Competitive Price for Mg 350 Accessories Wholesale - factory price SAIC MAXUS T60 C00021134 booster pump oil – Zhuomeng

Competitive Price for Mg 350 Accessories Wholesale - factory price SAIC MAXUS T60 C00021134 booster pump oil – Zhuomeng Detail:

Products information

| Products name | booster pump oil |

| Products application | SAIC MAXUS T60 |

| Products OEM NO | C00045835 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Body system |

Products knowledge

booster pump oiler

Auto booster pump refers to a component that contributes to the improvement and stability of automobile performance. It is mainly to assist the driver to adjust the direction of the car. The car has a booster pump, mainly a direction booster pump and a brake vacuum booster pump.

Introduction

Steering assist is mainly to assist the driver to adjust the direction of the car and reduce the intensity of the steering wheel for the driver. Of course, power steering also plays a certain role in the safety and economy of car driving.

Classification

In the existing market, power steering systems can be roughly divided into three categories: mechanical hydraulic power steering systems, electronic hydraulic power steering systems and electric power steering systems.

Mechanical Hydraulic Power Steering System

The mechanical hydraulic power steering system is generally composed of hydraulic pump, oil pipe, pressure flow control valve body, V-type transmission belt, oil storage tank and other components.

No matter whether the car is steered or not, this system has to work, and when the vehicle speed is low in large steering, the hydraulic pump needs to output more power to obtain a relatively large boost. Therefore, resources are wasted to a certain extent. It can be recalled: driving such a car, especially when turning at low speed, feels that the direction is relatively heavy, and the engine is more laborious. Moreover, due to the high pressure of the hydraulic pump, it is easier to damage the power assist system.

In addition, the mechanical hydraulic power steering system consists of a hydraulic pump, pipelines and oil cylinders. In order to maintain the pressure, no matter whether steering assistance is required or not, the system must always be in a working state, and the energy consumption is high, which is also one of the reasons for the consumption of resources.

Generally, more economical cars use mechanical hydraulic power assist systems.

Electro-hydraulic power steering system

Main components: oil storage tank, power steering control unit, electric pump, steering gear, power steering sensor, etc., of which the power steering control unit and the electric pump are an integral structure.

Working principle: The electronic hydraulic steering assist system overcomes the shortcomings of the traditional hydraulic steering assist system. The hydraulic pump it uses is no longer directly driven by the engine belt, but an electric pump, and all its working states are the most ideal states calculated by the electronic control unit according to the vehicle’s driving speed, steering angle and other signals. Simply put, at low speed and large steering, the electronic control unit drives the electronic hydraulic pump to output more power at high speed, so that the driver can steer and save effort; when the car is driving at high speed, the hydraulic control unit drives the electronic hydraulic pump at a lower speed. When running, it saves a part of the engine power without affecting the need for high-speed steering.

Electric Power Steering (EPS)

The full English name is Electronic Power Steering, or EPS for short, which uses the power generated by the electric motor to assist the driver in power steering. The composition of EPS is basically the same for different cars although the structural components are different. Generally, it is composed of torque (steering) sensor, electronic control unit, electric motor, reducer, mechanical steering gear and battery power supply.

Main working principle: When the car is turning, the torque (steering) sensor will “feel” the torque of the steering wheel and the direction to be rotated. These signals will be sent to the electronic control unit through the data bus, and the electronic control unit will be based on the transmission torque, The data signals such as the direction to be rotated send action commands to the motor controller, so that the motor will output a corresponding amount of torque according to specific needs, thereby generating power steering. If it is not turned, the system will not work and will be in a standby (sleep) state waiting to be called. Due to the working characteristics of electric power steering, you will feel that driving such a car, the sense of direction is better, and it is more stable at high speed, which is the saying that the direction does not float. And because it does not work when it is not turning, it also saves energy to some extent. Generally, more high-end cars use such power steering systems.

OUR EXHIBITION

Good Feetback

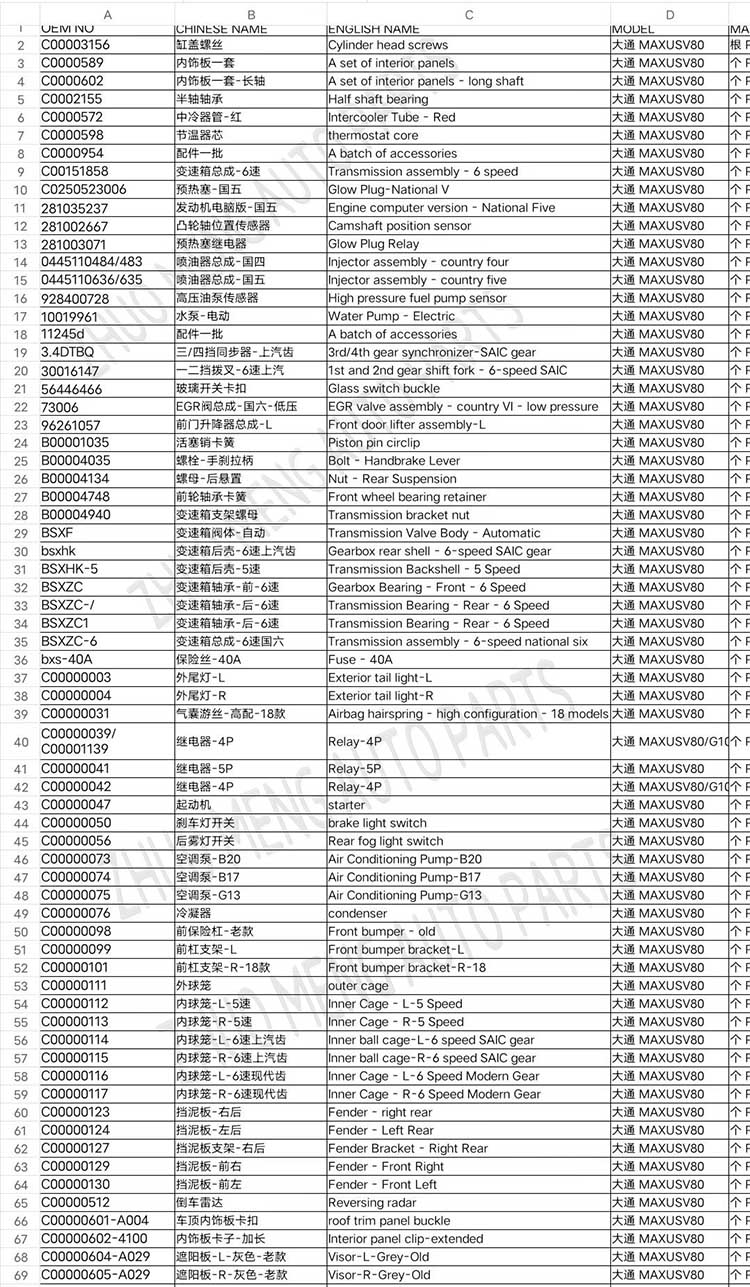

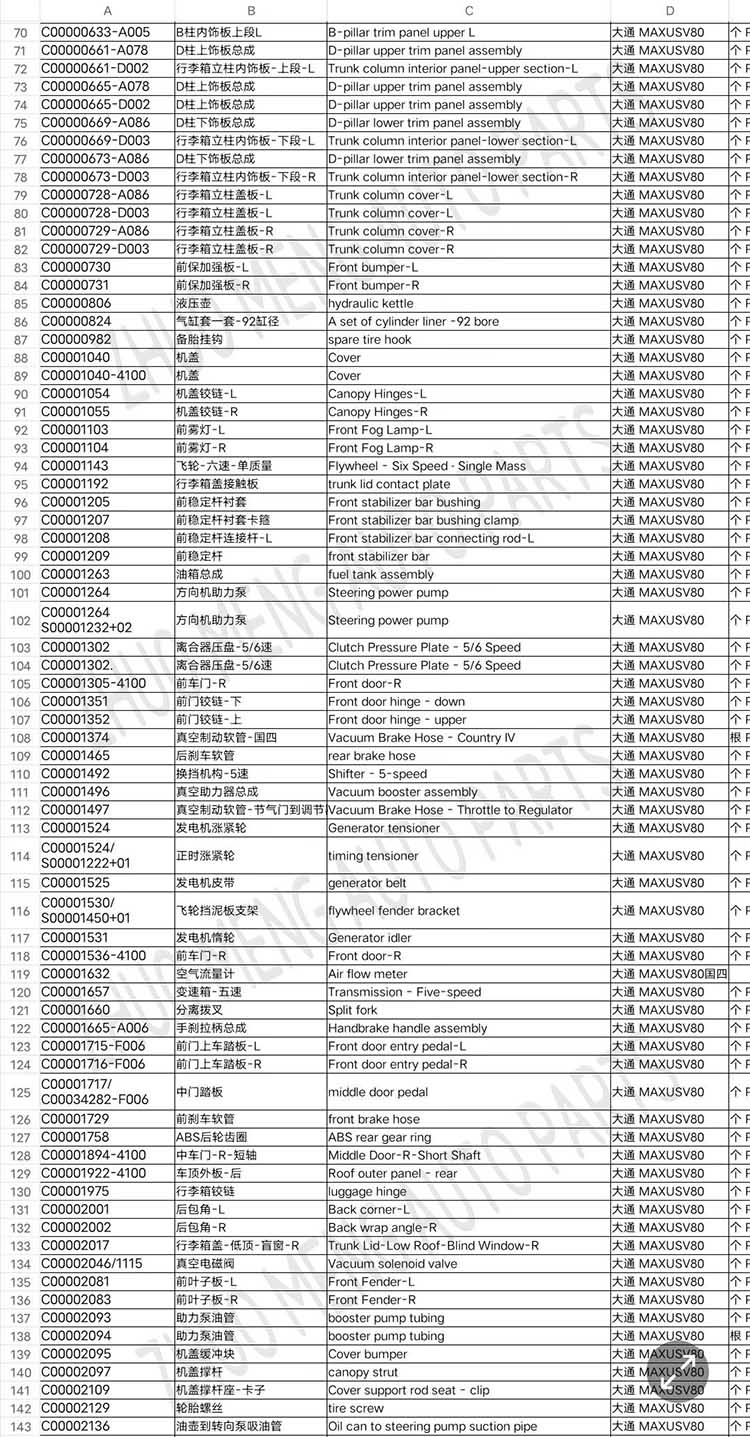

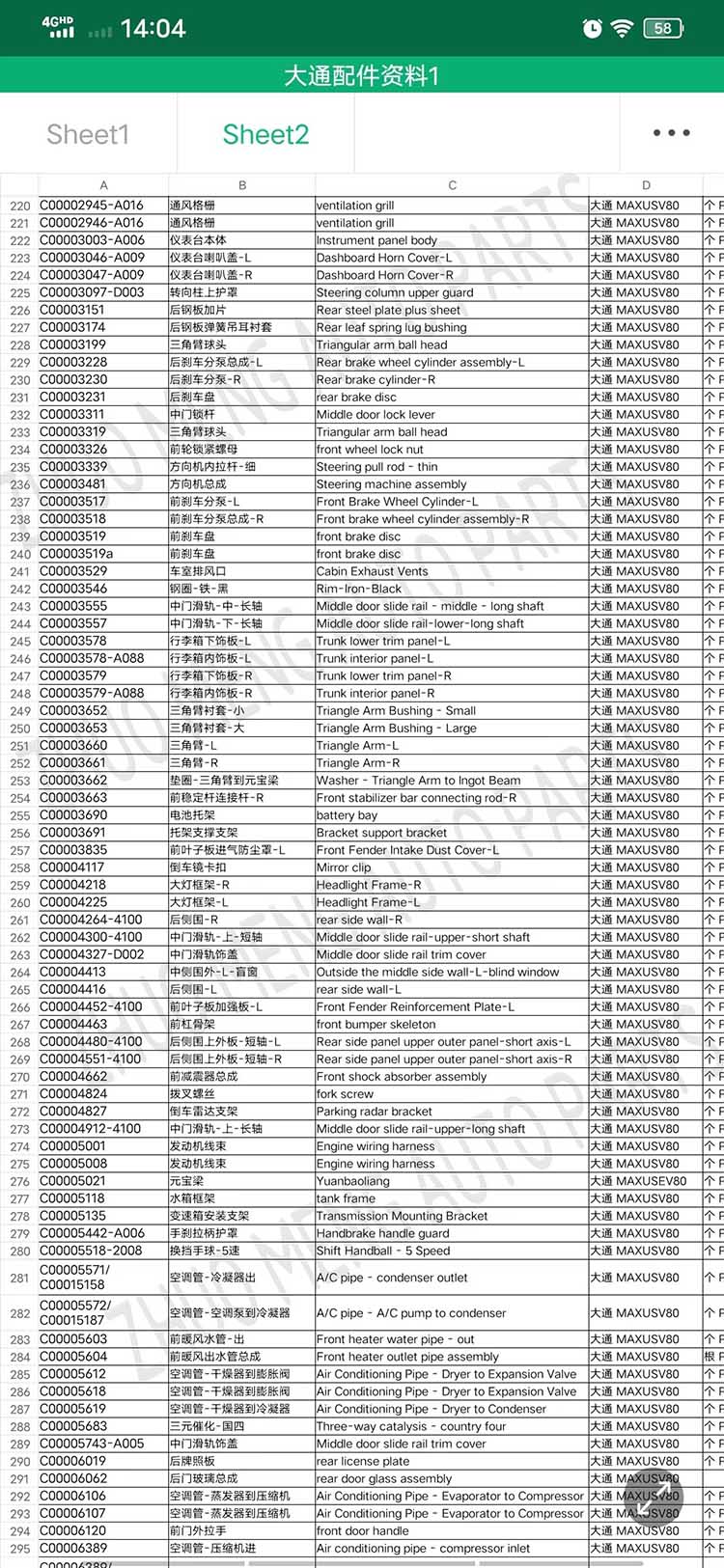

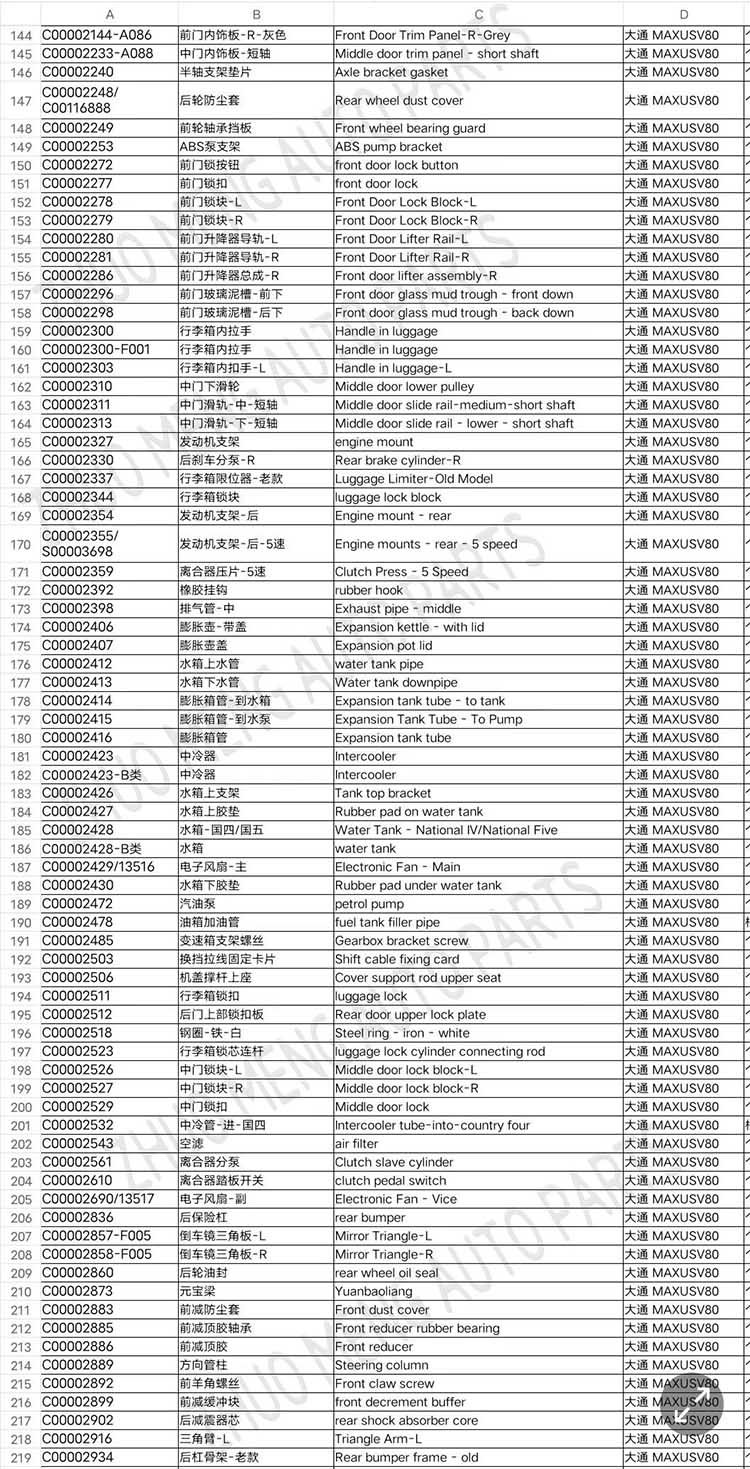

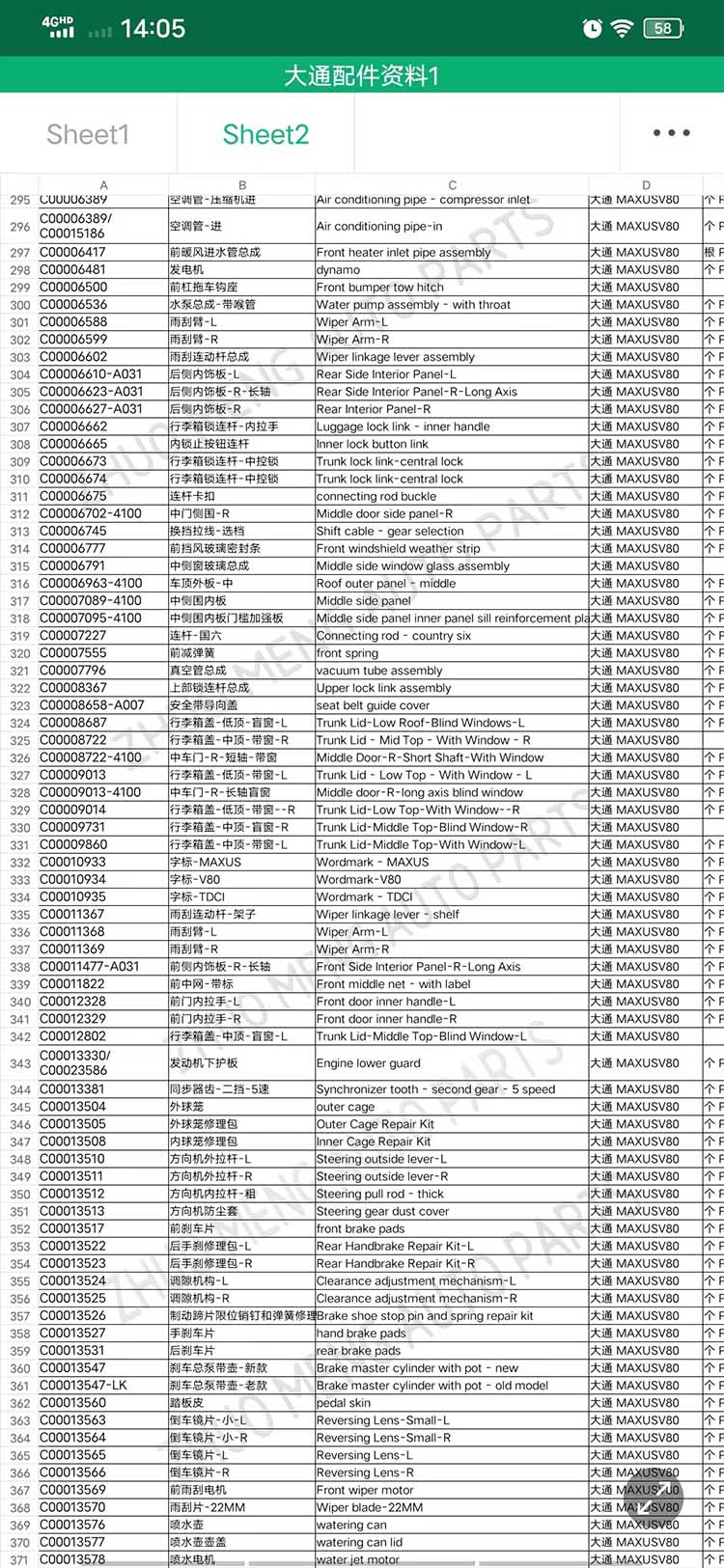

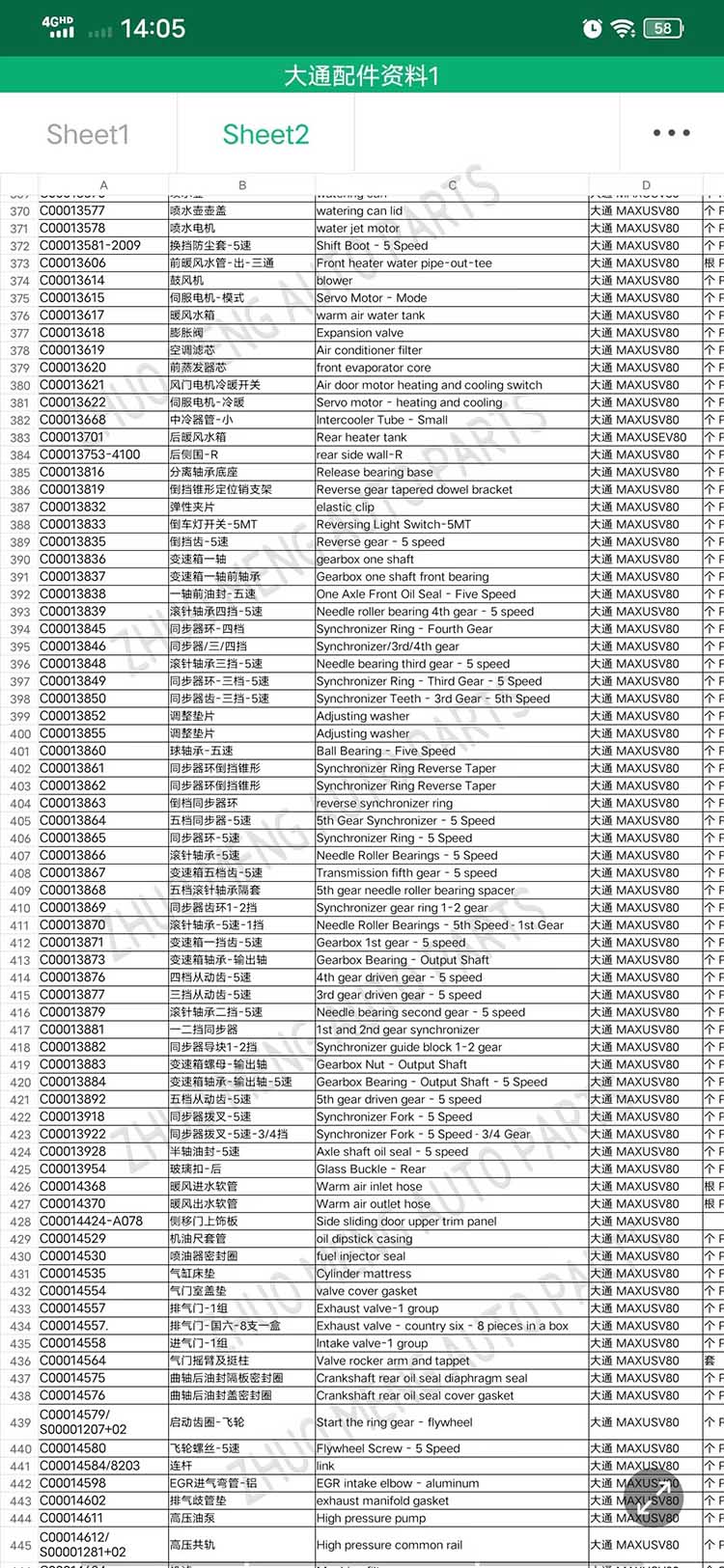

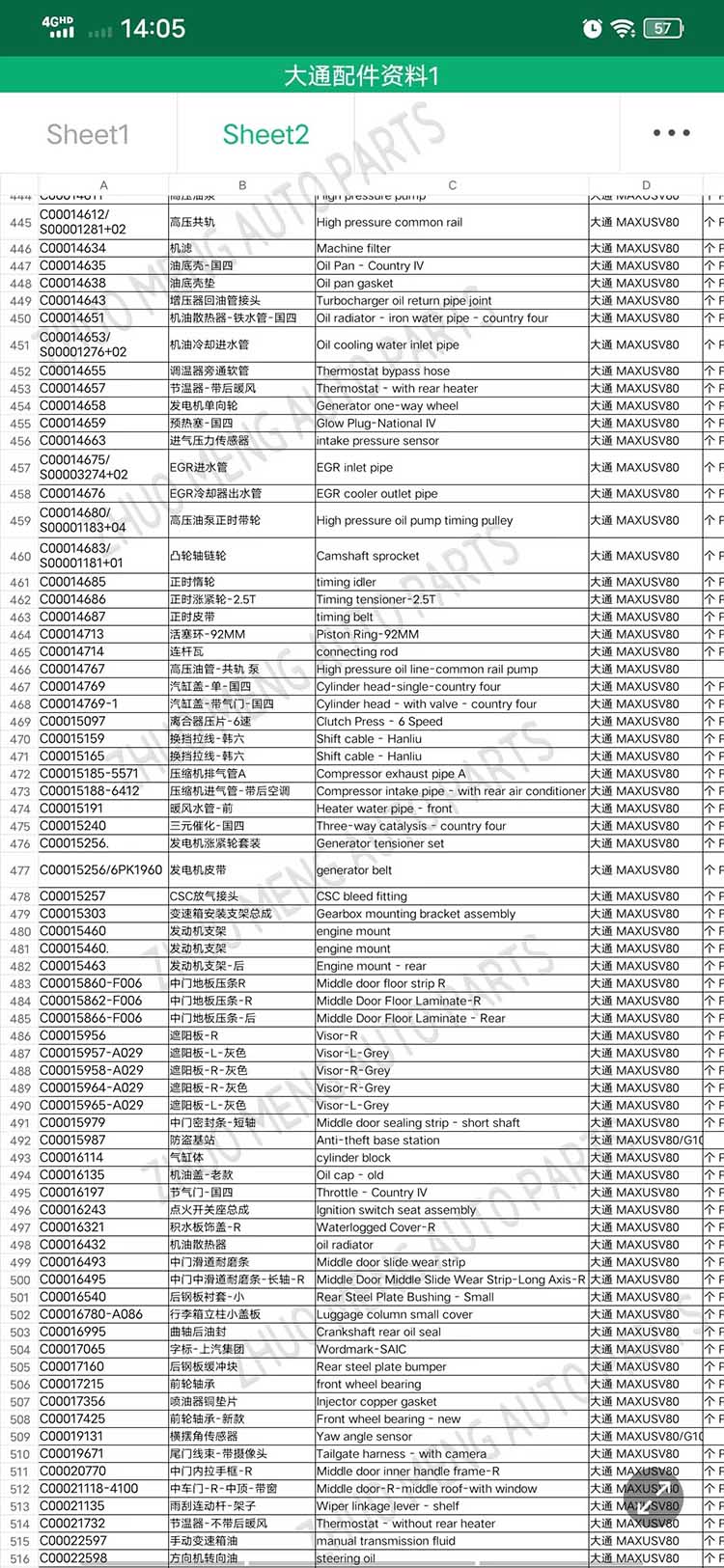

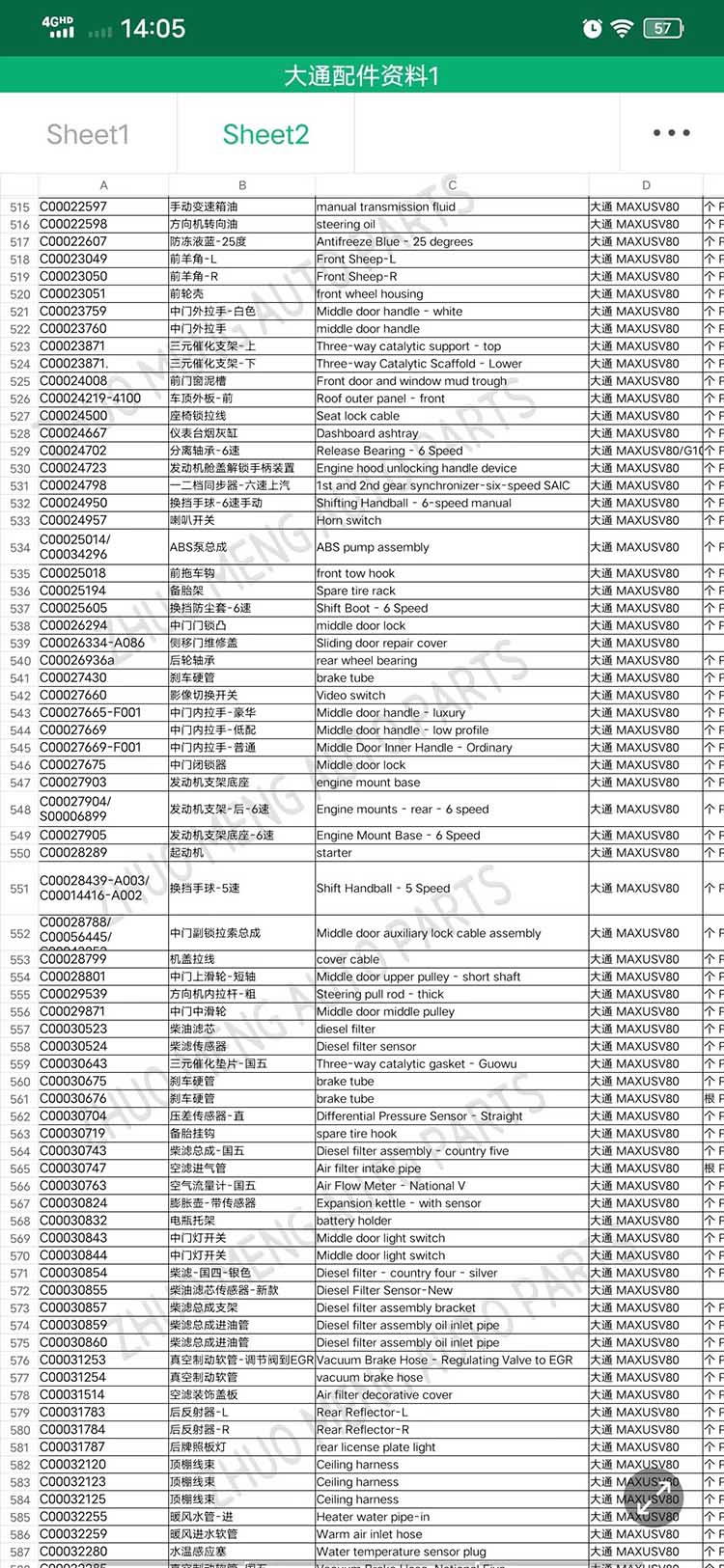

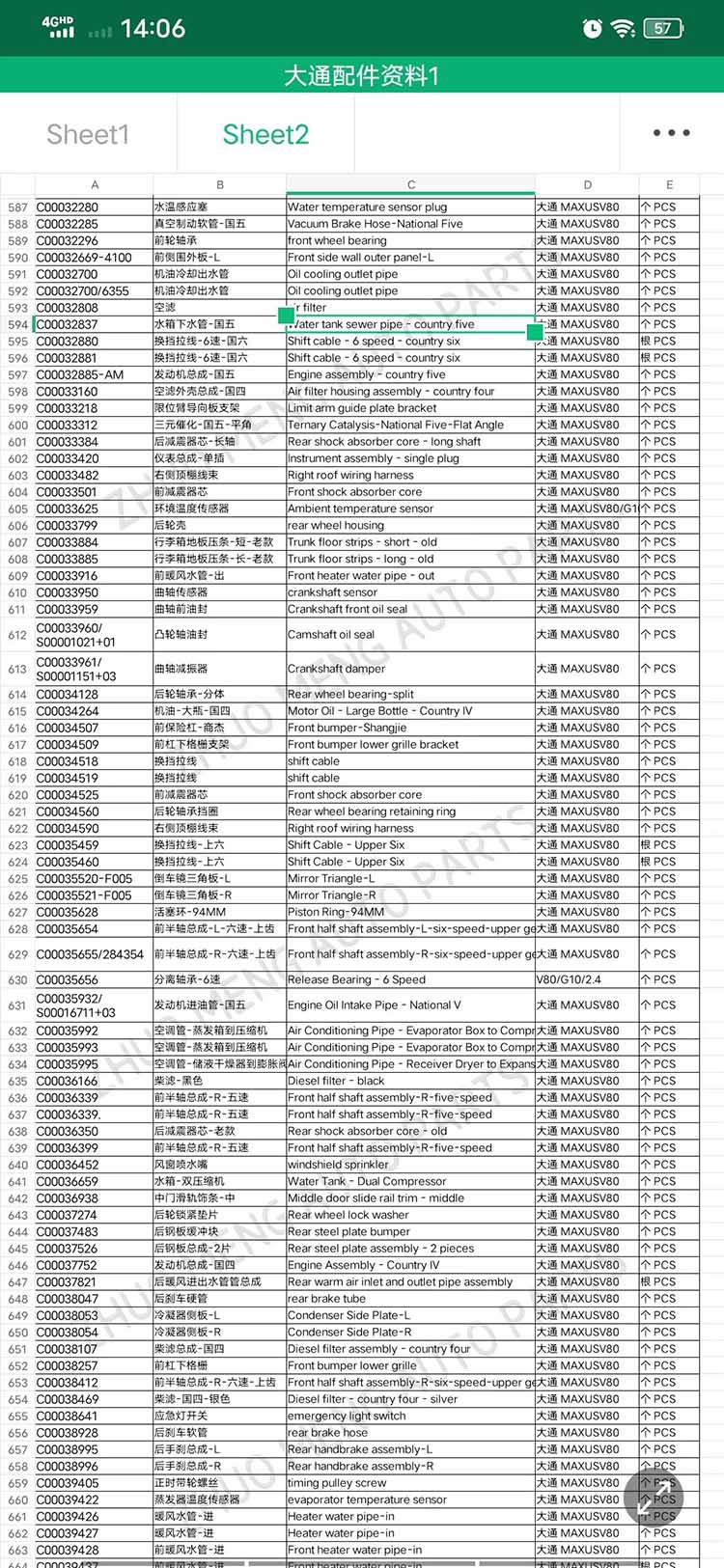

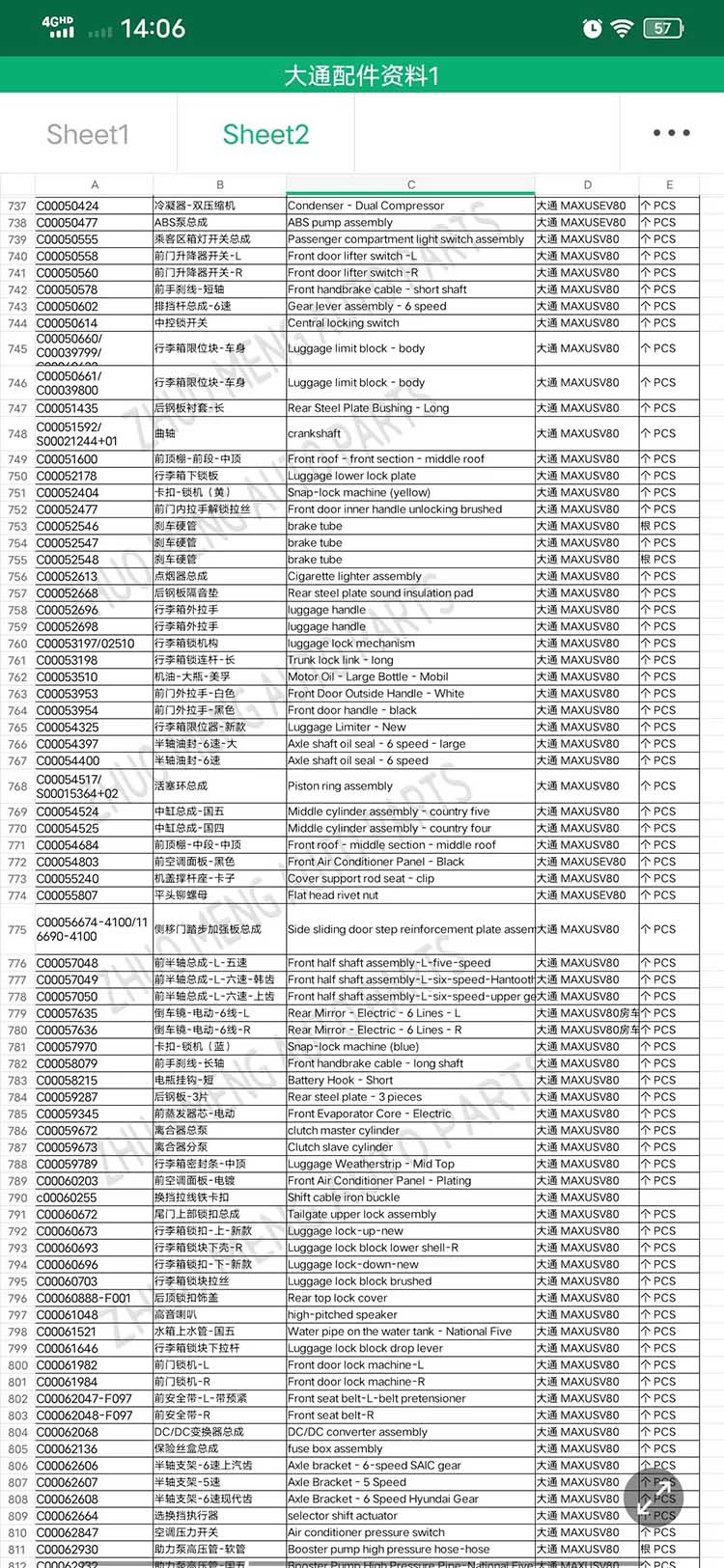

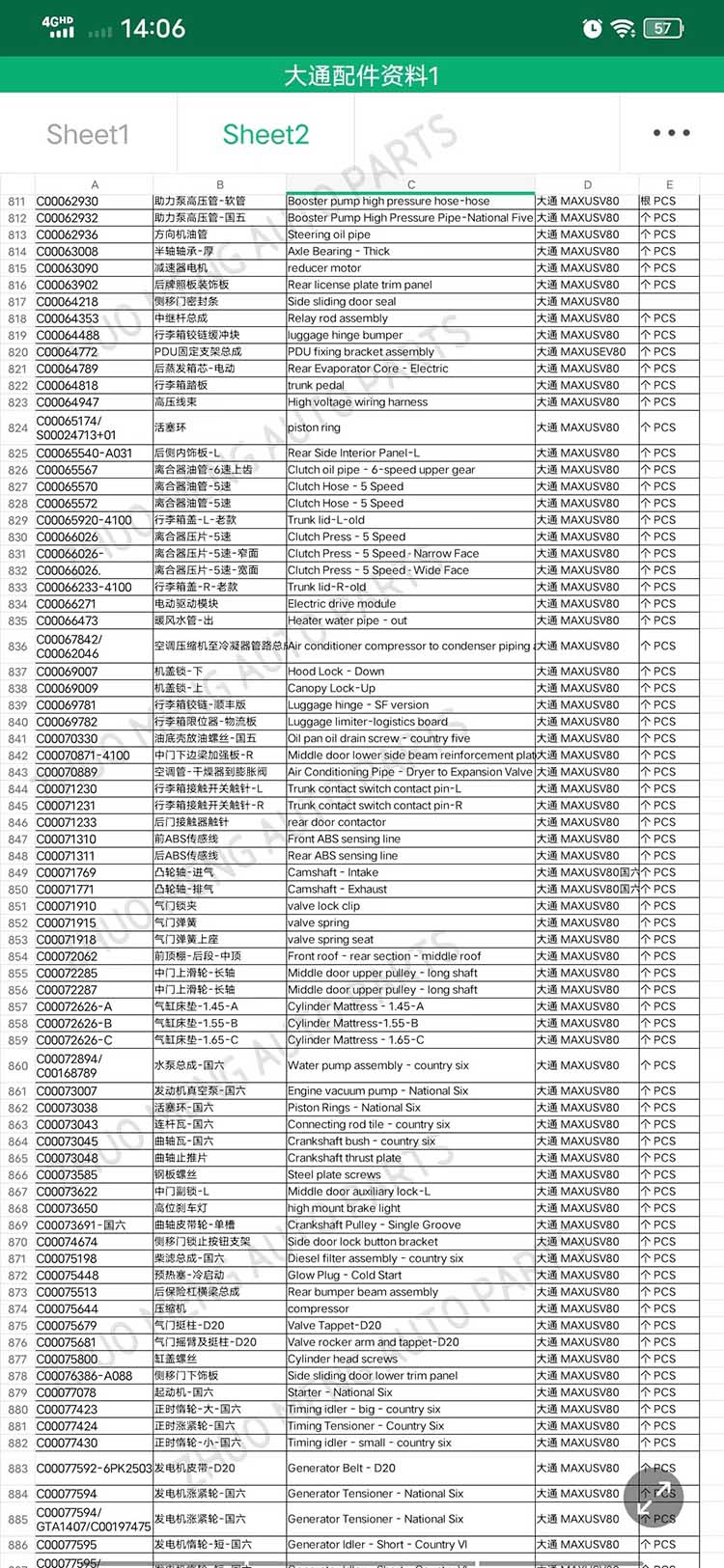

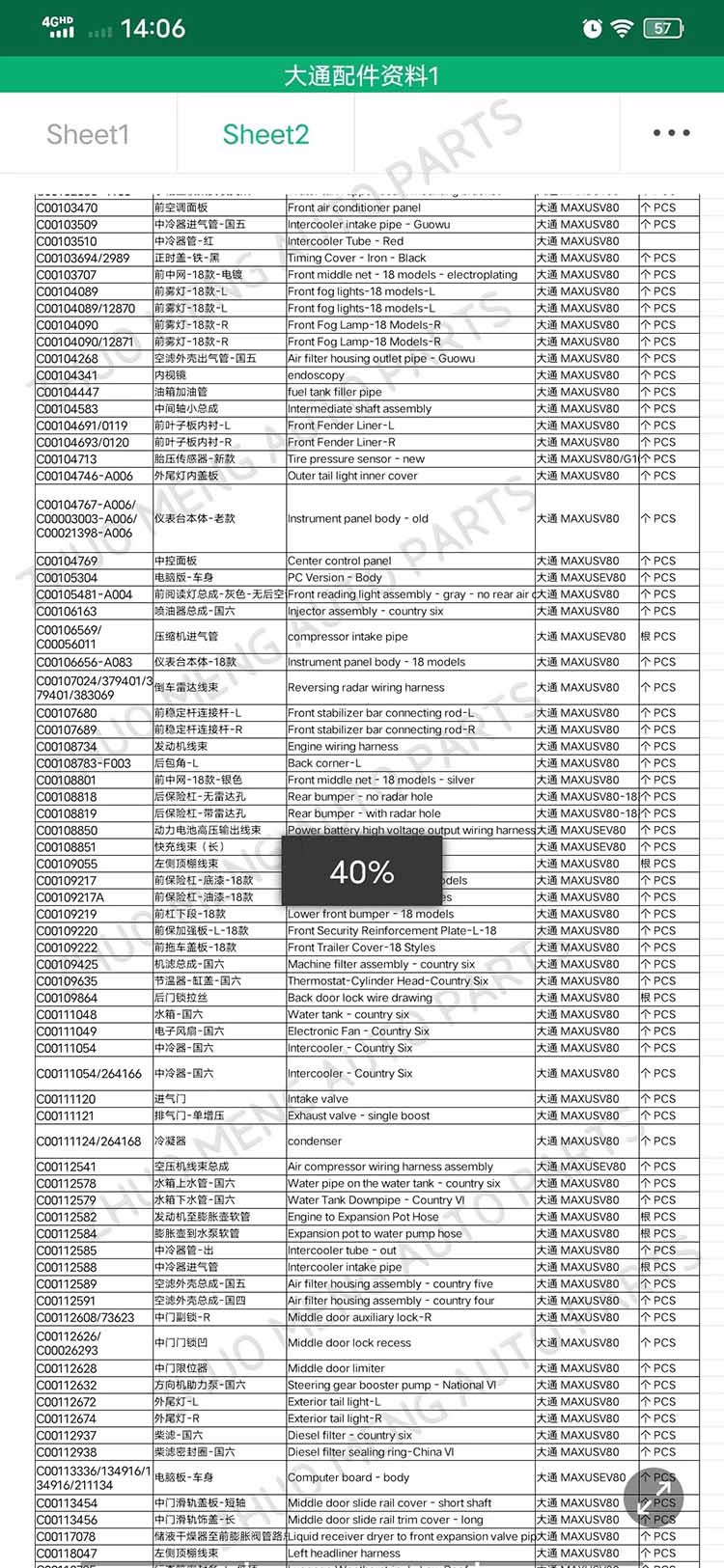

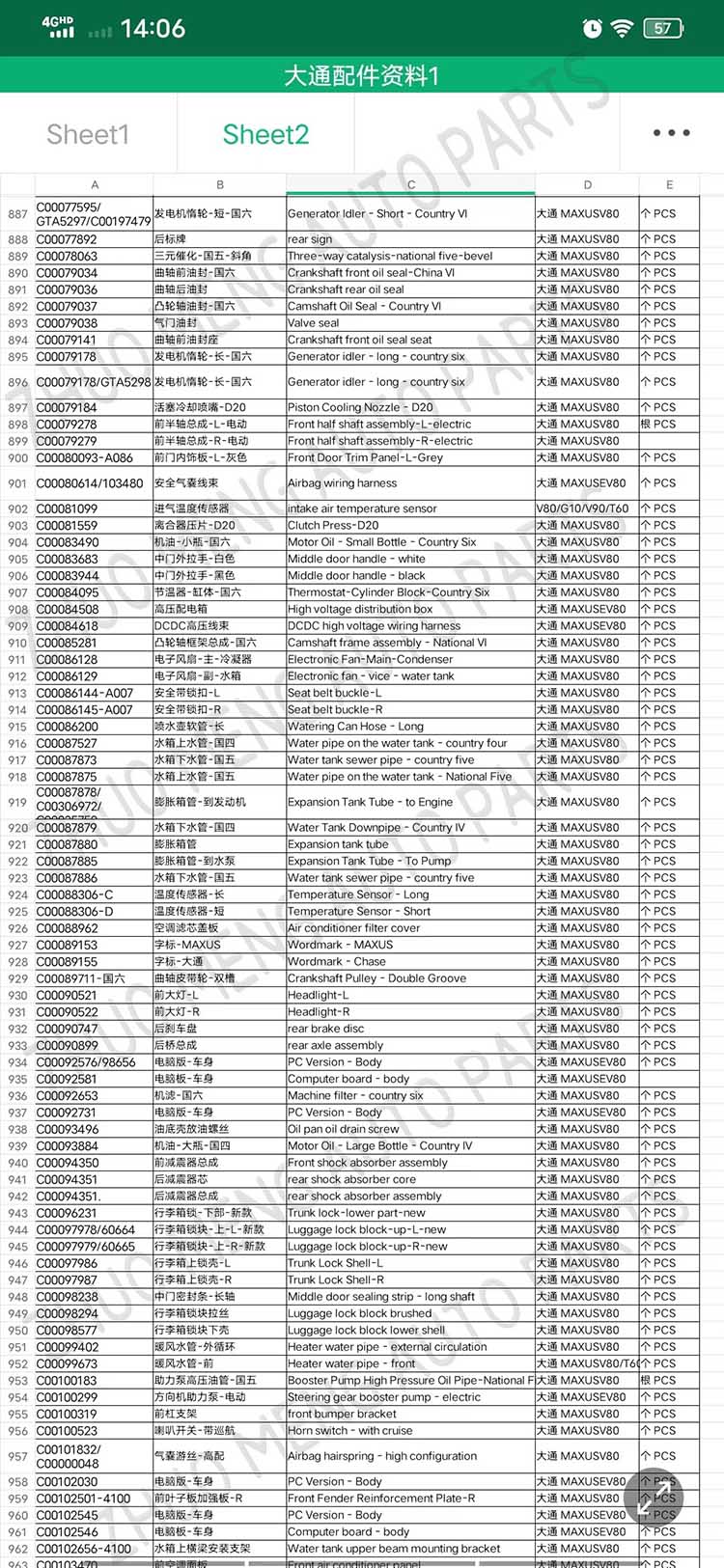

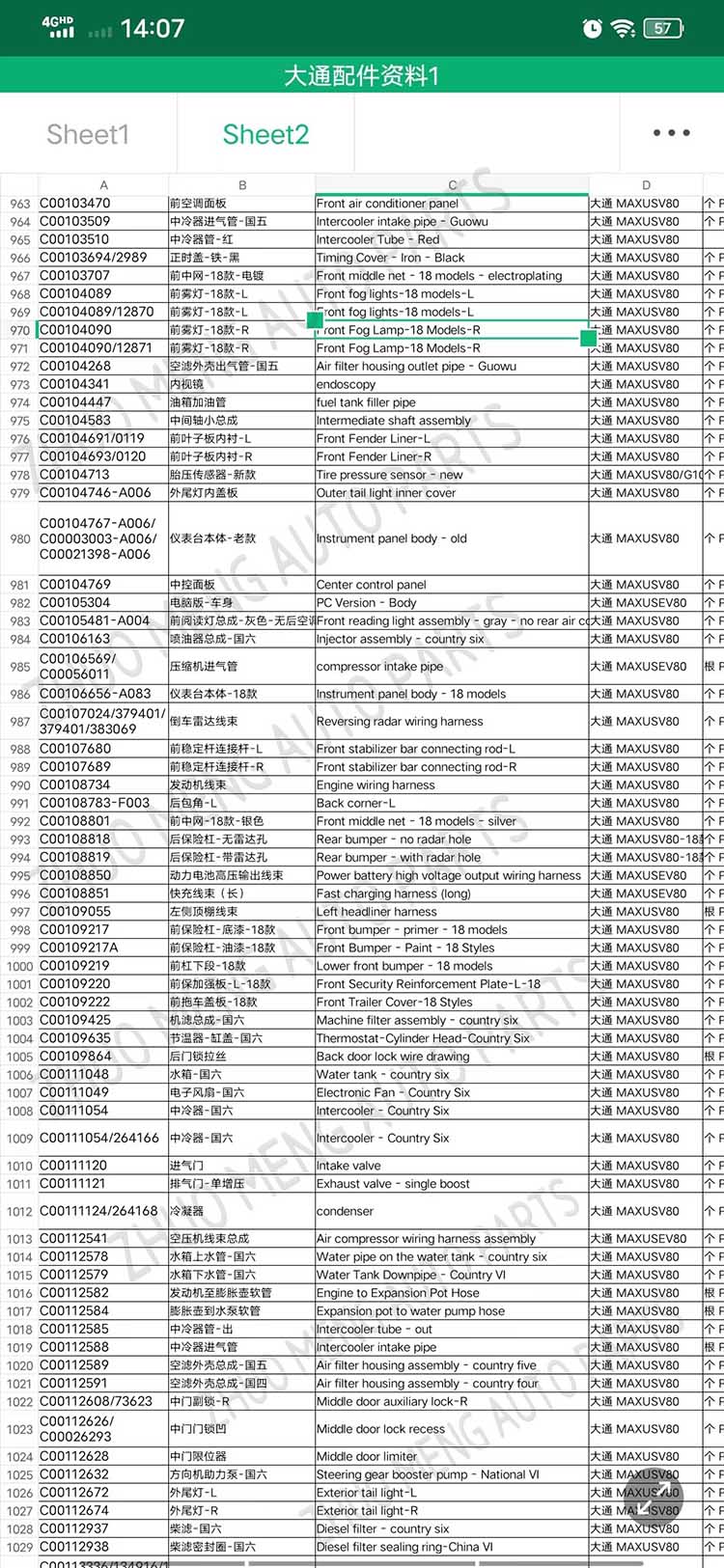

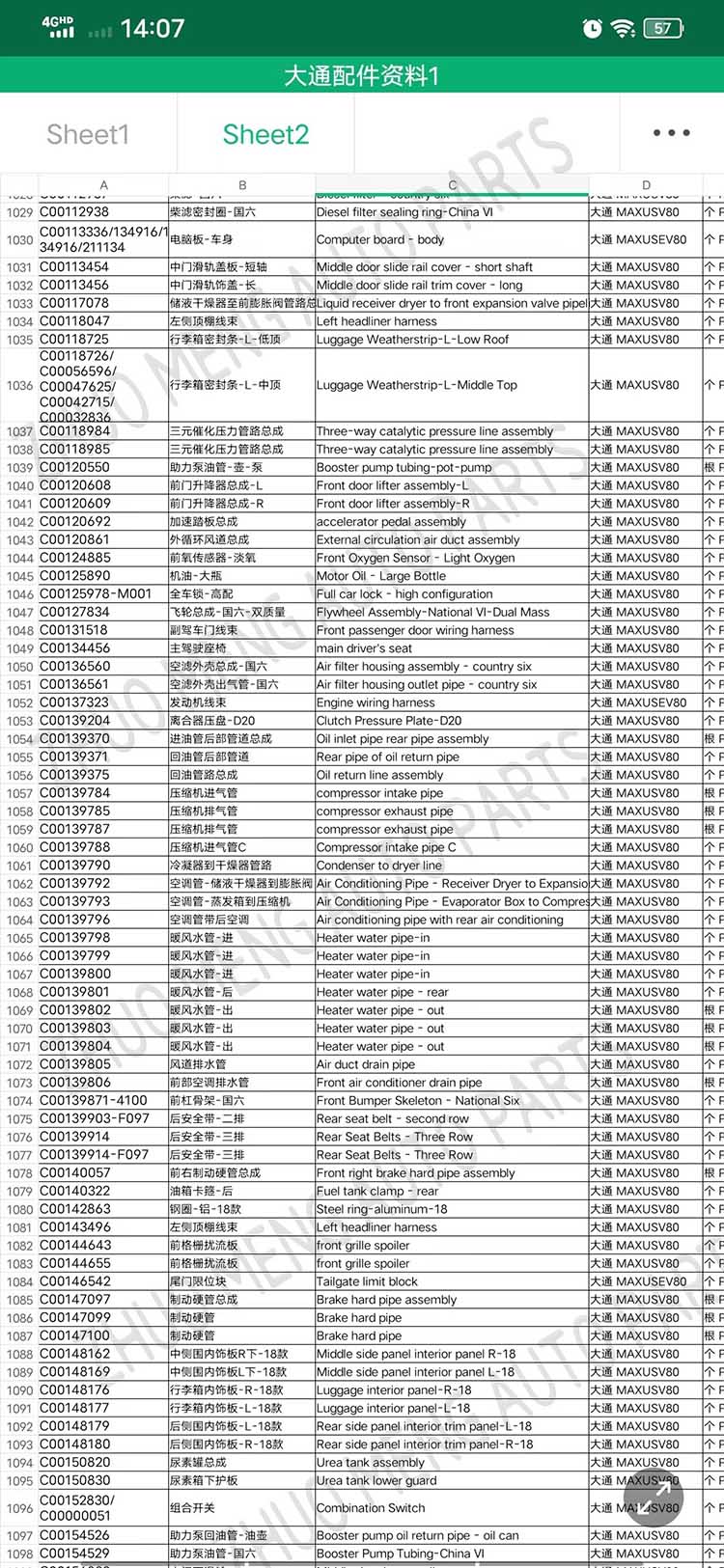

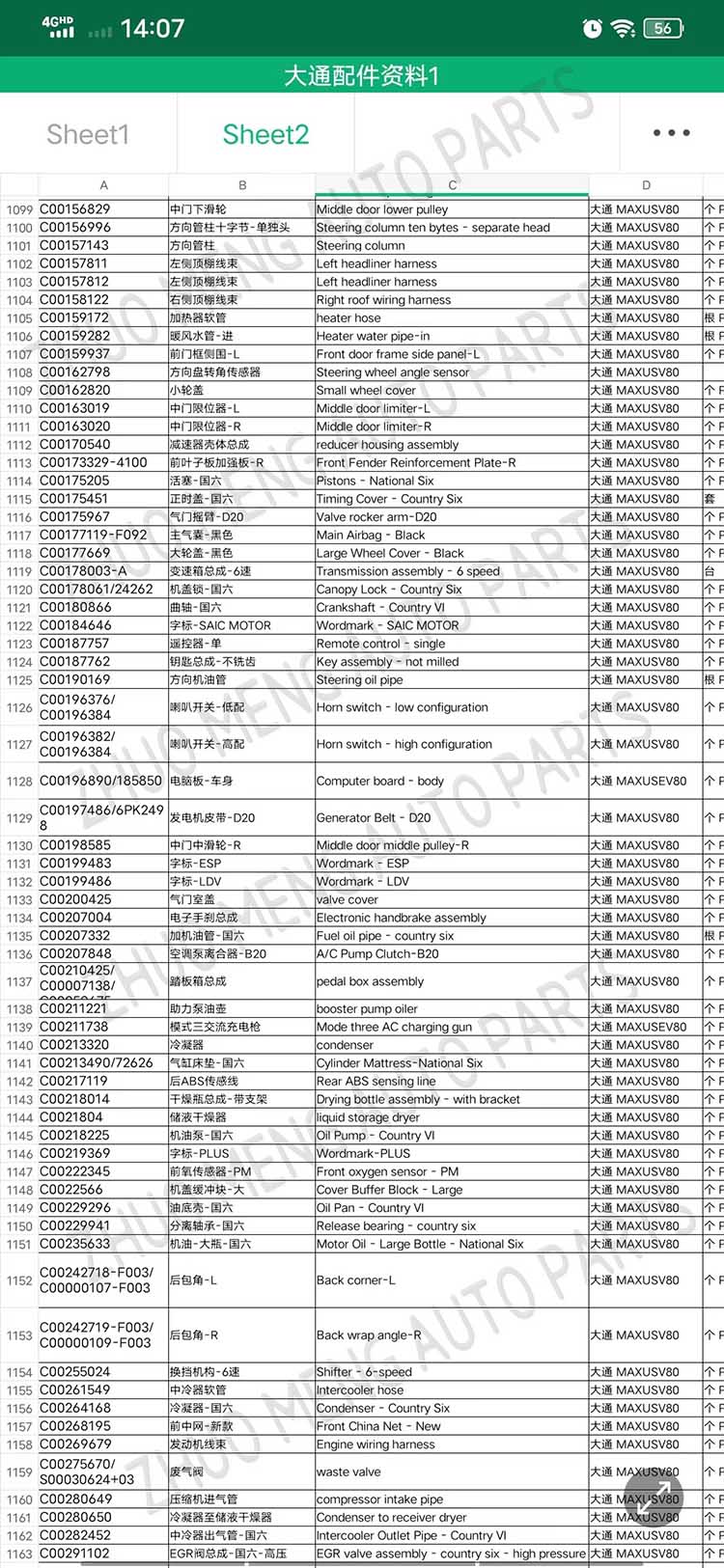

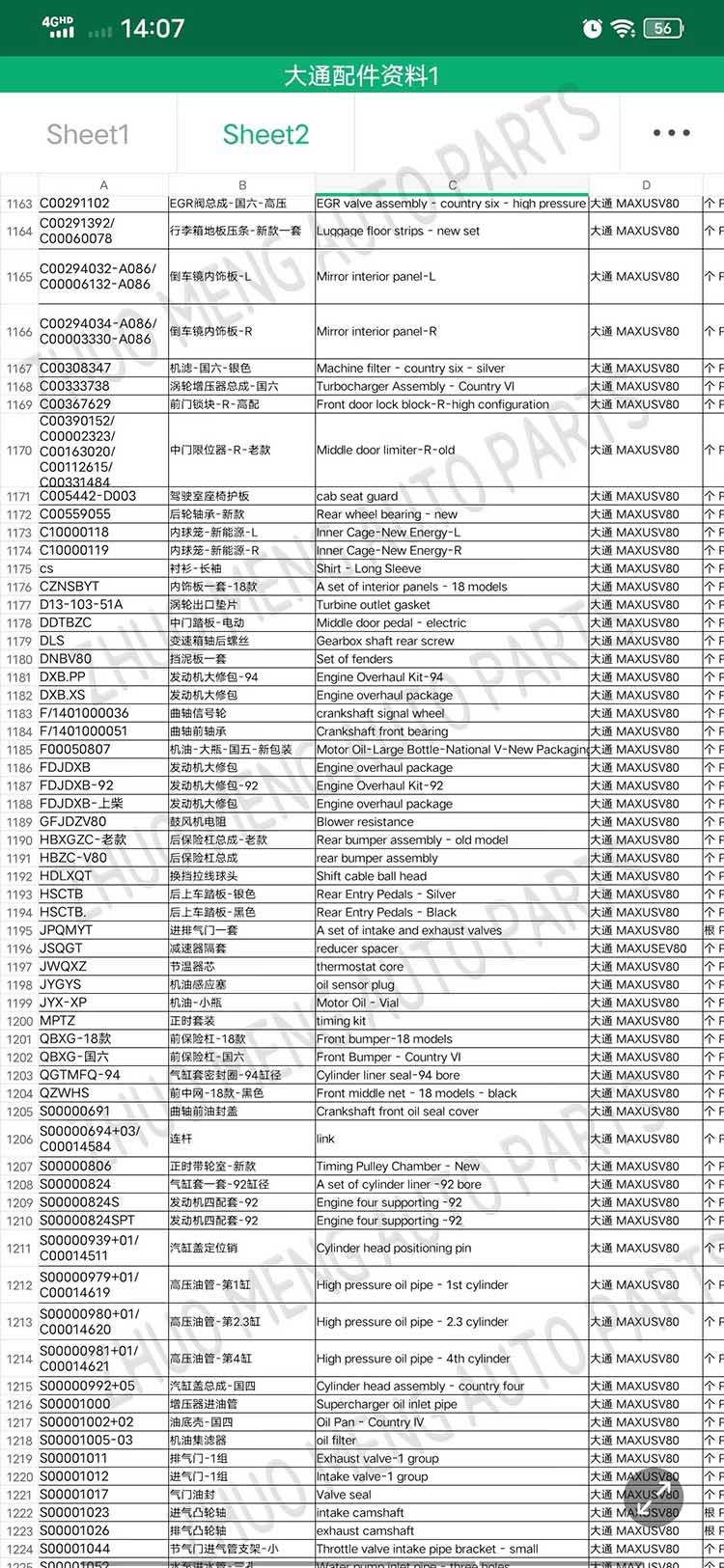

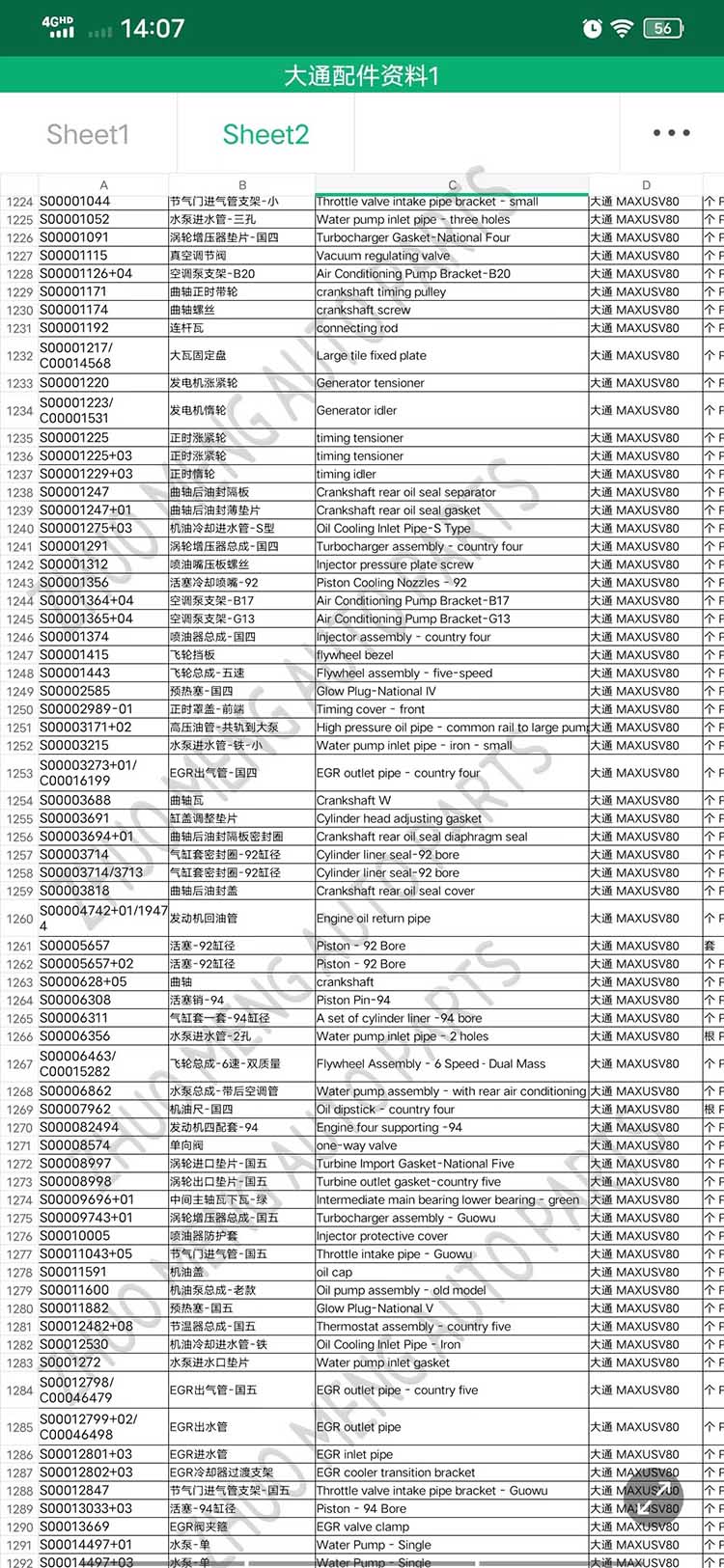

Products catalog

Related products

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Competitive Price for Mg 350 Accessories Wholesale - factory price SAIC MAXUS T60 C00021134 booster pump oil – Zhuomeng , The product will supply to all over the world, such as: Manchester, Kuwait, Poland, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.