Excellent quality Mg Rx5 Parts Wholesale - MG5 Front Shock Absorber Assembly Right – Zhuomeng

Excellent quality Mg Rx5 Parts Wholesale - MG5 Front Shock Absorber Assembly Right – Zhuomeng Detail:

Products Information

| Products Name | Front Shock Absorber Assembly Right |

| Products Application | SAIC MG 5 |

| Products Oem No | 10667179 |

| Org Of Place | MADE IN CHINA |

| Brand | CSSOT / RMOEM / ORG / COPY |

| Lead Time | Stock, If Less 20 Pcs, Normal One Month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application System | Chassis System |

Front Shock Absorber Assembly Right 10667179

Front Shock Absorber Assembly Right 10149409

Rear Shock Absorber Assembly 10331161

Product knowledge

Fault maintenance editing and broadcasting

After determining that there is a problem or failure of the shock absorber, check whether the shock absorber leaks oil or has traces of old oil leakage.

Shock absorber of a vehicle

The oil seal washer and sealing washer are broken and damaged, and the oil storage cylinder cover nut is loose. The oil seal and sealing washer may be damaged and invalid, and the seal shall be replaced with a new one. If the oil leakage still cannot be eliminated, pull out the shock absorber. If you feel hairpin or different weight, further check whether the gap between the piston and the cylinder barrel is too large, whether the piston connecting rod of the shock absorber is bent, and whether there are scratches or pull marks on the surface of the piston connecting rod and the cylinder barrel.

If the shock absorber has no oil leakage, check whether the shock absorber connecting pin, connecting rod, connecting hole, rubber bushing, etc. are damaged, desoldered, cracked or falling off. If the above inspection is normal, further disassemble the shock absorber, check whether the fit gap between the piston and the cylinder barrel is too large, whether the cylinder barrel is strained, whether the valve seal is good, whether the valve disc fits tightly with the valve seat, and whether the extension spring of the shock absorber is too soft or broken. Repair it by grinding or replacing parts according to the situation.

In addition, the shock absorber will make a sound in actual use, which is mainly caused by the collision between the shock absorber and the leaf spring, frame or shaft, the damage or falling off of the rubber pad, the deformation of the shock absorber dust cylinder and insufficient oil. The causes should be found out and repaired.

After the shock absorber is inspected and repaired, the working performance test shall be carried out on a special test bench. When the resistance frequency is 100 ± 1mm, the resistance of its extension stroke and compression stroke shall meet the regulations. For example, the maximum resistance of liberation cal091 in extension stroke is 2156 ~ 2646n, and the maximum resistance of compression stroke is 392 ~ 588n; The maximum resistance of Dongfeng vehicle’s extension stroke is 2450 ~ 3038n, and the maximum resistance of compression stroke is 490 ~ 686n. If there are no test conditions, we can also adopt an empirical method, that is, insert an iron rod into the lower ring of the shock absorber, step on both ends with both feet, hold the upper ring with both hands and pull it back and forth for 2 ~ 4 times. When pulling up, the resistance is very large, and it is not laborious when pressing down. Moreover, the tensile resistance has recovered compared with that before repair, without a sense of emptiness, It indicates that the shock absorber is basically normal

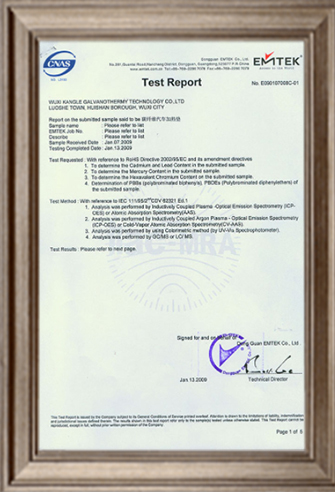

certificate

exhibition

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Excellent quality Mg Rx5 Parts Wholesale - MG5 Front Shock Absorber Assembly Right – Zhuomeng , The product will supply to all over the world, such as: Niger, South Africa, Lyon, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.