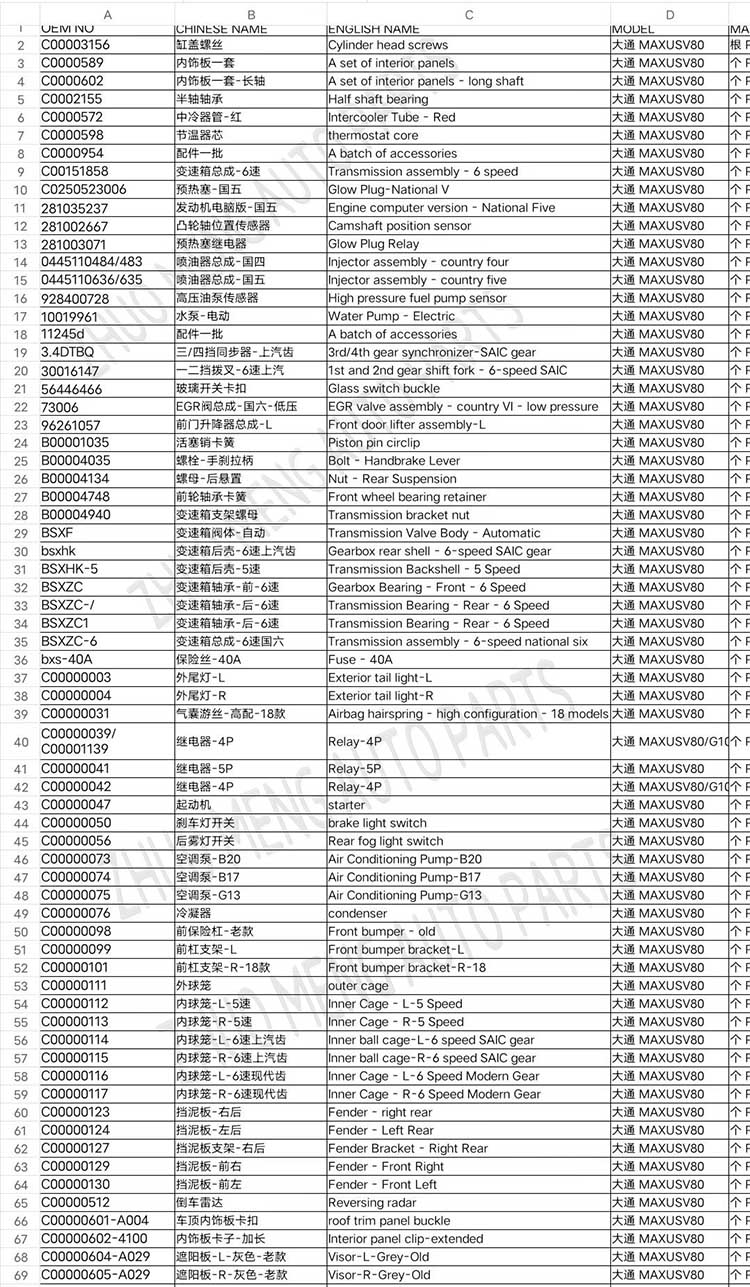

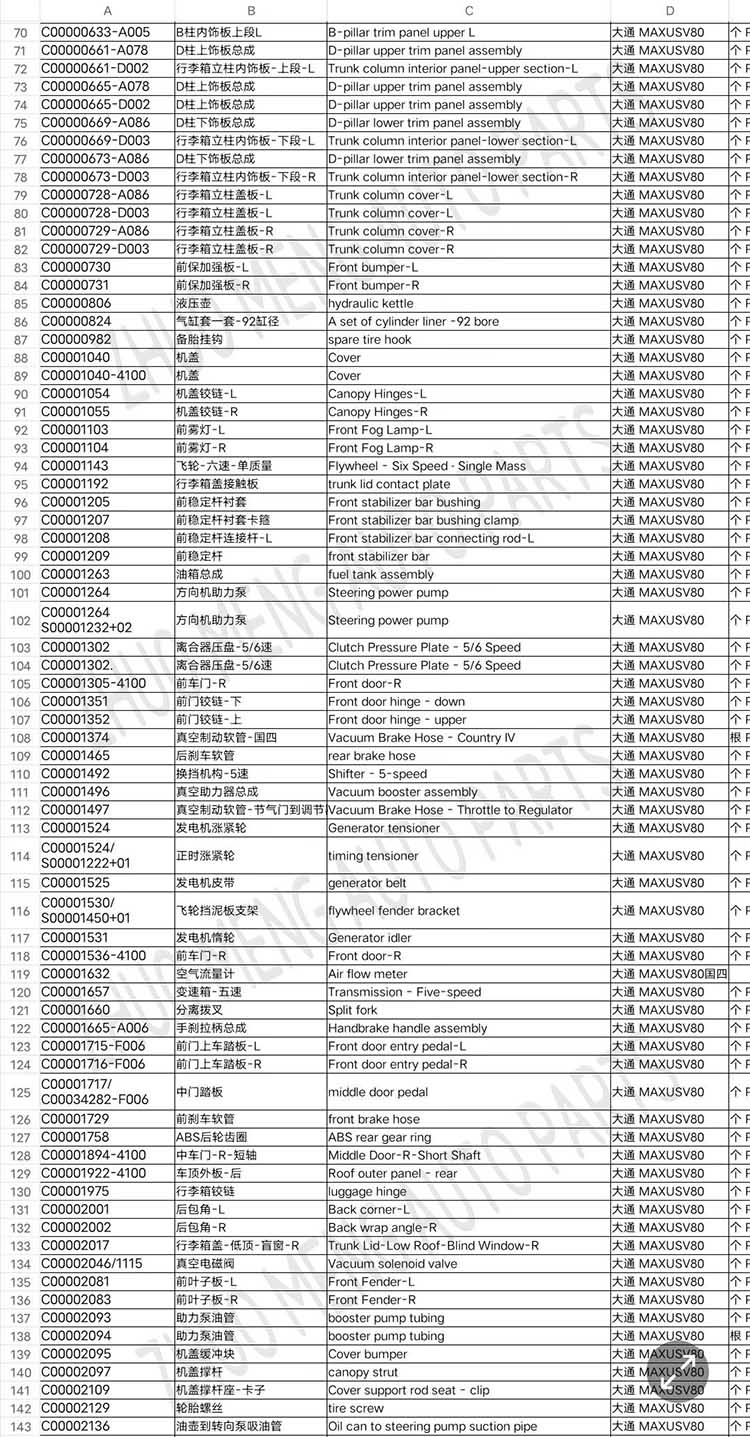

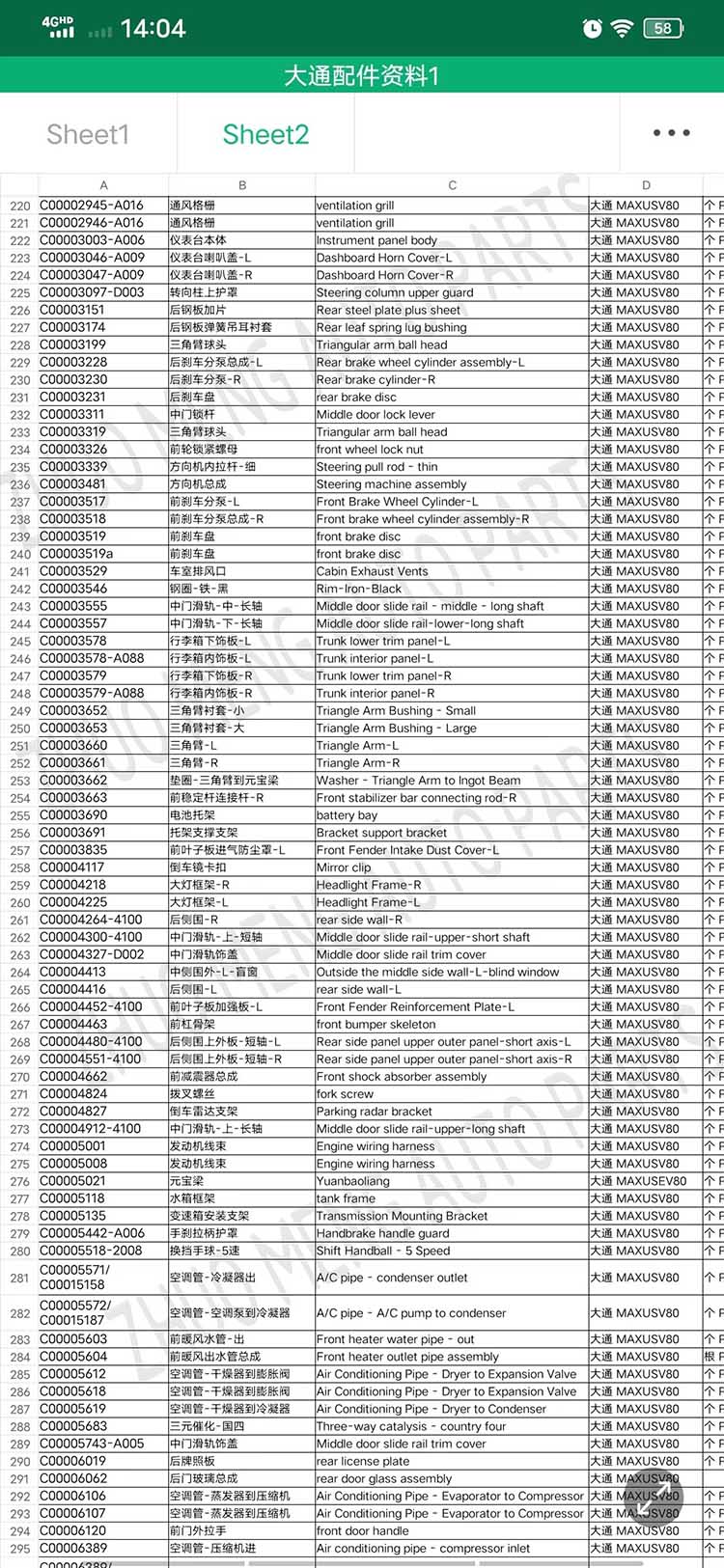

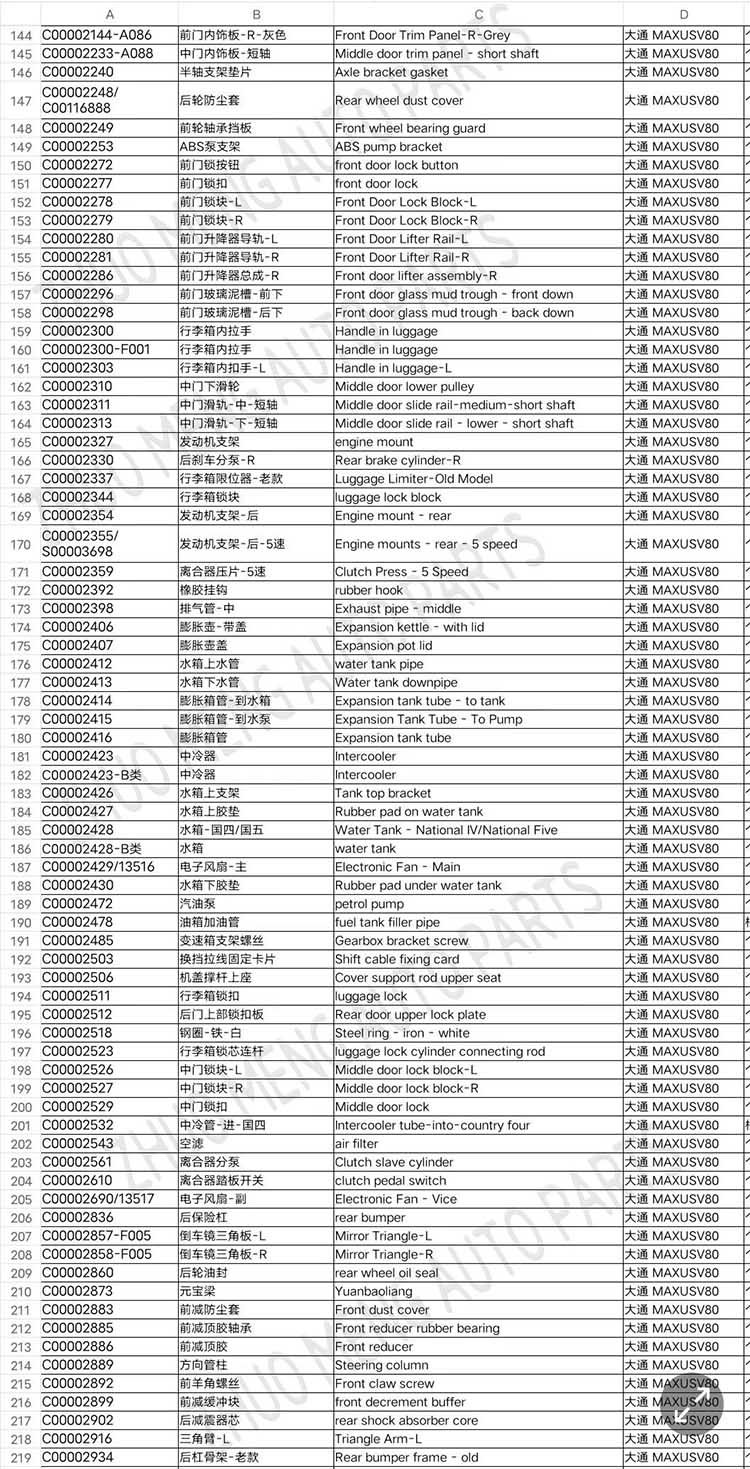

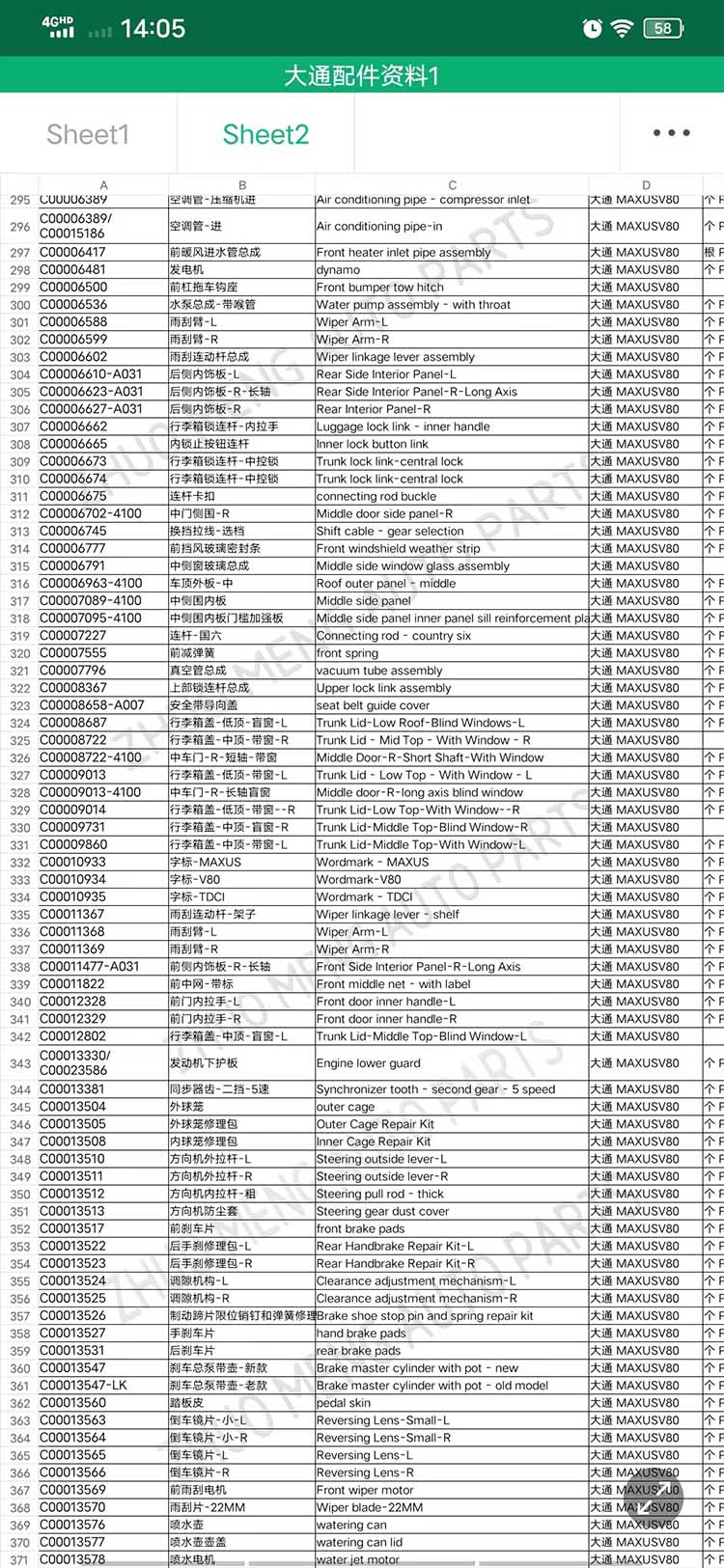

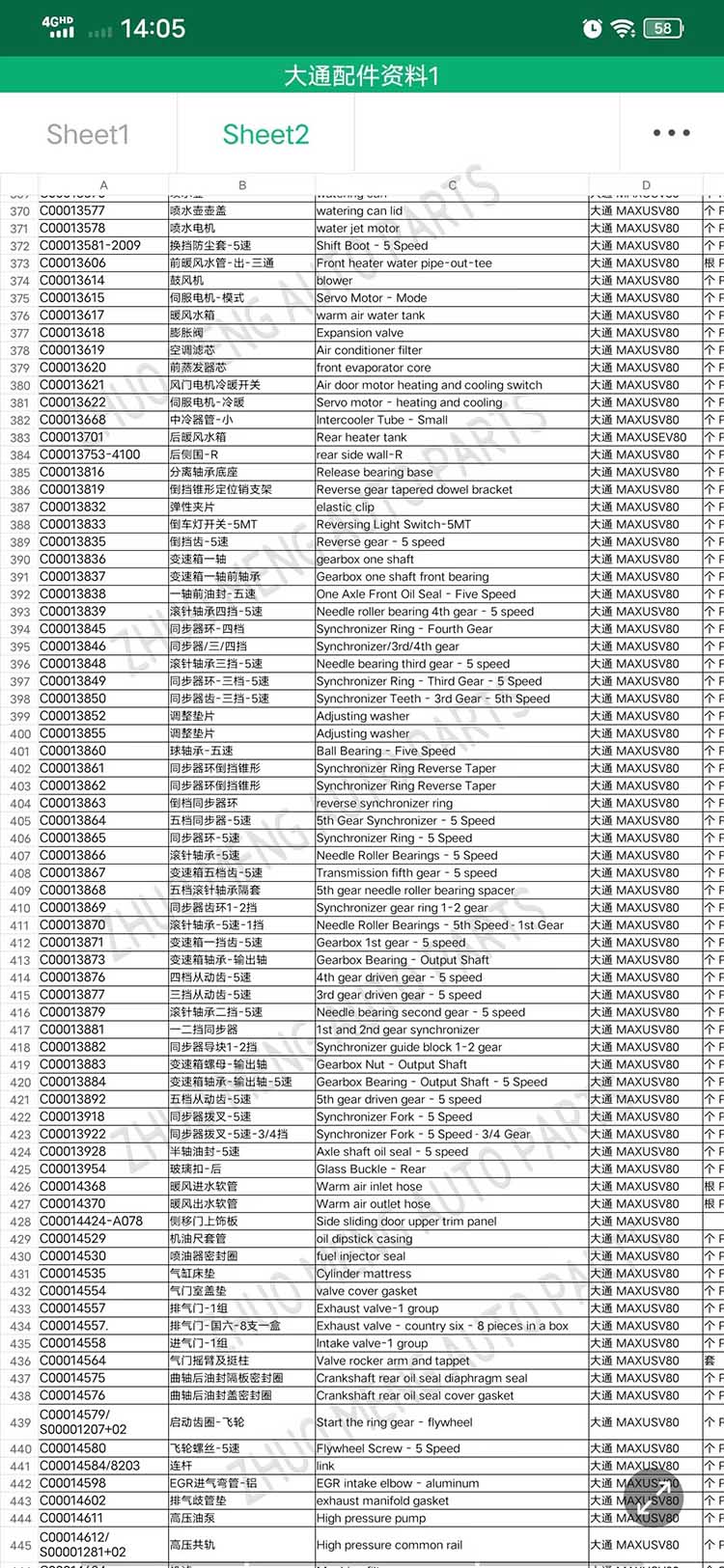

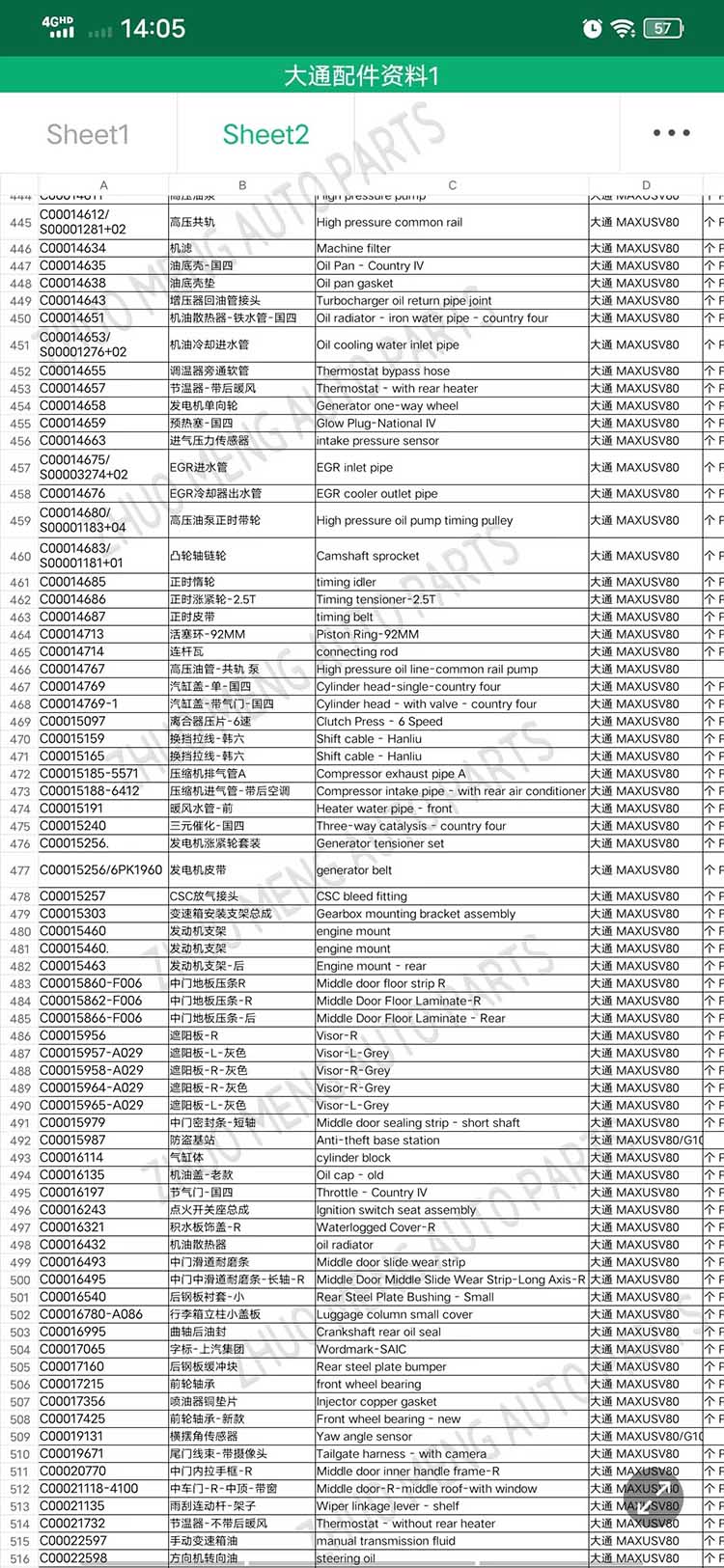

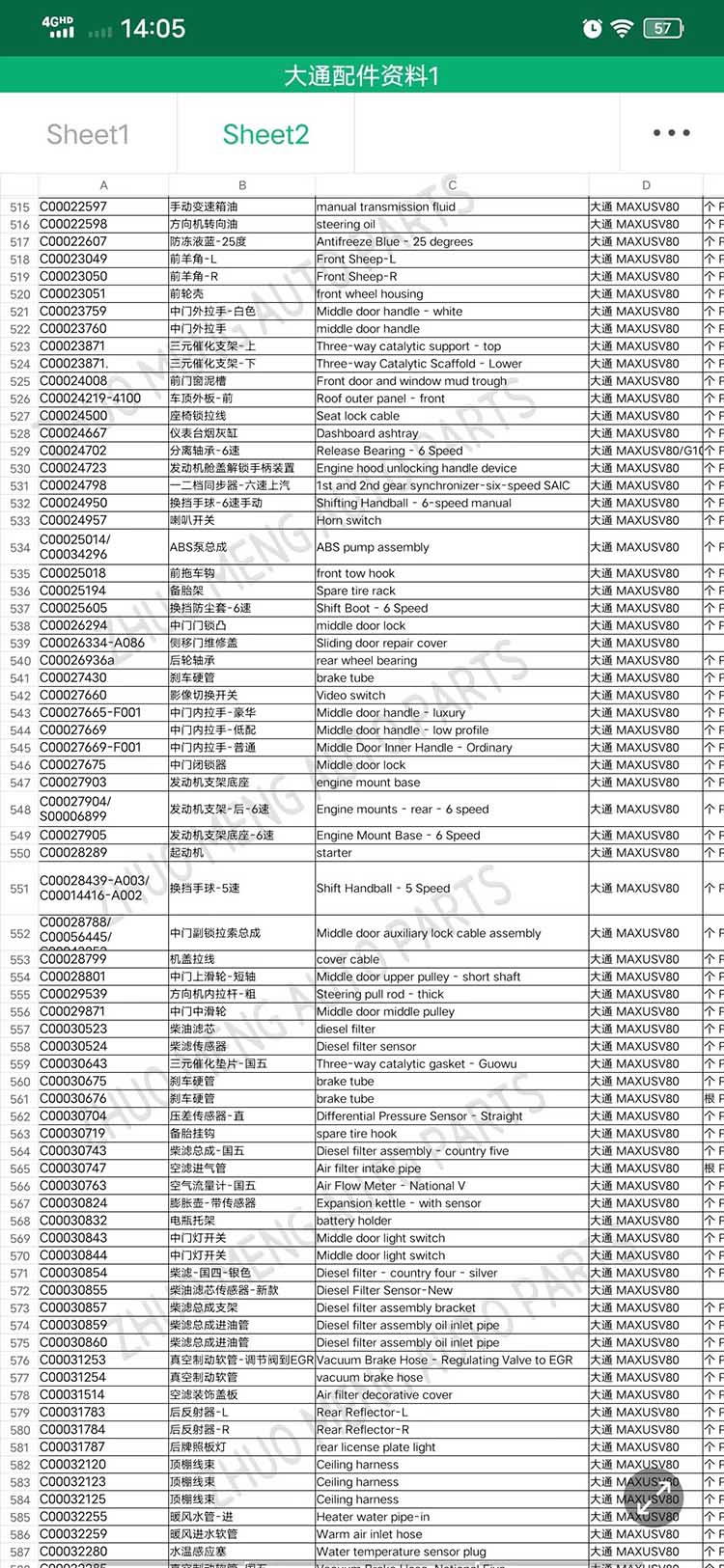

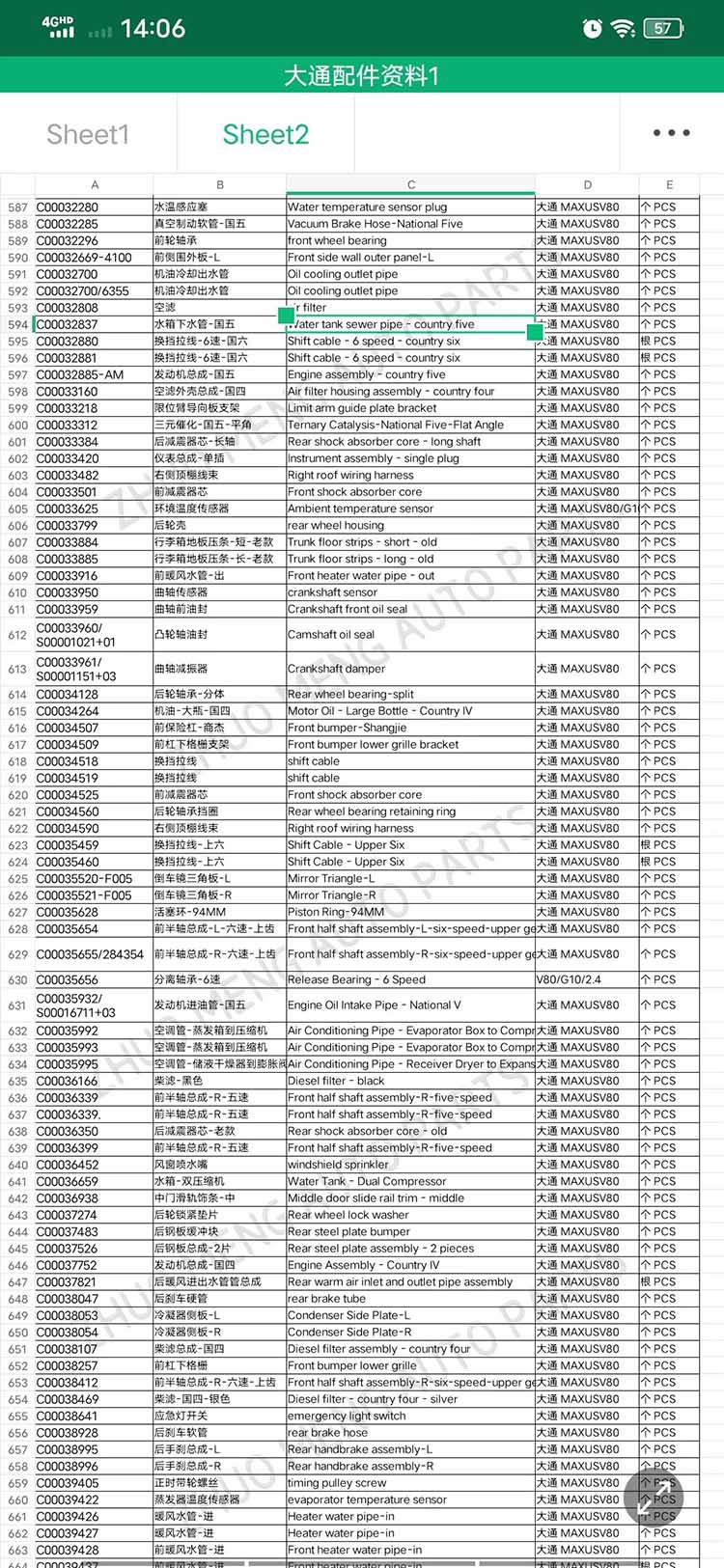

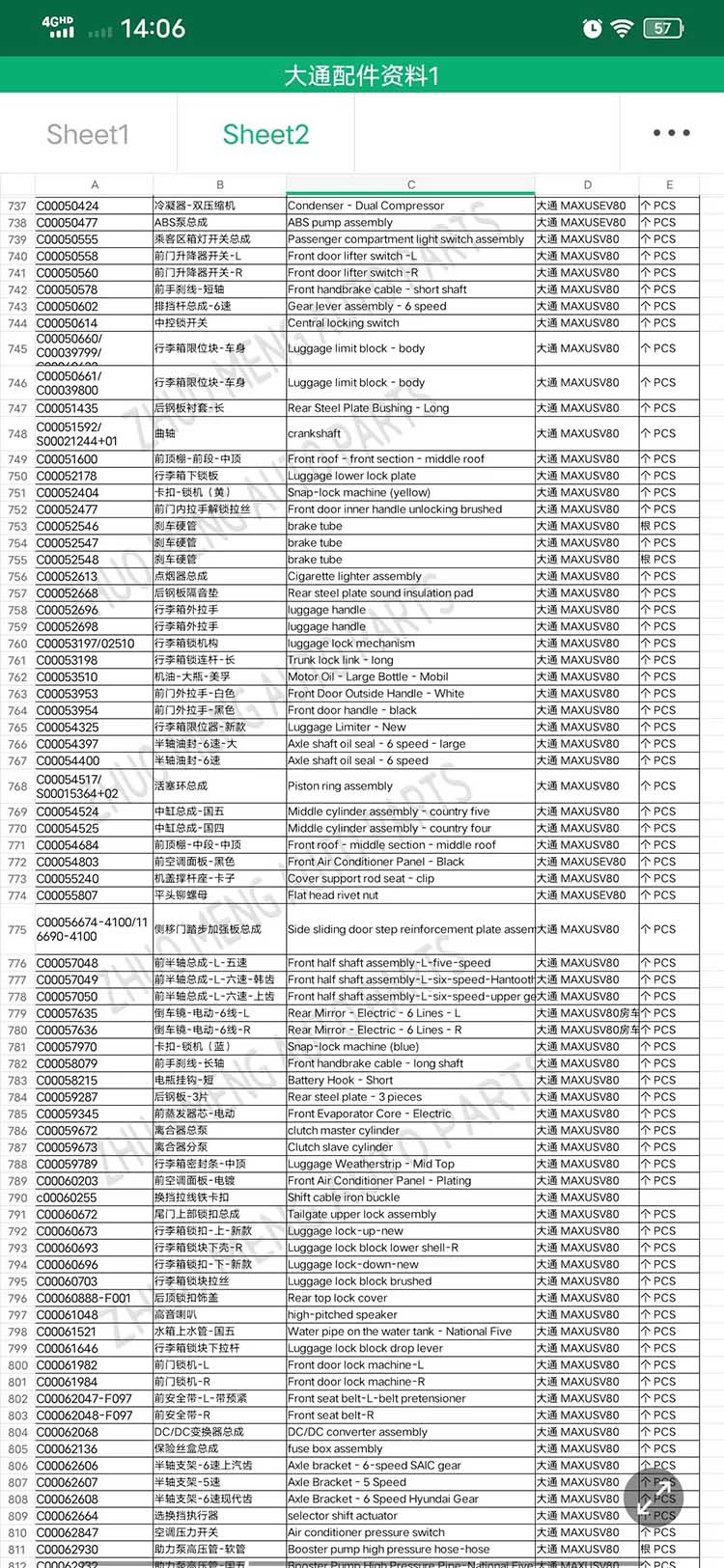

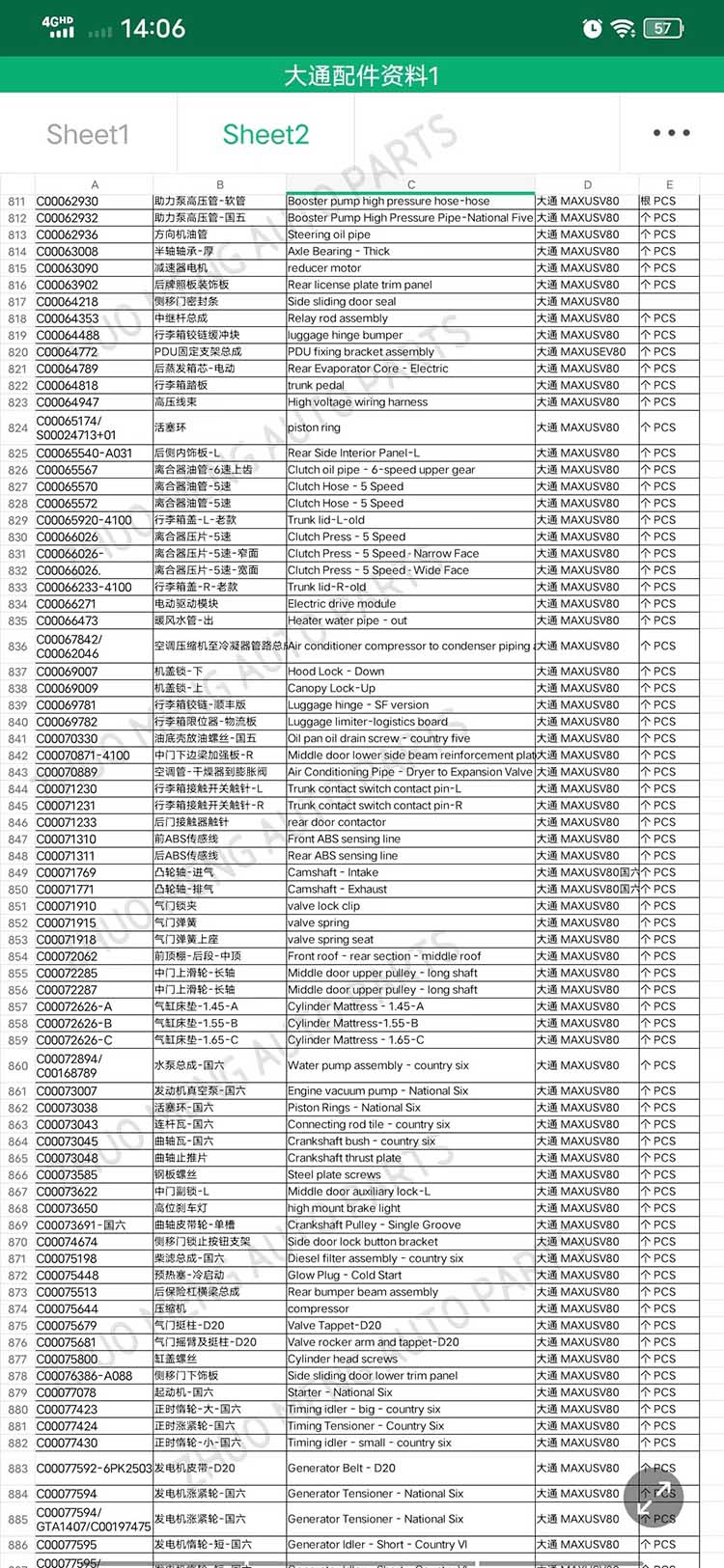

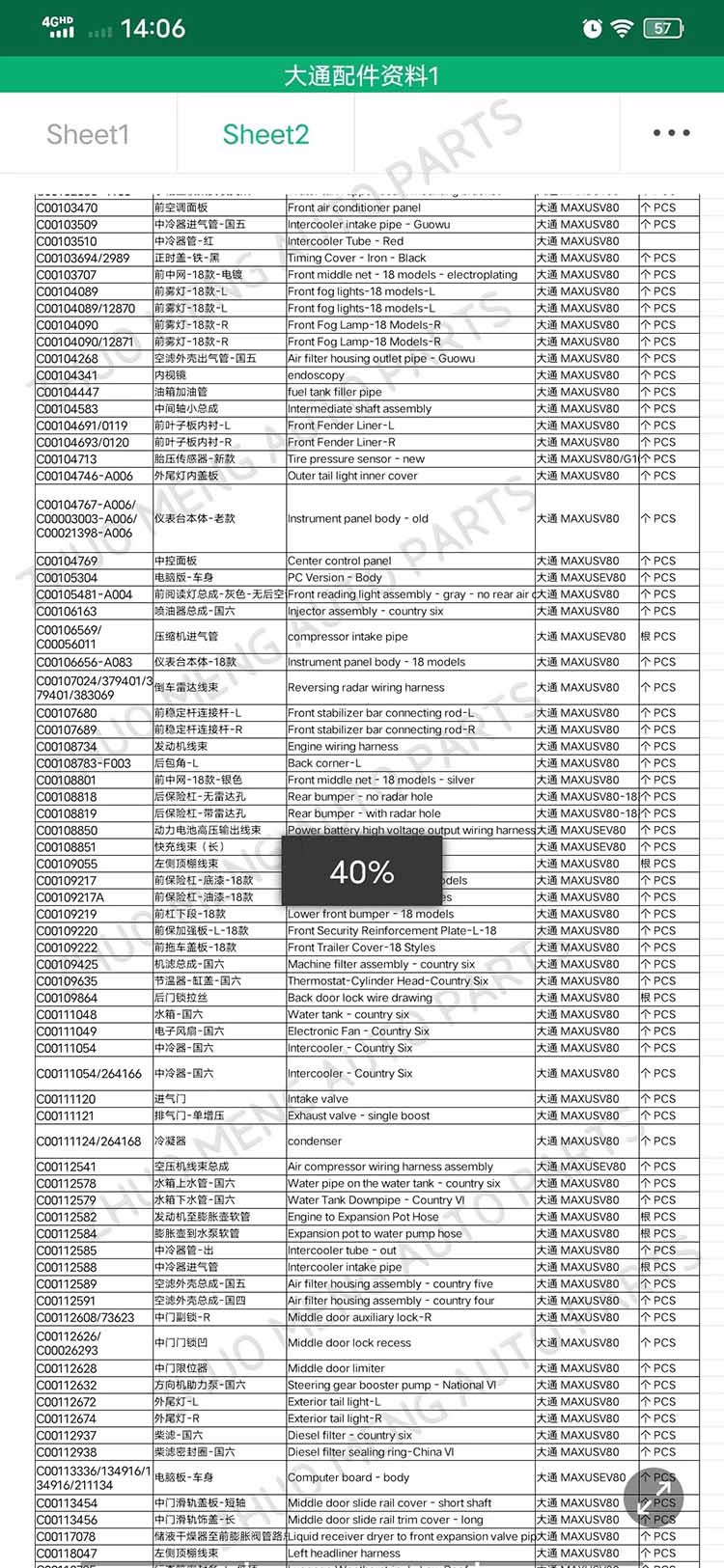

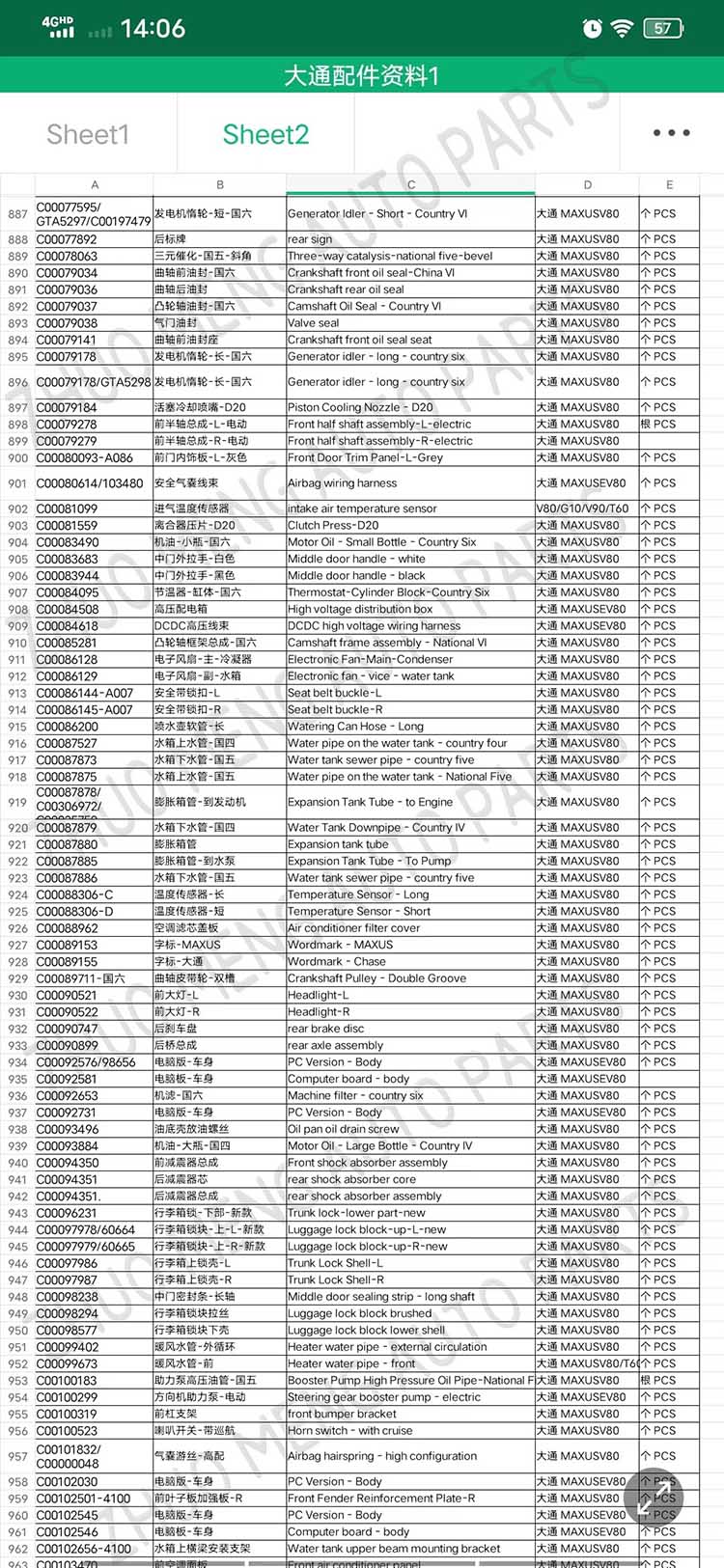

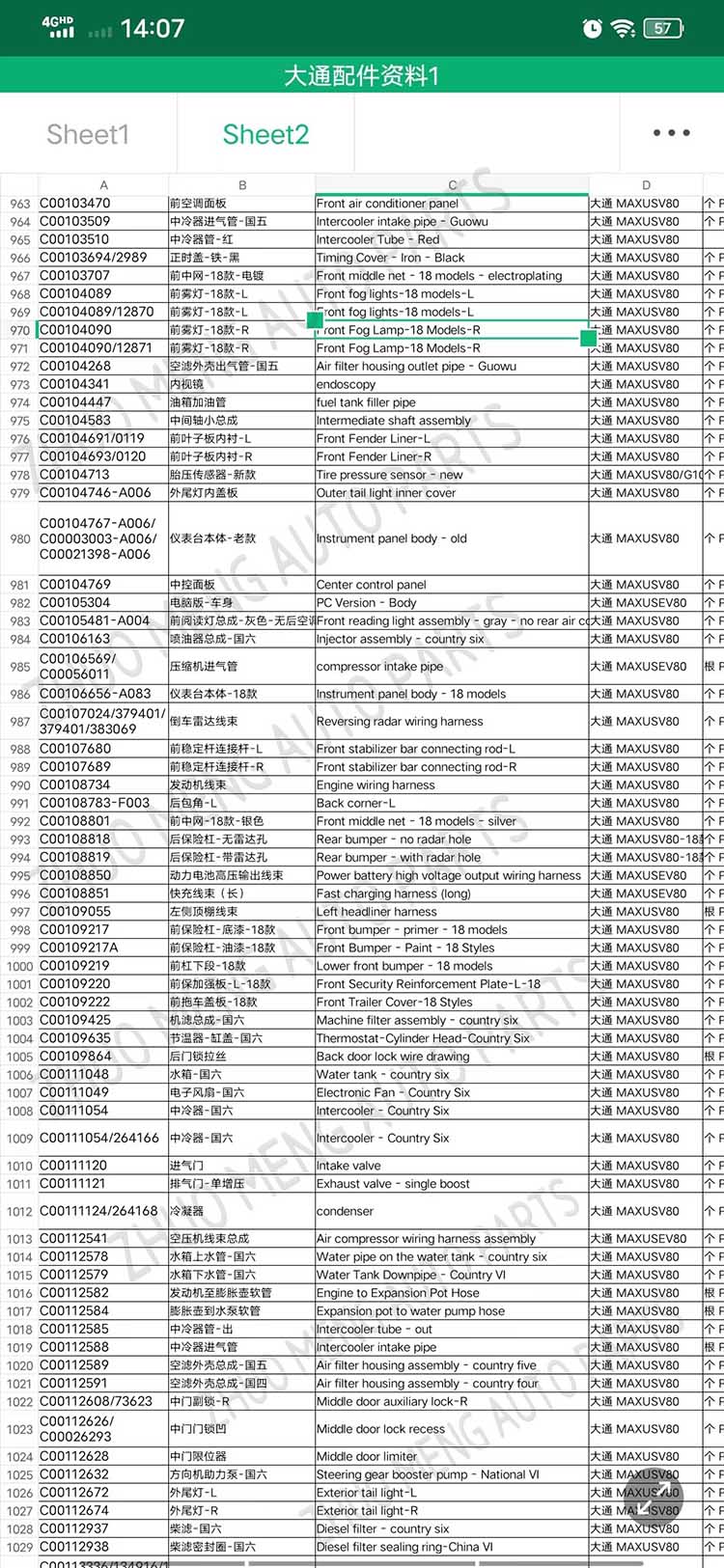

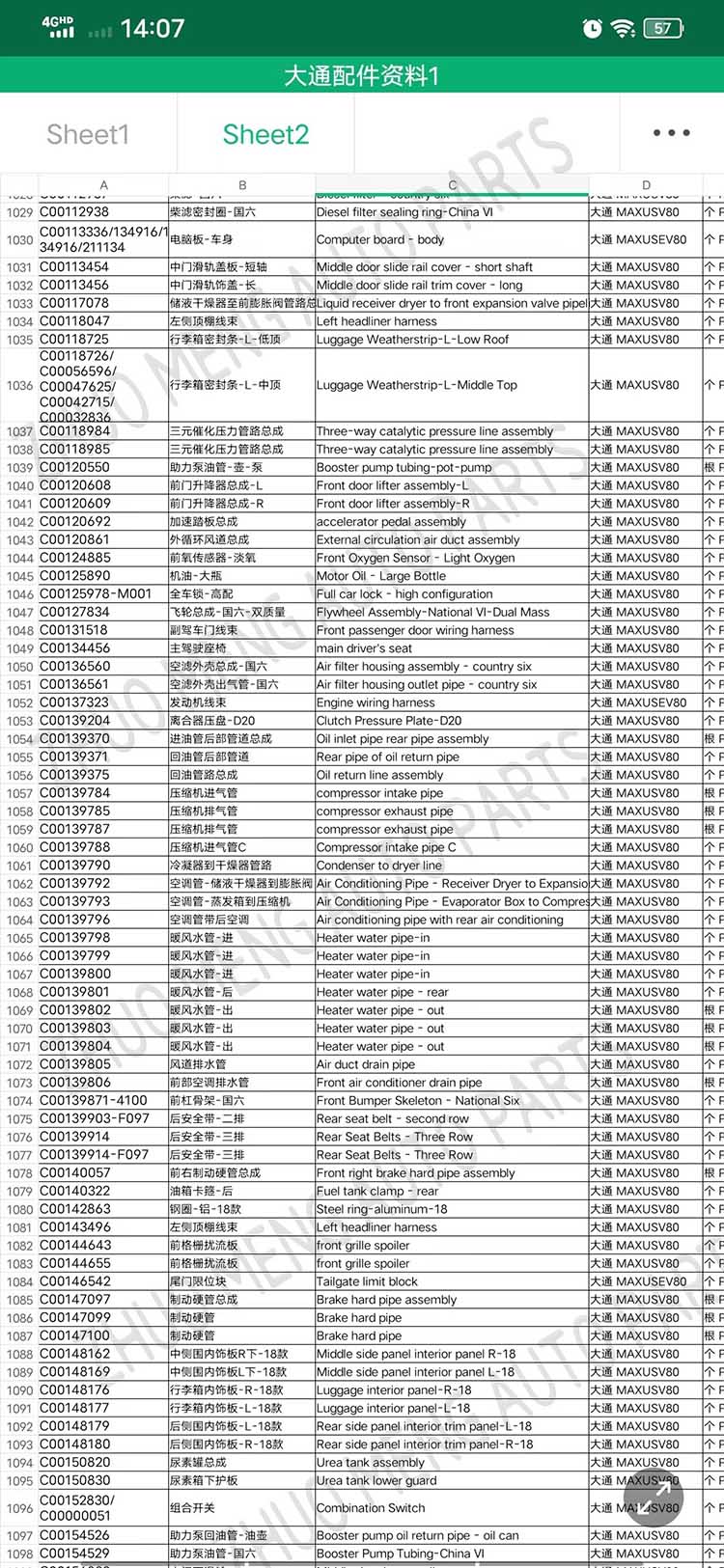

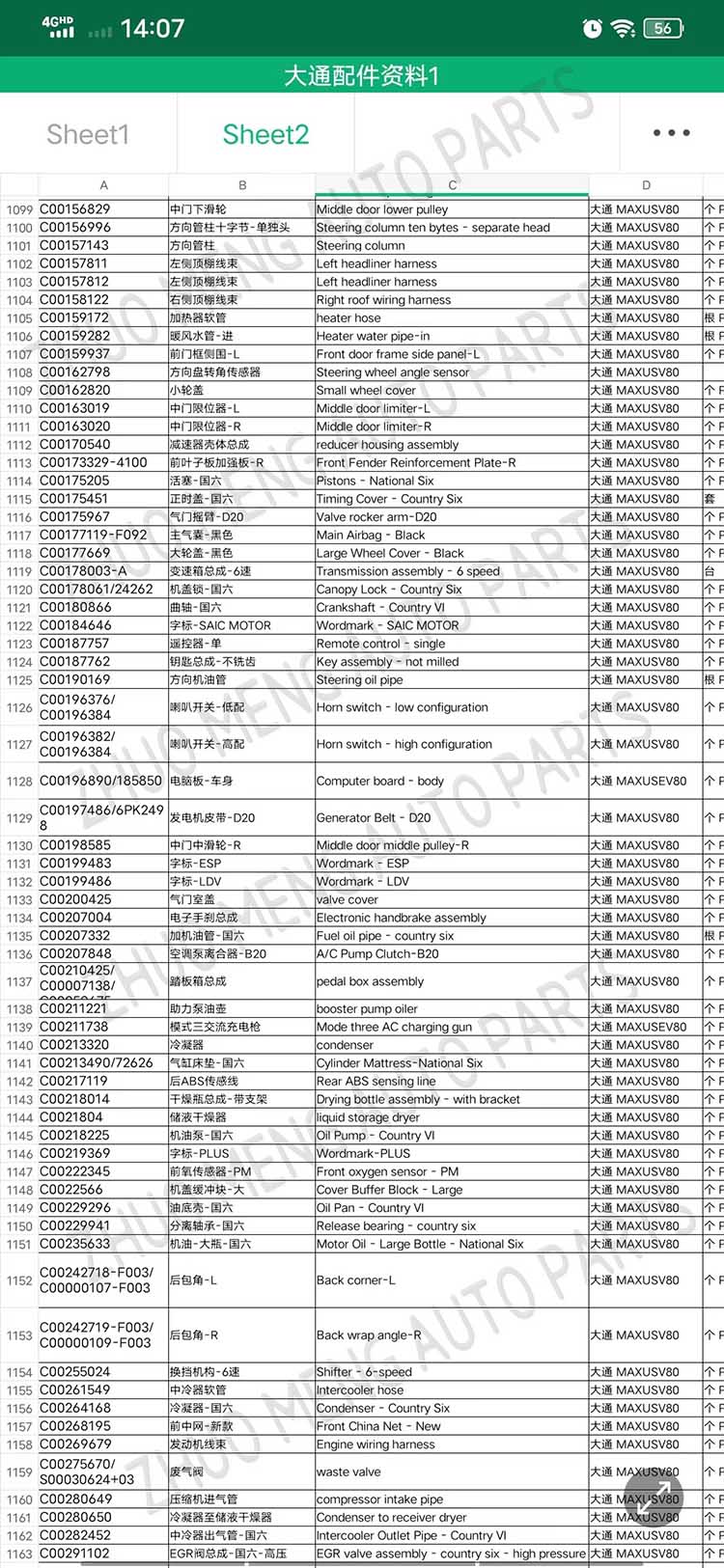

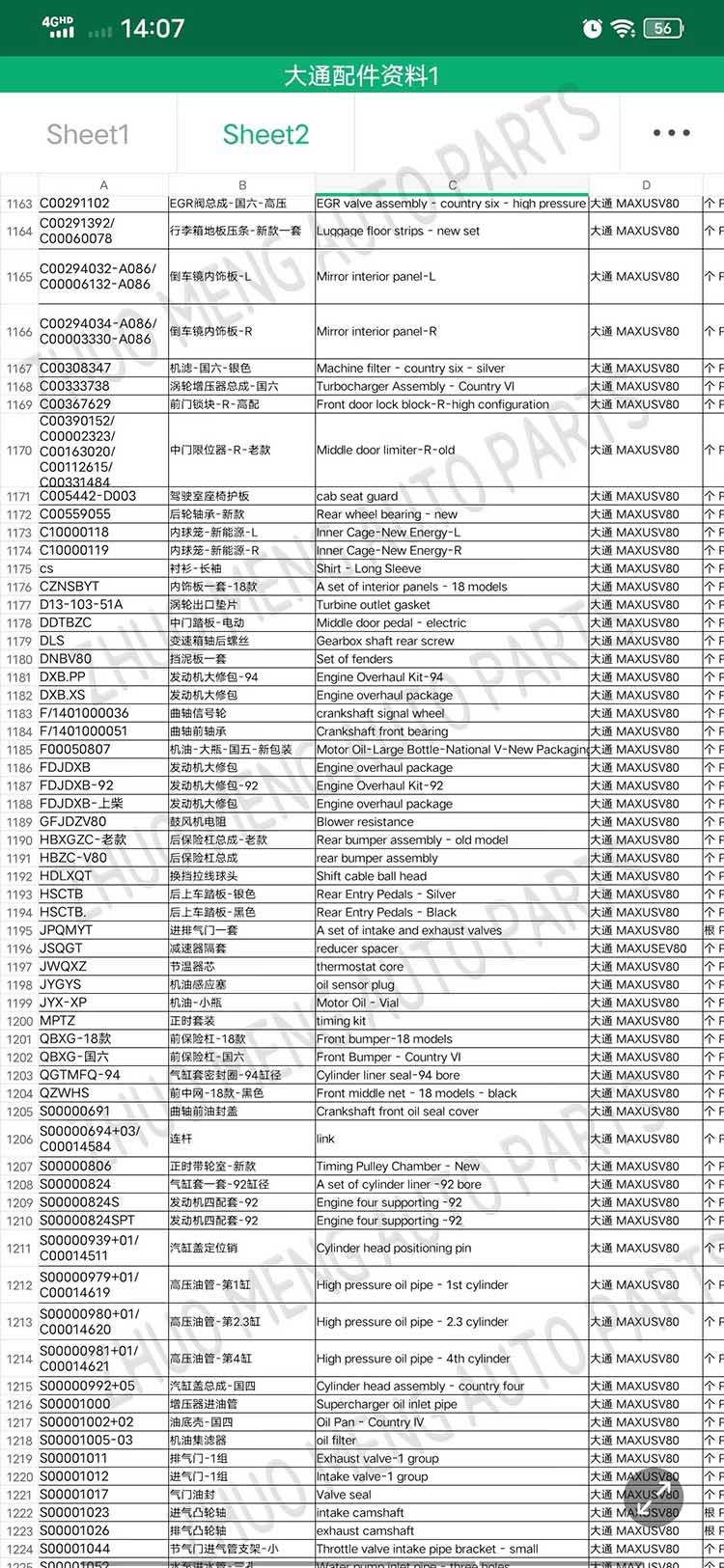

Products catalog

Related products

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Factory supplied Maxus Front Bumper - SAIC MAXUS V80 C0006106 Air Conditioning Pipe – Evaporator to Compressor – Zhuomeng , The product will supply to all over the world, such as: Milan, Bhutan, Manila, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!