China Manufacturer for Mgrx8 Spare Parts Manufacture - Factory direct sell SAIC MAXUS V80 C00014713 Piston Ring-92MM – Zhuomeng

China Manufacturer for Mgrx8 Spare Parts Manufacture - Factory direct sell SAIC MAXUS V80 C00014713 Piston Ring-92MM – Zhuomeng Detail:

Products information

| Products name | Piston Ring-92MM |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C00014713 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | POWER system |

Products knowledge

Piston Ring is a metal ring used to insert into the groove of the piston. There are two types of piston rings: compression ring and oil ring. The compression ring is used to seal the combustible mixture in the combustion chamber; the oil ring is used to scrape excess oil from the cylinder.

The piston ring is a metal elastic ring with large outward expansion deformation, which is assembled into the annular groove corresponding to the cross section. Reciprocating and rotating piston rings rely on the pressure difference of gas or liquid to form a seal between the outer circular surface of the ring and the cylinder and one side of the ring and the ring groove.

Piston rings are widely used in various power machinery, such as steam engines, diesel engines, gasoline engines, compressors, hydraulic machines, etc., and are widely used in automobiles, trains, ships, yachts, etc. Generally, the piston ring is installed in the ring groove of the piston, and it forms a chamber with the piston, cylinder liner, cylinder head and other components to do work.

significance

The piston ring is the core component inside the fuel engine, which completes the sealing of the fuel gas together with the cylinder, piston, cylinder wall, etc. Commonly used car engines are diesel and gasoline engines. Due to their different fuel performance, the piston rings used are also different. The early piston rings were formed by casting, but with the advancement of technology, steel high-power piston rings were born. , and with the continuous improvement of engine function and environmental requirements, various advanced surface treatment applications, such as thermal spraying, electroplating, chrome plating, gas nitriding, physical deposition, surface coating, zinc-manganese phosphating, etc., The function of the piston ring is greatly improved.

Function

The functions of the piston ring include four functions: sealing, regulating oil (oil control), heat conduction (heat transfer), and guiding (support). Sealing: refers to sealing the gas, preventing the gas in the combustion chamber from leaking into the crankcase, controlling the leakage of the gas to a minimum, and improving the thermal efficiency. Air leakage will not only reduce the power of the engine, but also deteriorate the oil, which is the main task of the air ring; Adjust the oil (oil control): scrape off the excess lubricating oil on the cylinder wall, and at the same time make the cylinder wall thin The thin oil film ensures the normal lubrication of the cylinder, piston and ring, which is the main task of the oil ring. In modern high-speed engines, special attention is paid to the role of the piston ring to control the oil film; heat conduction: the heat of the piston is conducted to the cylinder liner through the piston ring, that is, cooling. According to reliable data, 70-80% of the heat received by the piston top in the non-cooled piston is dissipated through the piston ring to the cylinder wall, and 30-40% of the cooled piston is transmitted to the cylinder through the piston ring Support: The piston ring keeps the piston in the cylinder, prevents the piston from directly contacting the cylinder wall, ensures the smooth movement of the piston, reduces frictional resistance, and prevents the piston from knocking the cylinder. Generally, the piston of gasoline engine uses two air rings and one oil ring, while diesel engine usually uses two oil rings and one air ring. [2]

characteristic

force

The forces acting on the piston ring include gas pressure, the elastic force of the ring itself, the inertial force of the reciprocating motion of the ring, the friction between the ring and the cylinder and the ring groove, etc. As a result of these forces, the ring will produce basic movements such as axial movement, radial movement, and rotational movement. In addition, due to its motion characteristics, along with irregular motion, the piston ring inevitably appears suspension and axial vibration, radial irregular motion and vibration, twisting motion, etc. caused by axial irregular motion. These irregular movements often prevent the piston rings from functioning. When designing the piston ring, it is necessary to give full play to the favorable motion and control the unfavorable side.

thermal conductivity

The high heat generated by combustion is transmitted to the cylinder wall through the piston ring, so it can cool the piston. The heat dissipated to the cylinder wall through the piston ring can generally reach 30 to 40 % of the heat absorbed by the top of the piston

air tightness

The first function of the piston ring is to maintain the seal between the piston and the cylinder wall and to control air leakage to a minimum. This role is mainly undertaken by the gas ring, that is, under any operating conditions of the engine, the leakage of compressed air and gas should be controlled to a minimum to improve thermal efficiency; to prevent the leakage between the cylinder and the piston or between the cylinder and the ring. Seize; prevent failure caused by deterioration of lubricating oil, etc.

Oil control

The second function of the piston ring is to properly scrape off the lubricating oil attached to the cylinder wall and maintain normal oil consumption. When the supplied lubricating oil is too much, it will be sucked into the combustion chamber, which will increase the fuel consumption, and will have a bad influence on the performance of the engine due to the carbon deposits produced by the combustion.

Supportive

Because the piston is slightly smaller than the inner diameter of the cylinder, if there is no piston ring, the piston is unstable in the cylinder and cannot move freely. At the same time, the ring also prevents the piston from directly contacting the cylinder and plays a supporting role. Therefore, the piston ring moves up and down in the cylinder, and its sliding surface is fully borne by the ring.

Classification

By structure

A. Monolithic structure: through the process of casting or integral molding.

b. Combined ring: A piston ring composed of two or more parts assembled in a ring groove.

c. Slotted oil ring: an oil ring with parallel sides, two contact land and oil return holes.

D. Slotted coil spring oil ring: add the oil ring of the coil support spring in the grooved oil ring. The support spring can increase the radial specific pressure, and its force on the inner surface of the ring is equal. Commonly found in diesel engine rings.

E. Steel belt combined oil ring: an oil ring composed of a lining ring and two scraper rings. The design of the backing ring varies by manufacturer and is commonly found in gasoline engine rings.

Section shape

Bucket ring, cone ring, inner chamfer twist ring, wedge ring and trapezoid ring, nose ring, outer shoulder twist ring, inner chamfer twist ring, steel belt combination oil ring, different chamfer oil ring, same To chamfer oil ring, cast iron coil spring oil ring, steel oil ring, etc.

By material

Cast iron, steel.

surface treatment

Nitride ring: The hardness of the nitride layer is above 950HV, the brittleness is grade 1, and it has good wear resistance and corrosion resistance. Chrome-plated ring: The chrome-plated layer is fine, compact and smooth, with a hardness of more than 850HV, very good wear resistance, and a network of criss-crossing micro-cracks, which is conducive to the storage of lubricating oil. Phosphating ring: Through chemical treatment, a layer of phosphating film is formed on the surface of the piston ring, which plays an anti-rust effect on the product and also improves the initial running-in performance of the ring. Oxidation ring: Under the condition of high temperature and strong oxidant, an oxide film is formed on the surface of steel material, which has corrosion resistance, anti-friction lubrication and good appearance. There are PVD and so on.

according to function

There are two types of piston rings: gas ring and oil ring. The function of the gas ring is to ensure the seal between the piston and the cylinder. It prevents the high-temperature and high-pressure gas in the cylinder from leaking into the crankcase in large quantities, and at the same time conducts most of the heat from the top of the piston to the cylinder wall, which is then taken away by cooling water or air.

The oil ring is used to scrape the excess oil on the cylinder wall, and coat a uniform oil film on the cylinder wall, which can not only prevent the oil from entering the cylinder and burn, but also reduce the wear and tear of the piston, piston ring and cylinder. frictional resistance. [1]

usage

Good or bad identification

The working surface of the piston ring shall not have nicks, scratches and peelings, the outer cylindrical surface and the upper and lower end surfaces shall have a certain smoothness, the curvature deviation shall not be greater than 0.02-0.04 mm, and the standard sinking amount of the ring in the groove shall not exceed 0.15-0.25 mm, the elasticity and clearance of the piston ring meet the regulations. In addition, the light leakage degree of the piston ring should also be checked, that is, the piston ring should be placed flat in the cylinder, a small light cannon should be placed under the piston ring, and a shading plate should be placed on it, and then the light leakage gap between the piston ring and the cylinder wall should be observed. This shows whether the contact between the piston ring and the cylinder wall is good. In general, the light leakage gap of the piston ring should not exceed 0.03 mm when measured with a thickness gauge. The length of the continuous light leakage slit should not be greater than 1/3 of the cylinder diameter, the length of several light leakage slits should not be greater than 1/3 of the cylinder diameter, and the total length of several light leakage should not exceed 1/2 of the cylinder diameter, otherwise, it should be replaced.

marking regulations

Piston ring marking GB/T 1149.1-94 stipulates that all piston rings requiring installation direction should be marked on the upper side, that is, the side close to the combustion chamber. The rings marked on the upper side include: conical ring, inner chamfer, outer cut table ring, nose ring, wedge ring and oil ring that requires installation direction, and the upper side of the ring is marked.

Precautions

Pay attention when installing piston rings

1) The piston ring is flatly installed into the cylinder liner, and there must be a certain opening gap at the interface.

2) The piston ring should be installed on the piston, and in the ring groove, there should be a certain side clearance along the height direction.

3) The chrome-plated ring should be installed in the first channel, and the opening should not face the direction of the eddy current pit on the top of the piston.

4) The openings of each piston ring are staggered by 120°C, and are not allowed to face the piston pin hole.

5) For piston rings with tapered section, the tapered surface should be upwards during installation.

6) Generally, when the torsion ring is installed, the chamfer or groove should be upward; when the tapered anti-torsion ring is installed, keep the cone facing upward.

7) When installing the combined ring, the axial lining ring should be installed first, and then the flat ring and the wave ring should be installed. A flat ring is installed on the top and bottom of the wave ring, and the openings of each ring should be staggered from each other.

Material function

1. Wear resistance

2. Oil storage

3. Hardness

4. Corrosion resistance

5. Strength

6. Heat resistance

7. Elasticity

8. Cutting performance

Among them, wear resistance and elasticity are the most important. High-power diesel engine piston ring materials mainly include gray cast iron, ductile iron, alloy cast iron, and vermicular graphite cast iron.

Piston connecting rod assembly

The main points of the assembly of the diesel generator piston connecting rod group are as follows:

1. Press-fit connecting rod copper sleeve. When installing the copper sleeve of the connecting rod, it is best to use a press or a vise, and do not beat it with a hammer; the oil hole or oil groove on the copper sleeve should be aligned with the oil hole on the connecting rod to ensure its lubrication

2. Assemble the piston and connecting rod. When assembling the piston and connecting rod, pay attention to their relative position and orientation.

Three, cleverly installed piston pin. The piston pin and the pin hole are an interference fit. When installing, first place the piston in water or oil and evenly heat it to 90°C~100°C. After taking it out, put the tie rod in the proper position between the piston pin seat holes, and then install the oil-coated piston pin in the predetermined direction. into the piston pin hole and the connecting rod copper sleeve

Fourth, the installation of the piston ring. When installing piston rings, pay attention to the position and order of each ring.

Fifth, install the connecting rod group.

Related products

GOOD FEETBACK

OUR EXHIBITION

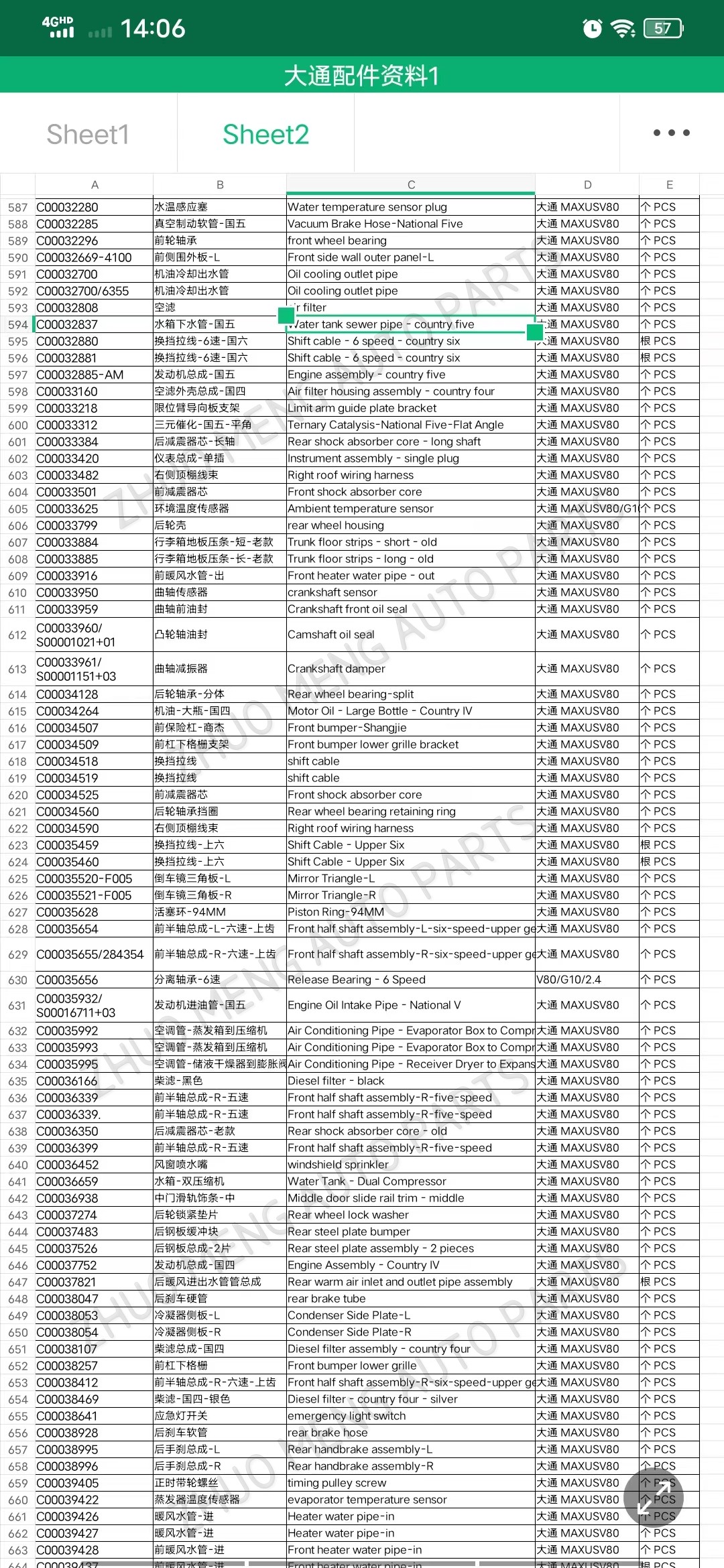

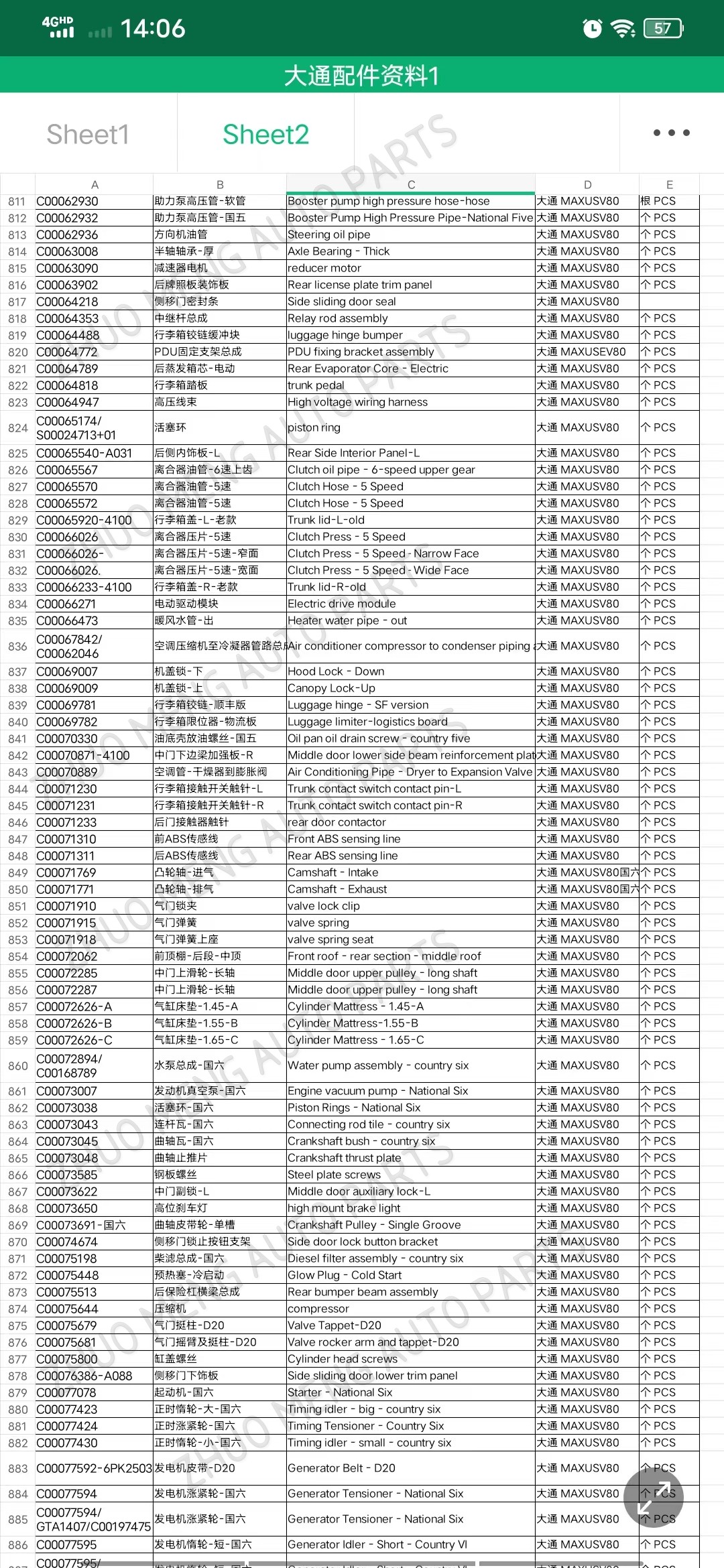

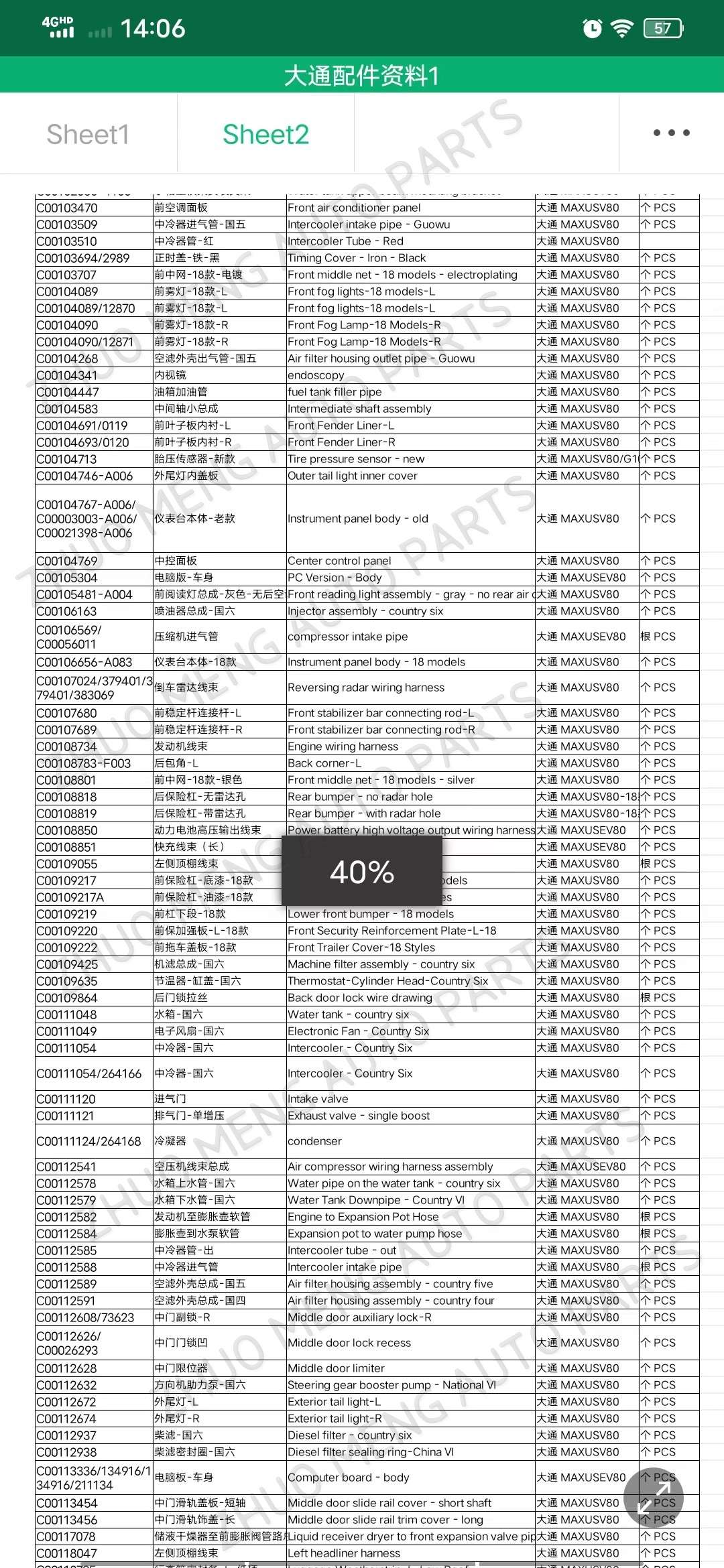

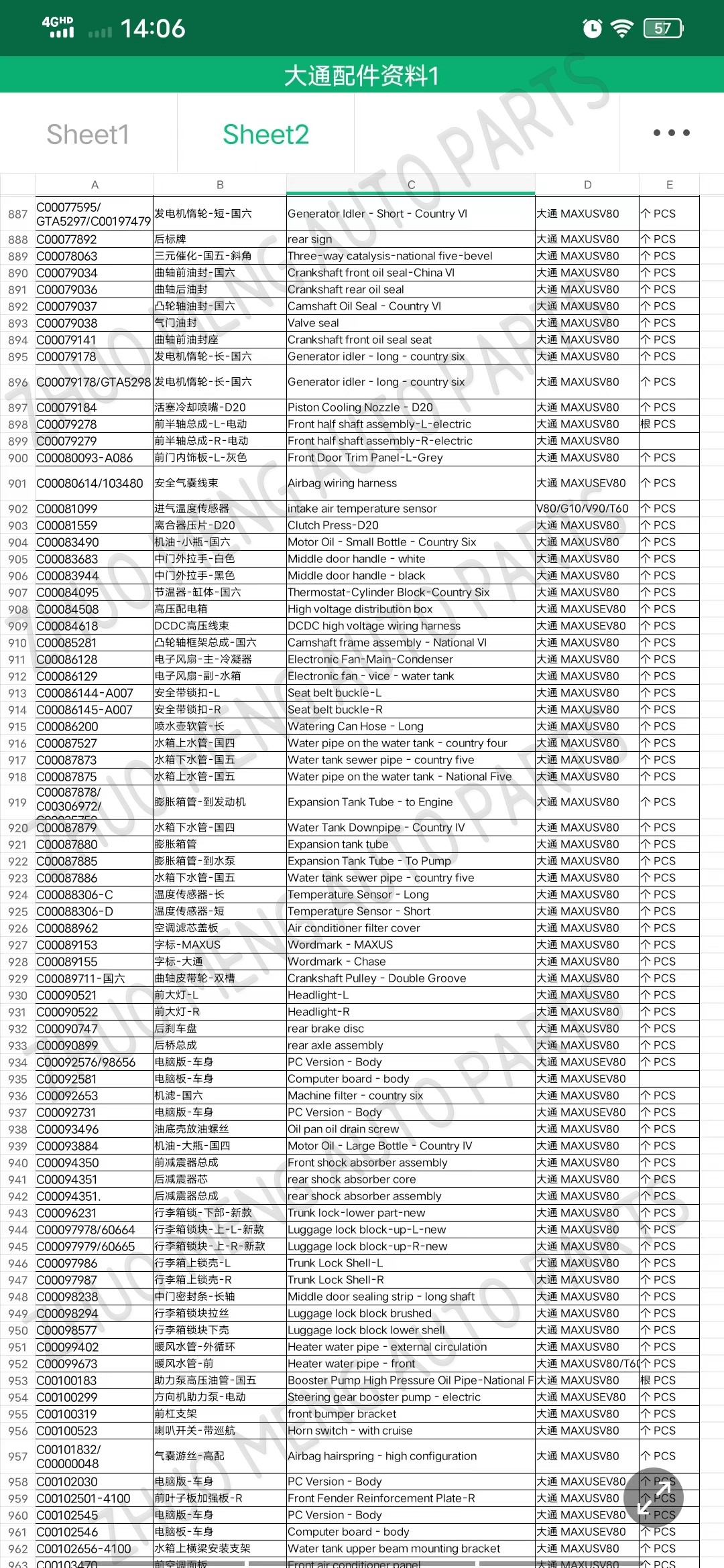

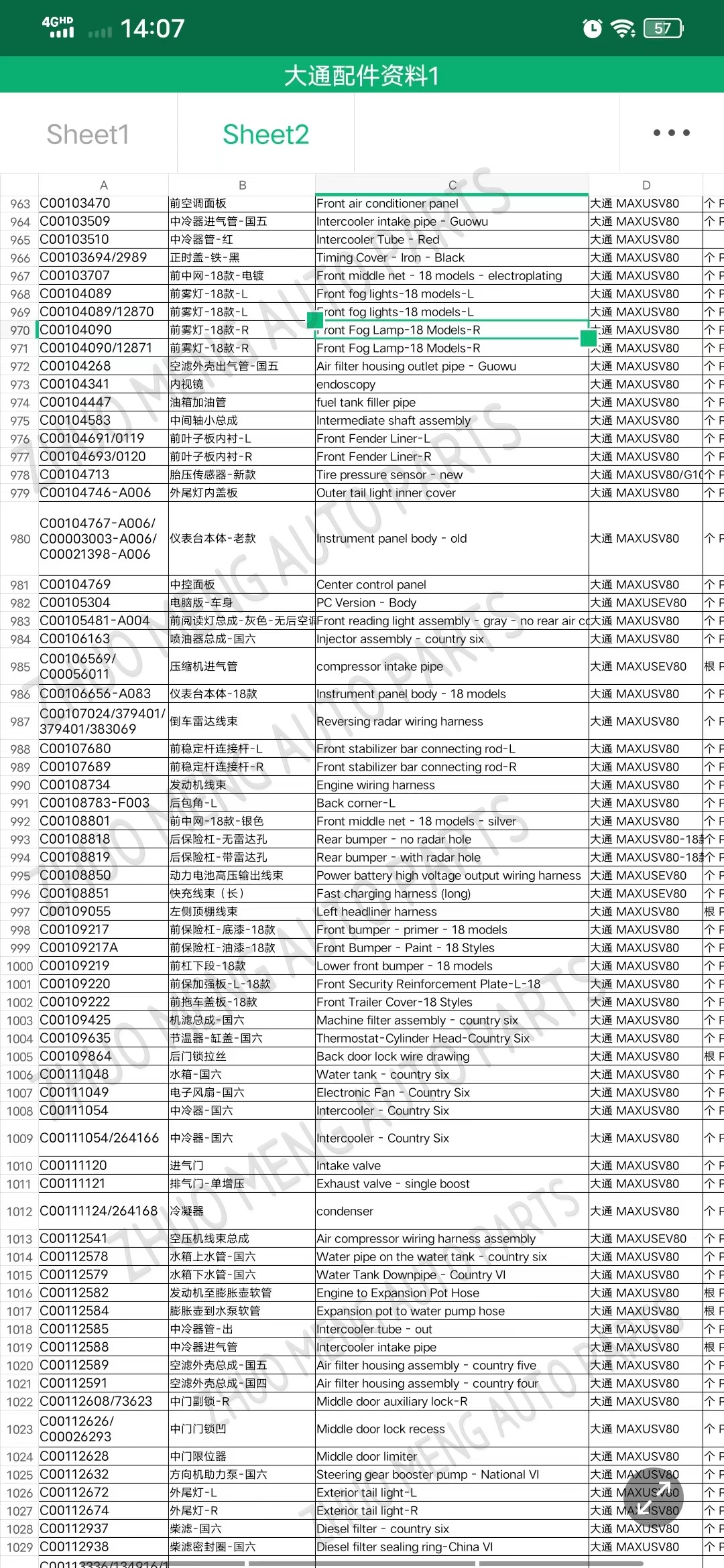

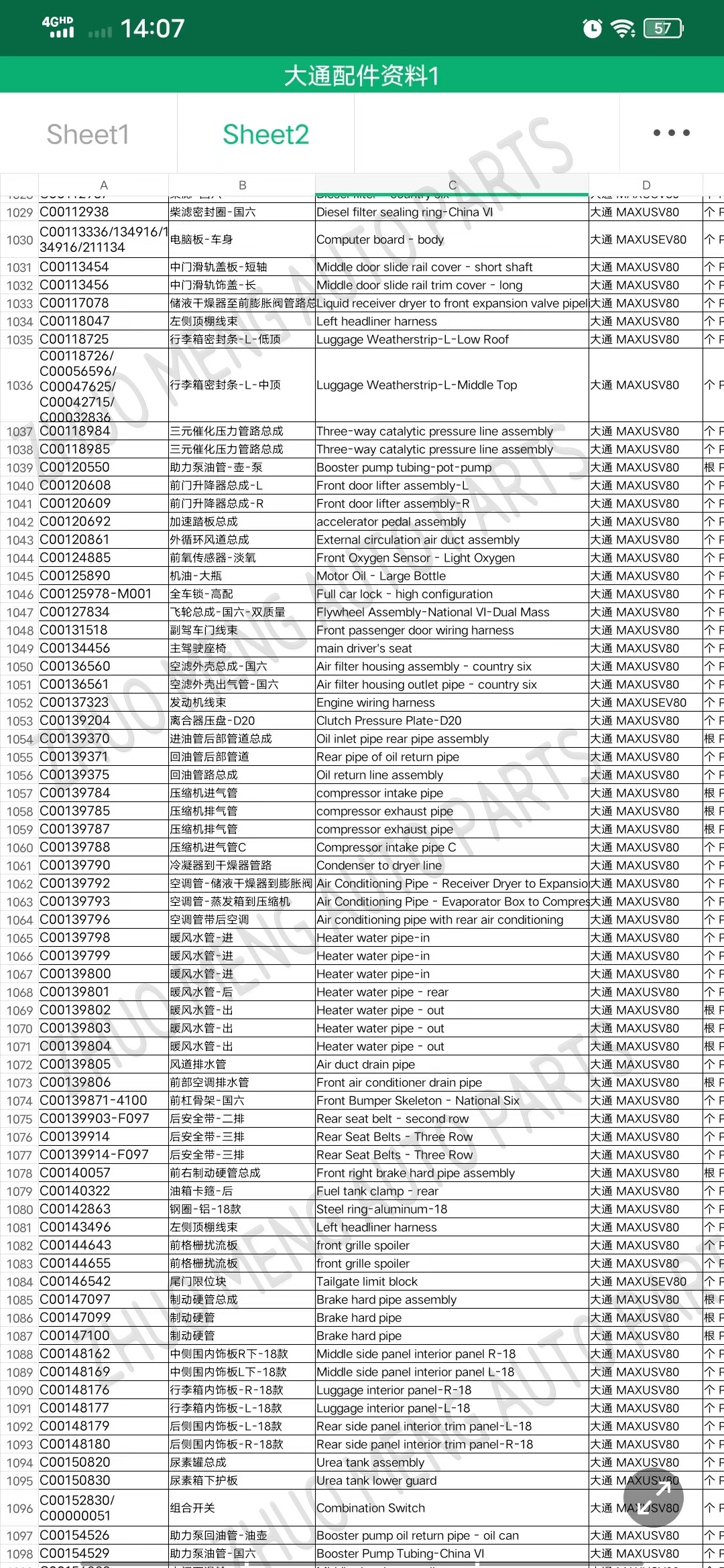

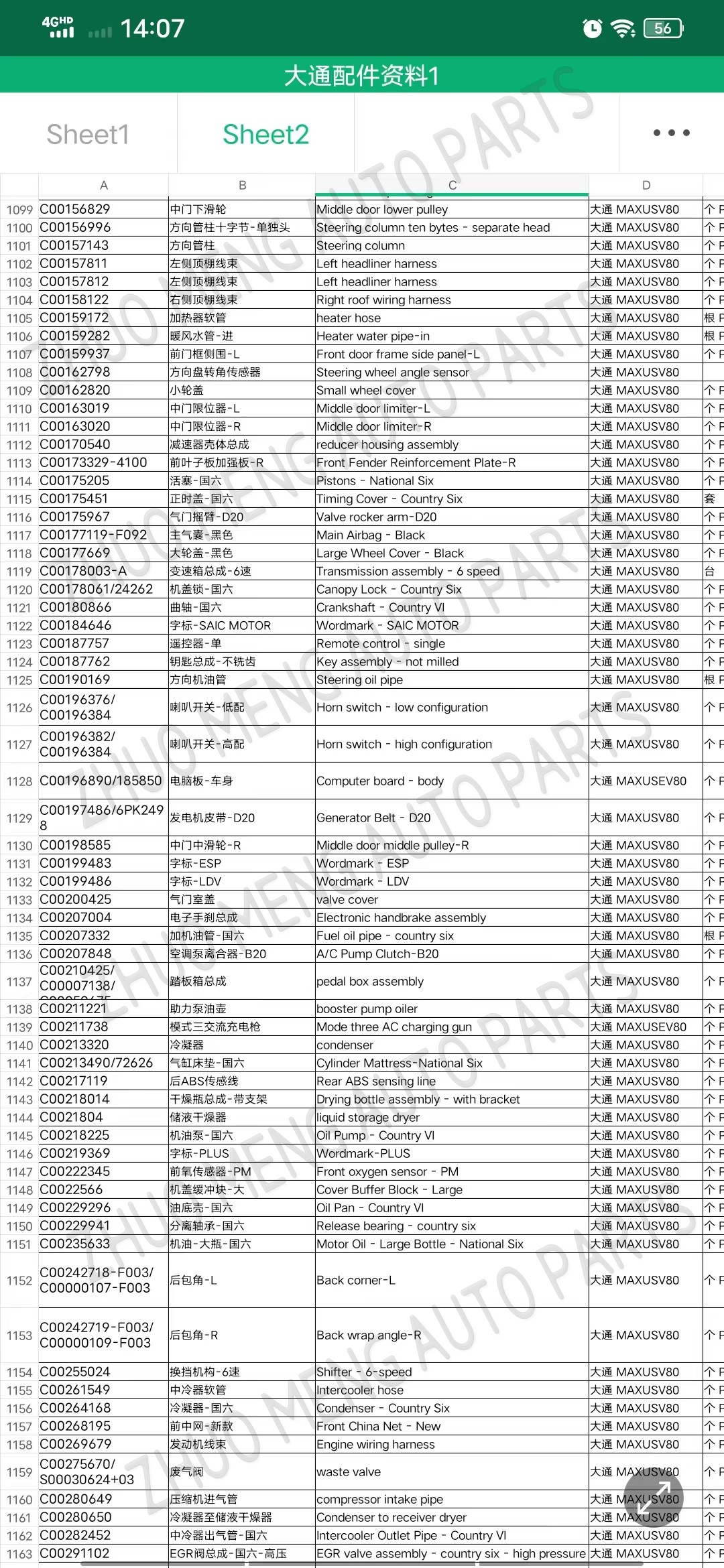

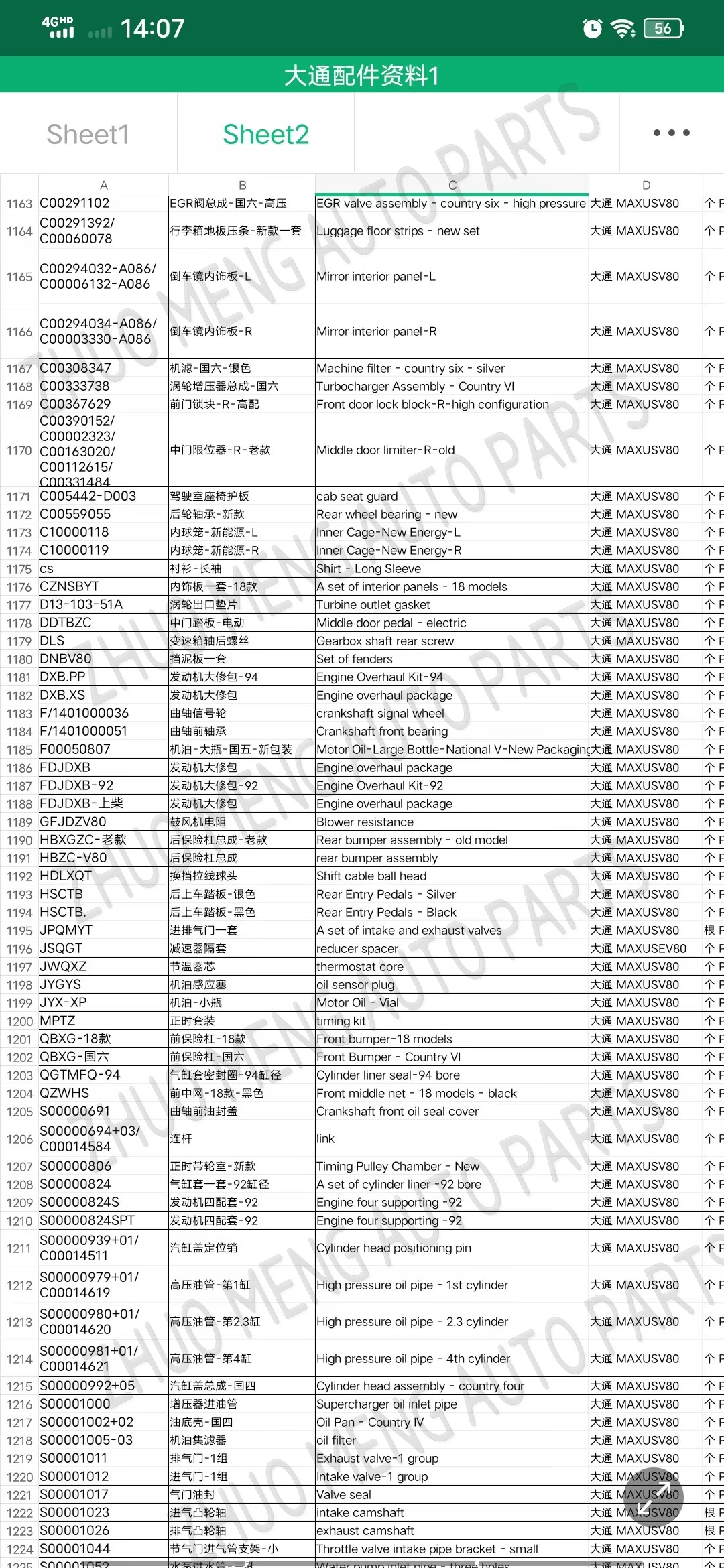

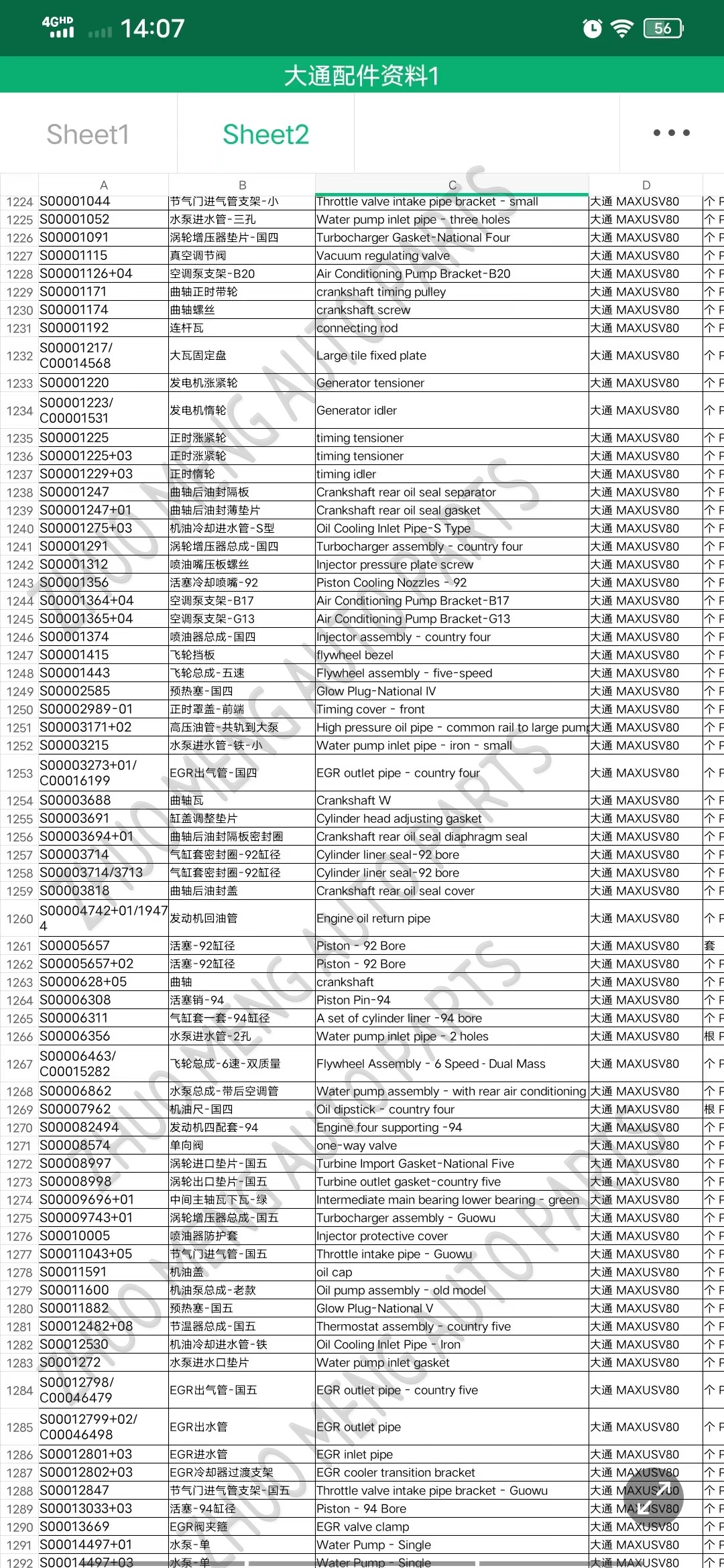

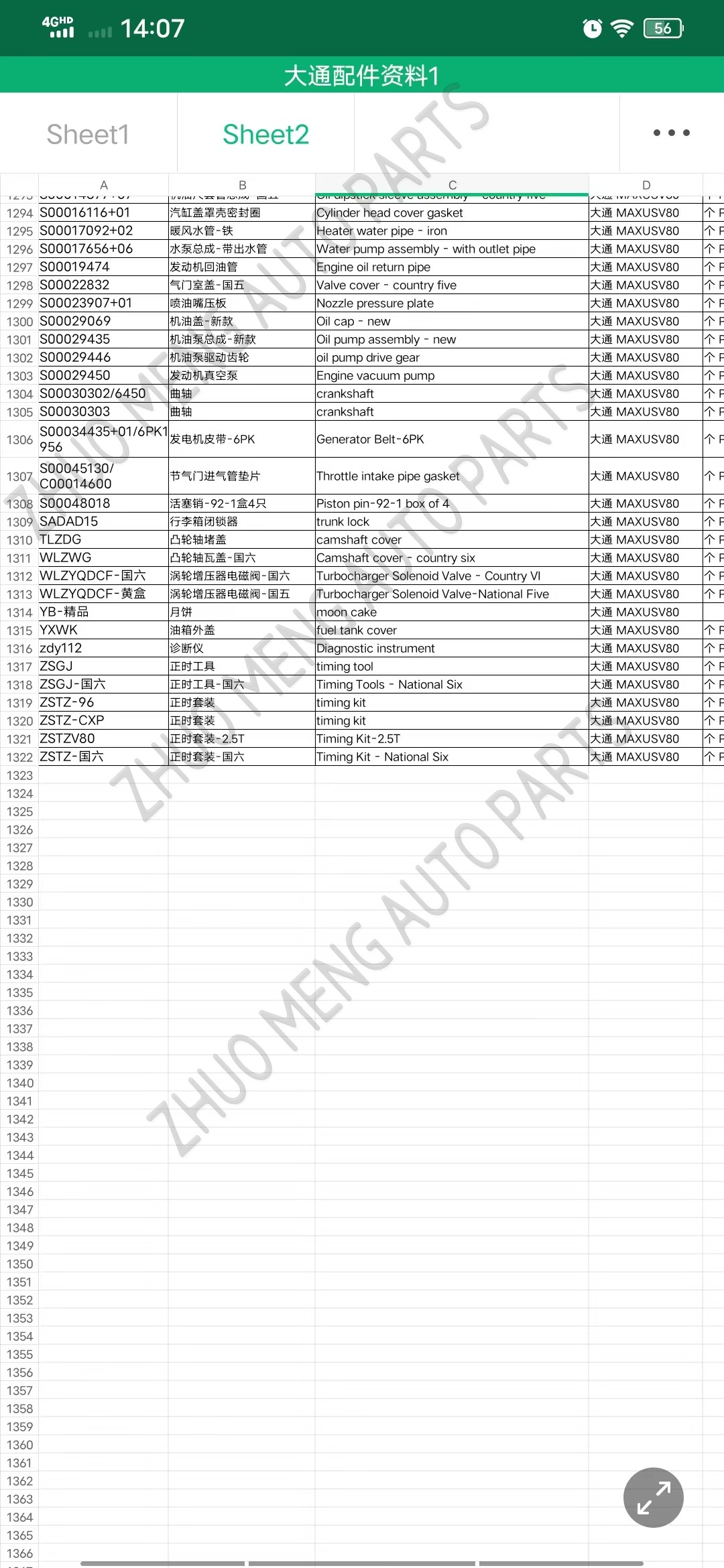

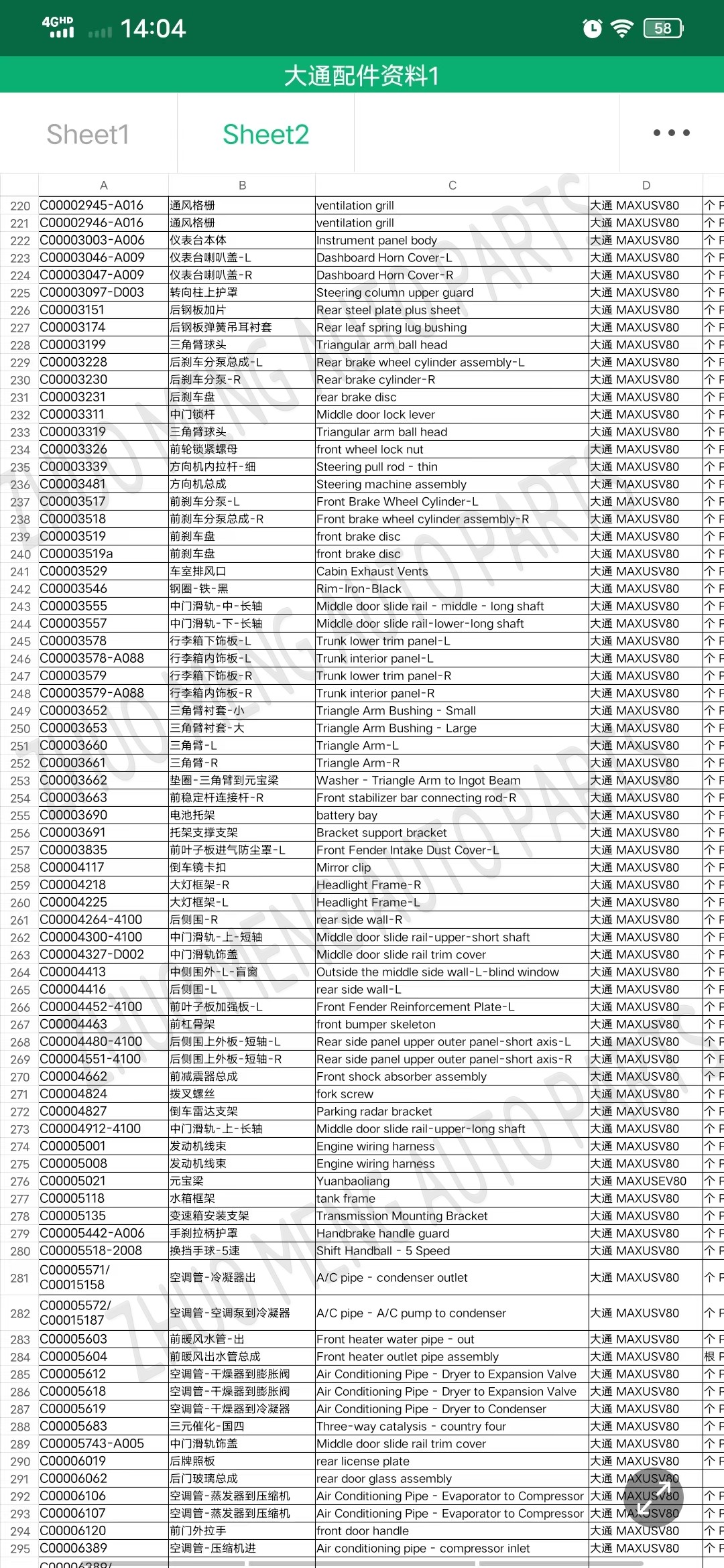

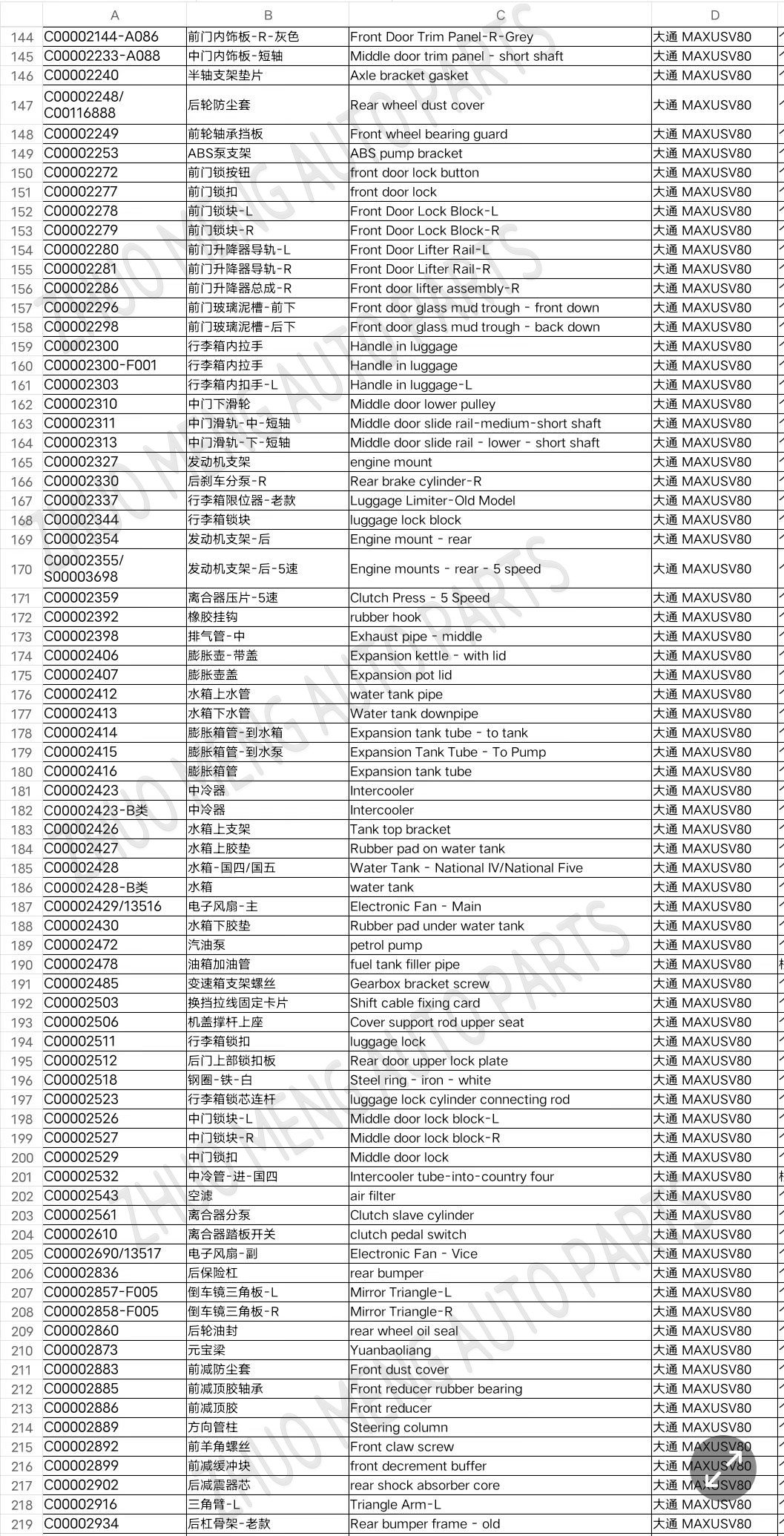

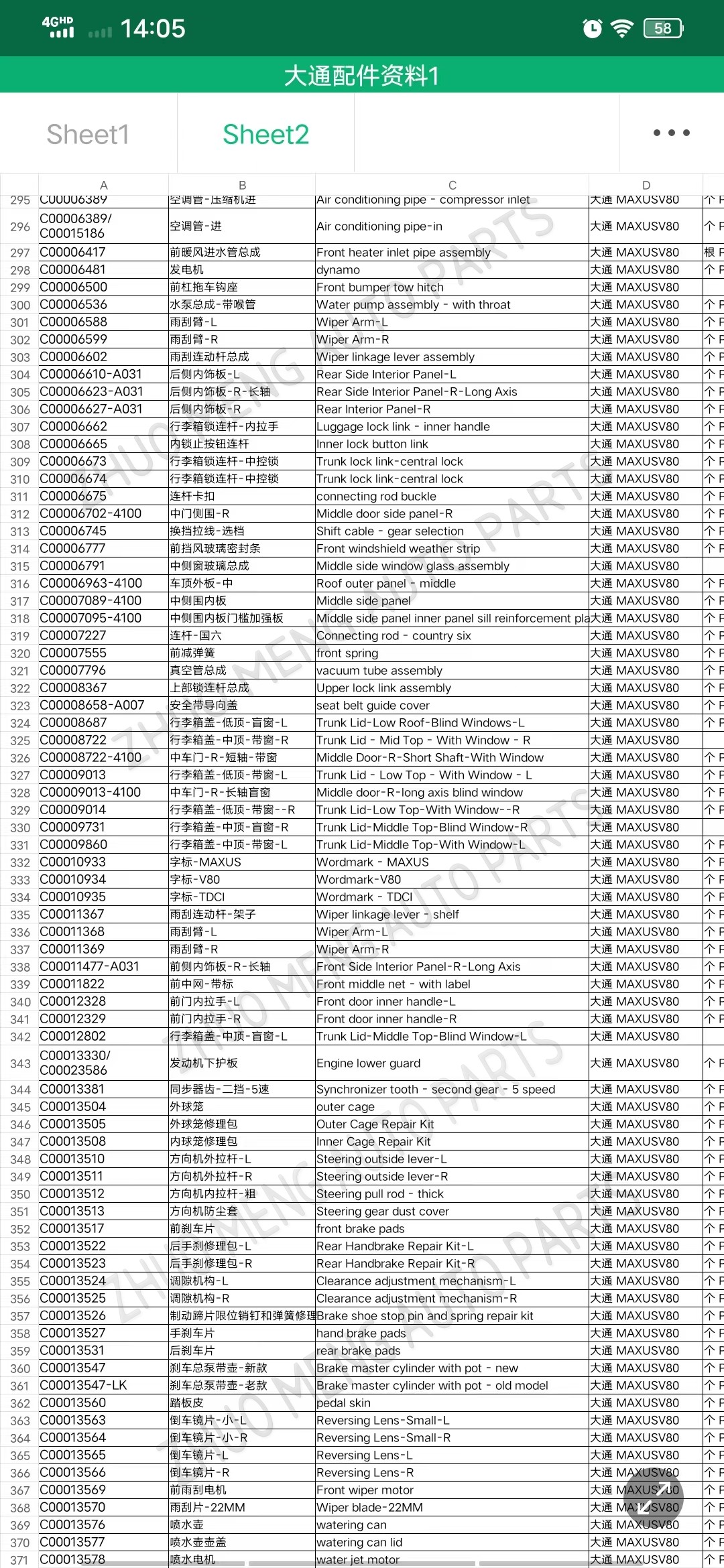

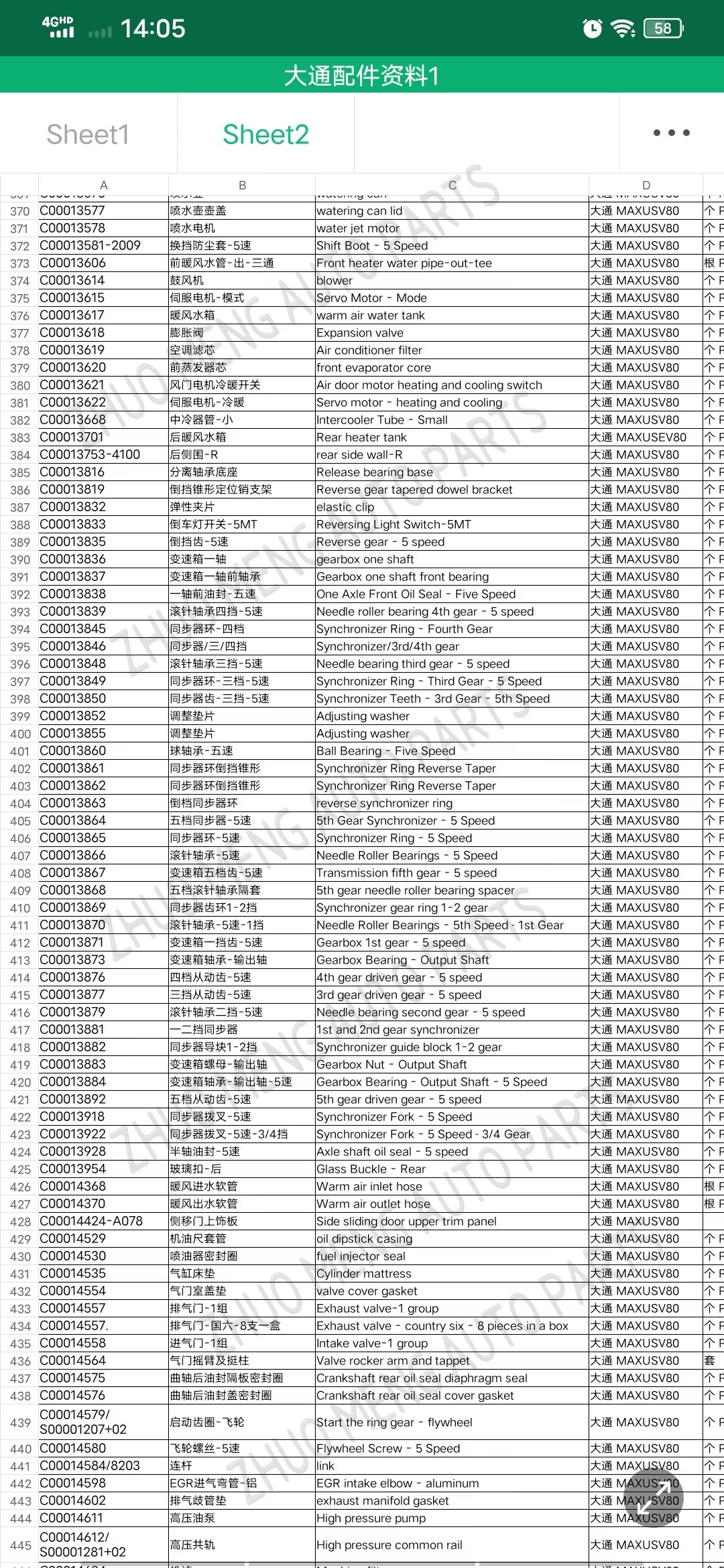

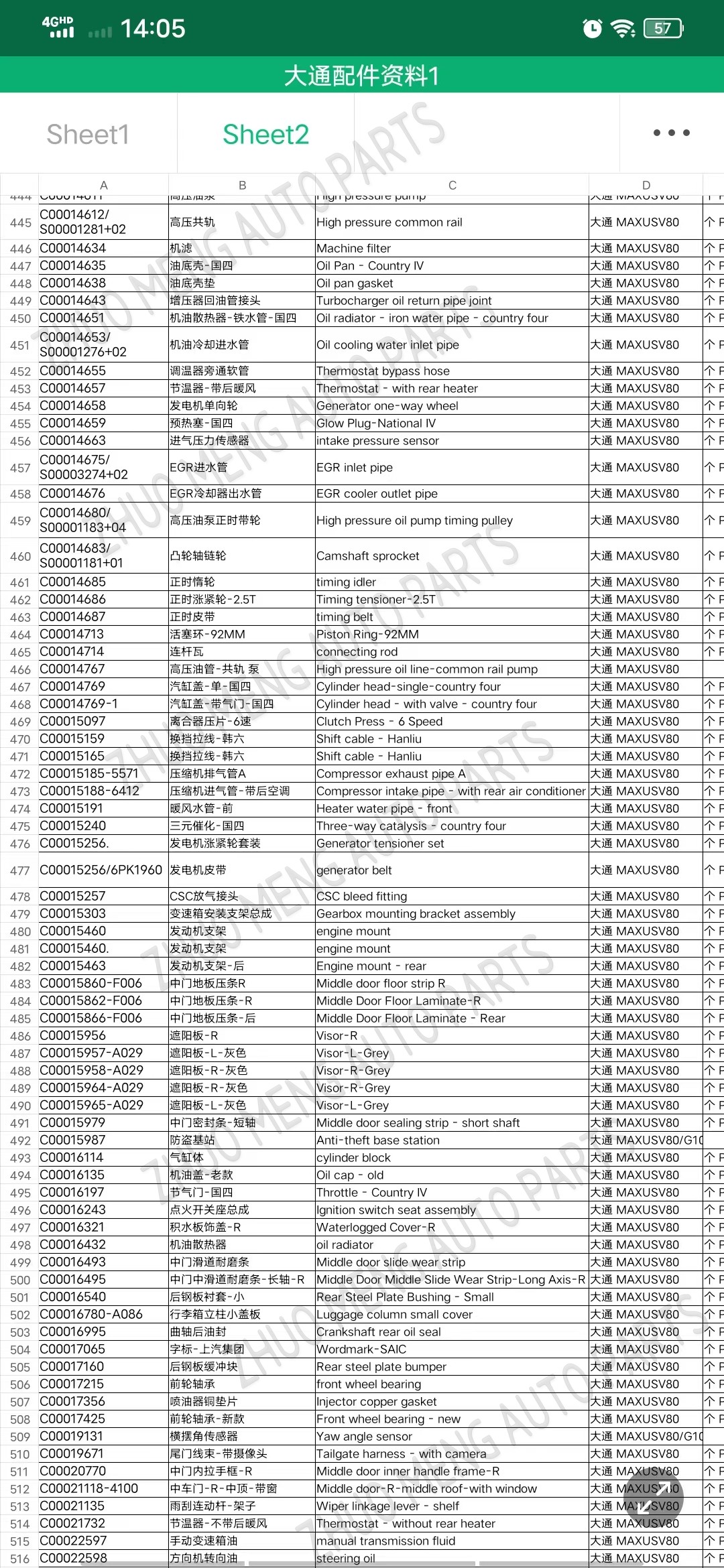

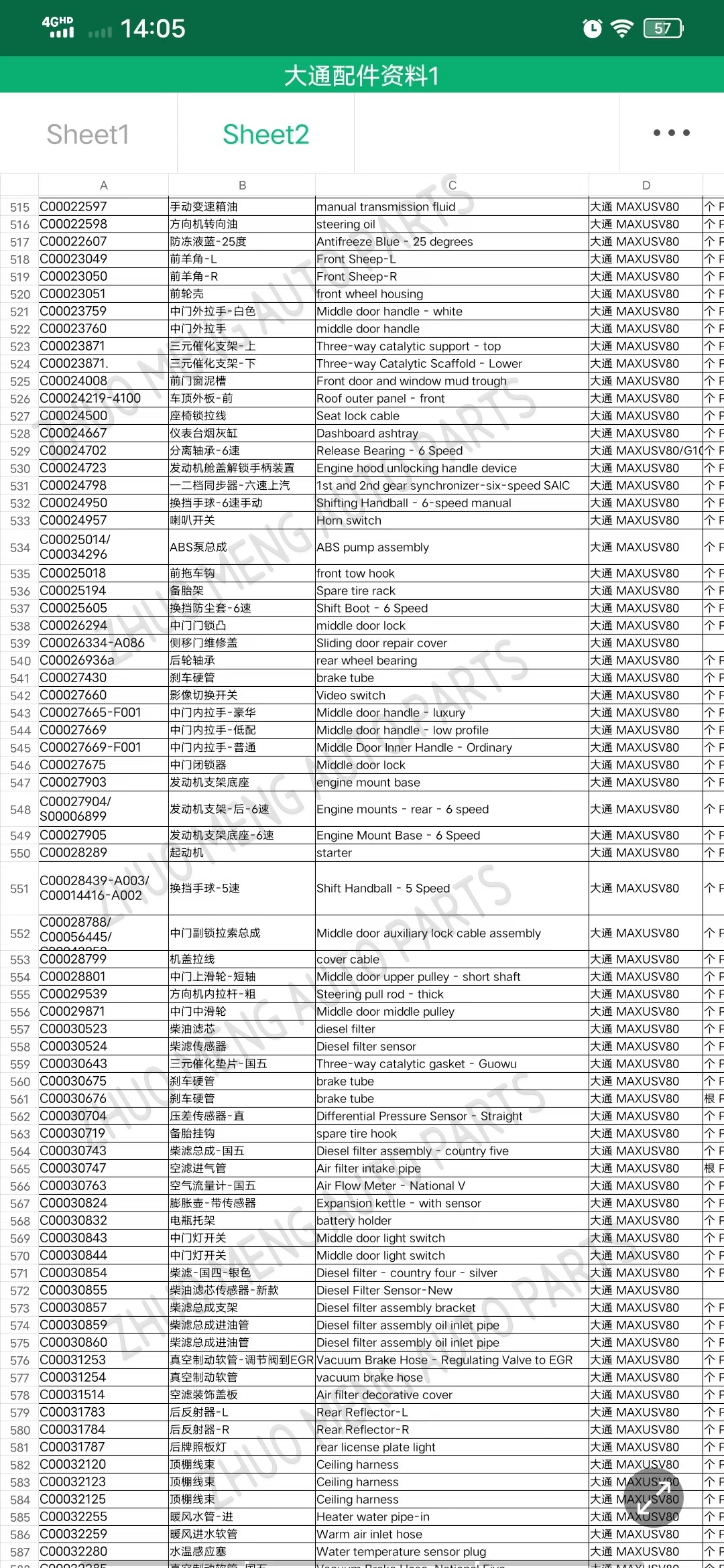

PRODUCTS CATALOG

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for China Manufacturer for Mgrx8 Spare Parts Manufacture - Factory direct sell SAIC MAXUS V80 C00014713 Piston Ring-92MM – Zhuomeng , The product will supply to all over the world, such as: Poland, Oslo, Barcelona, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!