Bottom price Mgrx8 Spare Parts Supplier - factory price SAIC MAXUS V80 front brake pads C00013157 – Zhuomeng

Bottom price Mgrx8 Spare Parts Supplier - factory price SAIC MAXUS V80 front brake pads C00013157 – Zhuomeng Detail:

Products information

| Products name | front brake pads |

| Products application | SAIC MAXUS V80 |

| Products OEM NO | C00013157 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Chassis system |

Products knowledge

Brake pads are also called brake pads. In the braking system of a car, the brake pad is the most critical safety part, and the brake pad plays a decisive role in the quality of all braking effects, so it is said that a good brake pad is the protector of people and cars.

Brake pads are generally composed of steel plates, adhesive insulation layers and friction blocks. The steel plates are coated to prevent rust. During the coating process, the SMT-4 furnace temperature tracker is used to detect the temperature distribution during the coating process to ensure the quality. The thermal insulation layer is composed of materials that do not transfer heat, and the purpose is to insulate. The friction block is composed of friction materials and adhesives. When braking, it is squeezed on the brake disc or brake drum to generate friction, so as to achieve the purpose of decelerating and braking the vehicle. Due to friction, the friction pads will gradually wear out. Generally speaking, the lower the cost of the brake pads, the faster they will be worn.

Car brake pads are divided into types: – brake pads for disc brakes – brake shoes for drum brakes – to pads for large trucks

Brake pads are mainly divided into the following categories: metal brake pads and carbon ceramic brake pads, of which metal brake pads are further divided into less metal brake pads and semi-metal brake pads, ceramic brake pads are classified as less metal, and carbon ceramic brake pads are Used with carbon ceramic brake discs.

Braking principle

The working principle of the brake is mainly from friction. The friction between the brake pad and the brake disc (drum) and the tire and the ground is used to convert the kinetic energy of the vehicle into the heat energy after friction and stop the car. A good and efficient braking system must be able to provide stable, sufficient and controllable braking force, and have good hydraulic transmission and heat dissipation capabilities to ensure that the force exerted by the driver from the brake pedal can be fully and effectively transmitted to the master cylinder And each sub-pump, and avoid hydraulic failure and brake recession caused by high heat.

Service life

Brake pad replacement depends on how long your shims have been in the life of your car. Generally, if you have a distance of more than 80,000 kilometers, the brake pads need to be replaced. However, if you hear rubbing noises from your wheels, no matter what your mileage, you should replace your brake pads. If you’re not sure how many kilometers you’ve driven, you might go to a store that replaces pads for free, buy brake pads from them or go to a car service to have them installed.

Maintenance method

1. Under normal driving conditions, check the brake shoes every 5,000 kilometers, not only to check the remaining thickness, but also to check the wear state of the shoes, whether the degree of wear on both sides is the same, whether the return is free, etc., and it is found that it is abnormal The situation must be dealt with immediately.

2. The brake shoe is generally composed of two parts: an iron lining plate and a friction material. Be sure not to wait for the friction material to wear out before replacing the shoe. For example, the front brake shoe of the Jetta has a new thickness of 14 mm, while the maximum thickness of the replacement is 7 mm, including the thickness of the iron lining plate of more than 3 mm and the thickness of the friction material of nearly 4 mm. Some vehicles have a brake shoe alarm function. Once the wear limit is reached, the meter will alarm to prompt to replace the shoe. The shoe that has reached the limit of use must be replaced. Even if it can still be used for a period of time, it will reduce the effect of braking and affect the safety of driving.

3. When replacing, replace the brake pads provided by the original spare parts. Only in this way can the braking effect between the brake pads and the brake disc be the best and the wear and tear is minimized.

4. When replacing the shoe, the brake cylinder must be pushed back with a special tool. Do not use other crowbars to press back hard, which will easily bend the guide screws of the brake caliper and cause the brake pads to be stuck.

5. After the replacement, be sure to step on the brakes a few times to eliminate the gap between the shoe and the brake disc, resulting in no brake on the first foot, which is prone to accidents.

6. After the brake shoe is replaced, it needs to be run in for 200 kilometers to achieve the best braking effect. The newly replaced shoe must be driven carefully.

How to replace brake pads:

1. Release the handbrake, and loosen the hub screw of the wheel that needs to be replaced (note that it is loosened, not completely unscrewed). Jack up the car. Then remove the tire. Before applying the brakes, it is best to spray the brake system with a special brake cleaning fluid to prevent the powder from entering the respiratory tract and affecting health.

2. Unscrew the brake caliper (for some cars, just unscrew one of them, then loosen the other one)

3. Hang the brake caliper with a rope to avoid damage to the brake pipeline. Then remove the old brake pads.

4. Use the c-clamp to push the brake piston all the way back. (Please note that before this step, lift the hood and unscrew the cover of the brake fluid box, because the fluid level of the brake fluid will rise when the brake piston is pushed up). Install new brake pads.

5. Reinstall the brake caliper and tighten the caliper screw to the required torque. Put the tire back on and tighten the hub screws slightly.

6. Lower the jack and fully tighten the hub screws.

7. Because in the process of changing the brake pads, we pushed the brake piston to the innermost side, and it will be very empty when you first step on the brake. After a few steps in a row, it will be fine.

Inspection Method

1. Look at the thickness: The thickness of a new brake pad is generally about 1.5cm, and the thickness will gradually become thinner with the continuous friction in use. When the thickness of the brake pads is observed with the naked eye, only about 1/3 of the original thickness (about 0.5cm) is left. The owner will increase the frequency of self-inspection and be ready to replace it at any time. Some models do not have the conditions for visual inspection due to the design of the wheel hub, and the tires need to be removed to complete.

If it is the latter, wait until the warning light is on, and the metal base of the brake pad and the brake disc are already in a state of iron grinding. At this time, you will see bright iron chips near the edge of the rim. Therefore, we recommend checking the wear condition of the brake pads regularly to see if they can be used, rather than just trusting the warning lights.

2. Listen to the sound: If there is a “iron rubbing iron” sound or clamor (it may also be caused by the running-in of the brake pads at the beginning of installation) when the brake is lightly pressed, the brake pads must be installed immediately. replace.

3. By foot feel: If you feel very hard to step on, you often need to step on the brakes deeper to achieve the previous braking effect, or when you take emergency braking, you will obviously feel that the pedal position is low, then it may be that the brake pads have basically been lost. The friction is gone, and it must be replaced at this time.

Common problem

Q: How often should the brake pads be changed? A: Generally speaking, the replacement cycle of front brake pads is 30,000 kilometers, and the replacement cycle of rear brake pads is 60,000 kilometers. Different models may have slight differences.

How to prevent excessive wear?

1. In the process of continuing down steep slopes, reduce the speed of the vehicle in advance, use the appropriate gear, and use the operation mode of engine braking and braking system, which can effectively reduce the burden on the braking system and avoid the overheating of the braking system.

2. It is forbidden to extinguish the engine during the downhill process. Cars are basically equipped with a brake vacuum booster pump. Once the engine is turned off, the brake booster pump will not only fail to assist, but will also produce great resistance to the brake master cylinder, and the braking distance will be reduced. multiply.

3. When the automatic transmission car is driving in the urban area, no matter how fast it is, it is necessary to collect the oil in time. If you are very close to the car in front of you and only apply the brakes, the wear of the brake pads will be very serious, and it will also consume a lot of fuel. How to prevent excessive wear of the brakes? Therefore, when an automatic transmission vehicle sees a red light or a traffic jam ahead, it is necessary to collect fuel in advance, which not only saves fuel, but also saves maintenance costs and increases driving comfort.

4. When driving at night, when driving from a bright place to a dark place, the eyes need an adaptation process to the change of light. In order to ensure safety, the speed must be reduced. How to prevent excessive brake wear? In addition, when passing through curves, slopes, bridges, narrow roads and places that are not easy to see, you should reduce your speed and be ready to brake or stop at any time to prevent unexpected accidents and ensure Drive safely.

Precautions

Brake drums are equipped with brake shoes, but generally people call brake pads to refer to brake pads and brake shoes, so “disc brake pads” are used to specify the brake pads installed on disc brakes. Not the brake disc.

How to buy

Four Look First, look at the friction coefficient. The friction coefficient determines the basic braking torque of the brake pads. If the friction coefficient is too high, it will cause the wheels to lock, lose control of the direction and burn the disc during the braking process. If it is too low, the braking distance will be too long; Safety, the brake pads will generate instantaneous high temperature during braking, especially in high-speed driving or emergency braking, the friction coefficient of the friction pads will decrease under high temperature conditions; the third is to see if it is comfortable, including braking feeling, noise, dust, risk, etc. Smoke, odor, etc., are the direct manifestation of friction performance; four look at the service life, usually the brake pads can guarantee a service life of 30,000 kilometers.

OUR EXHIBITION

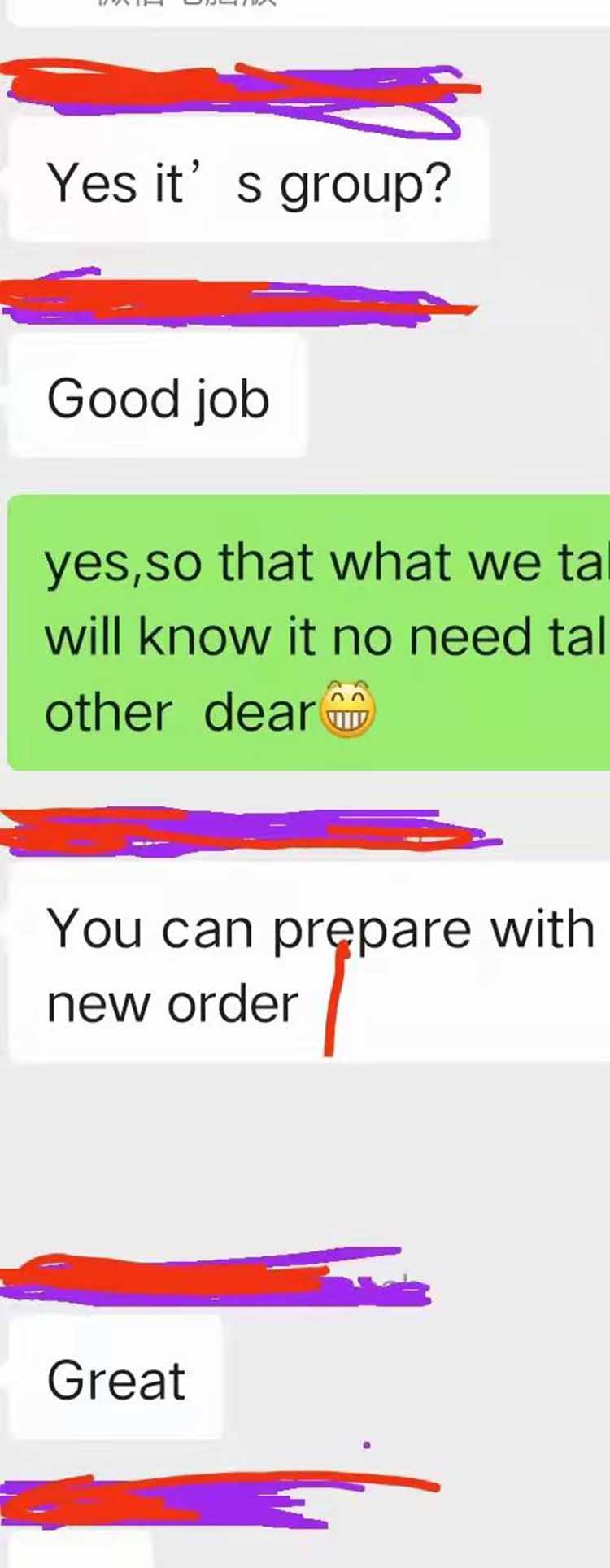

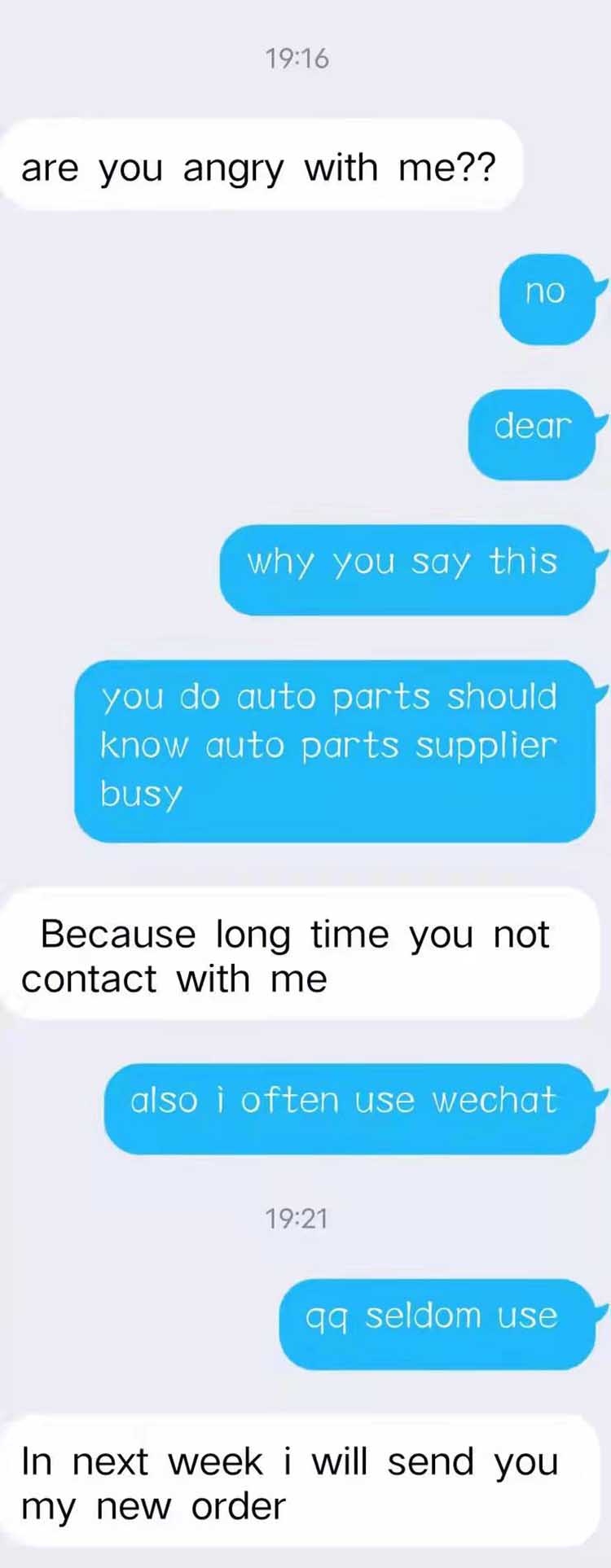

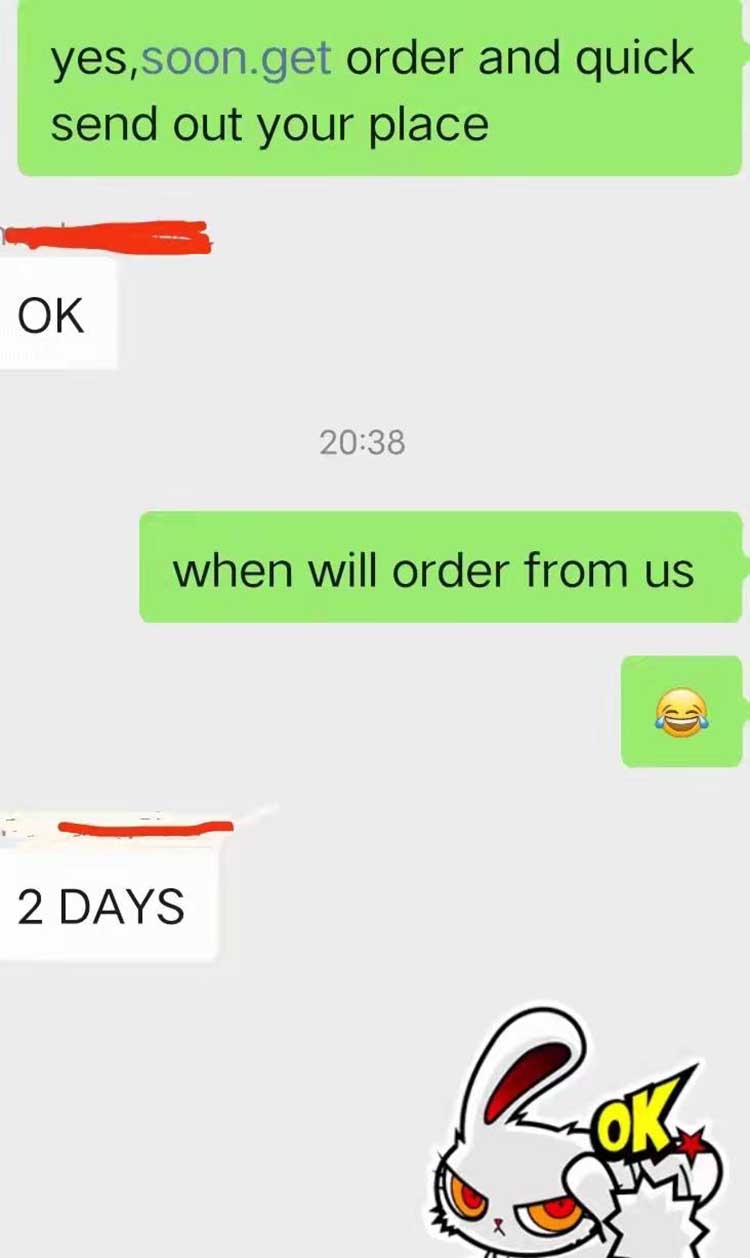

Good Feetback

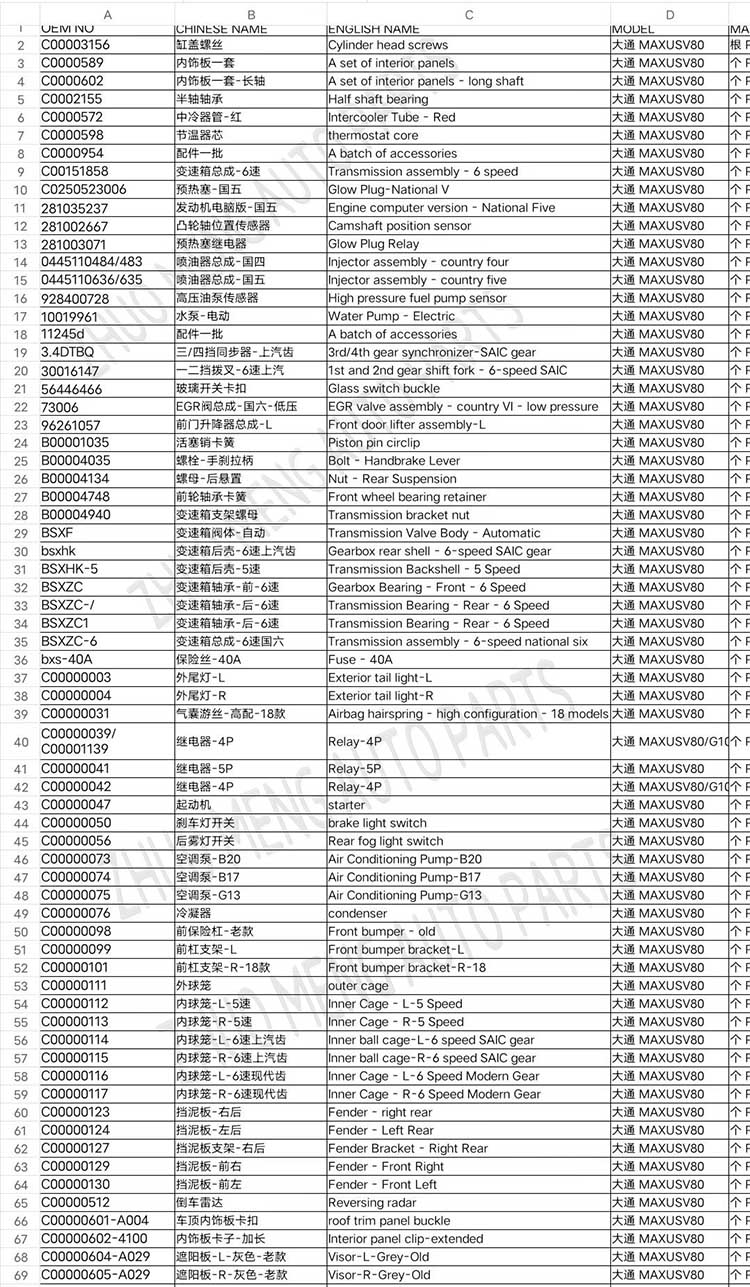

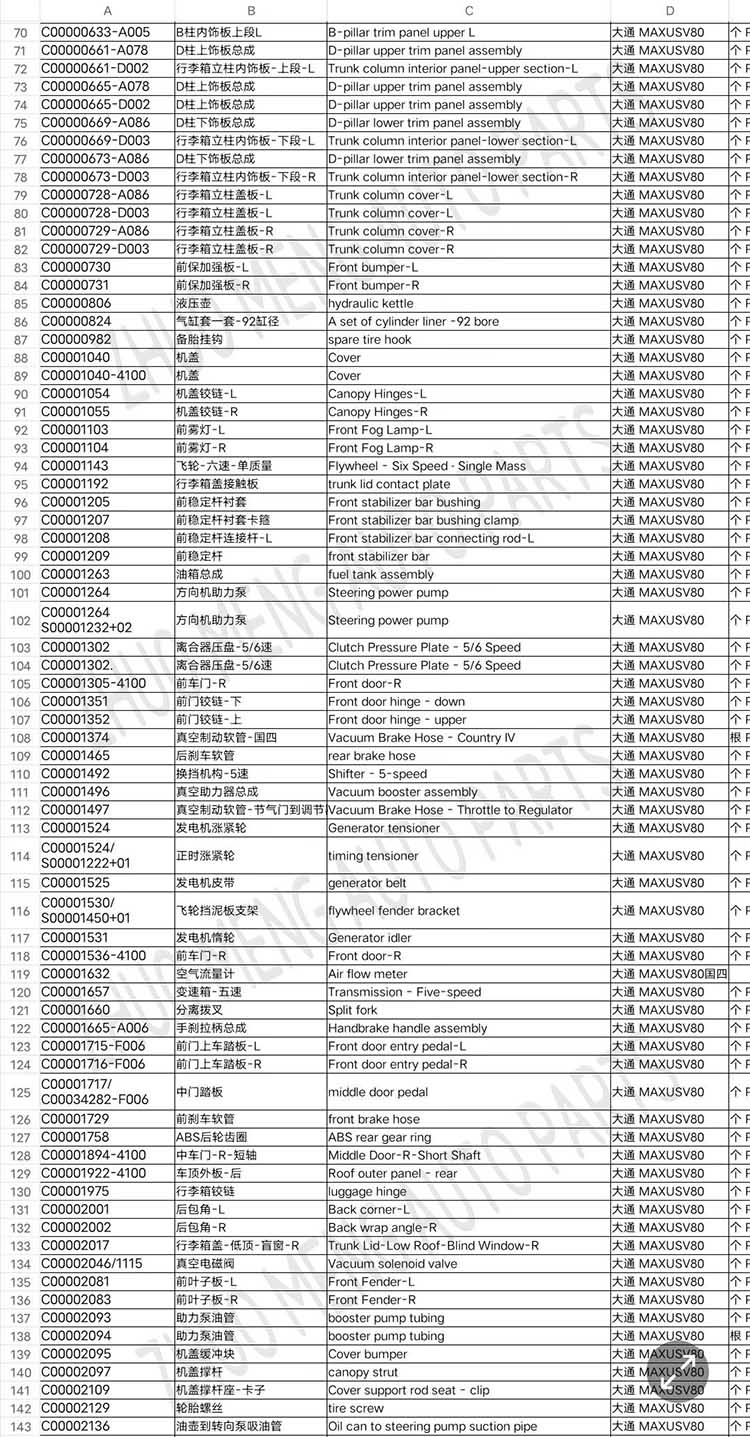

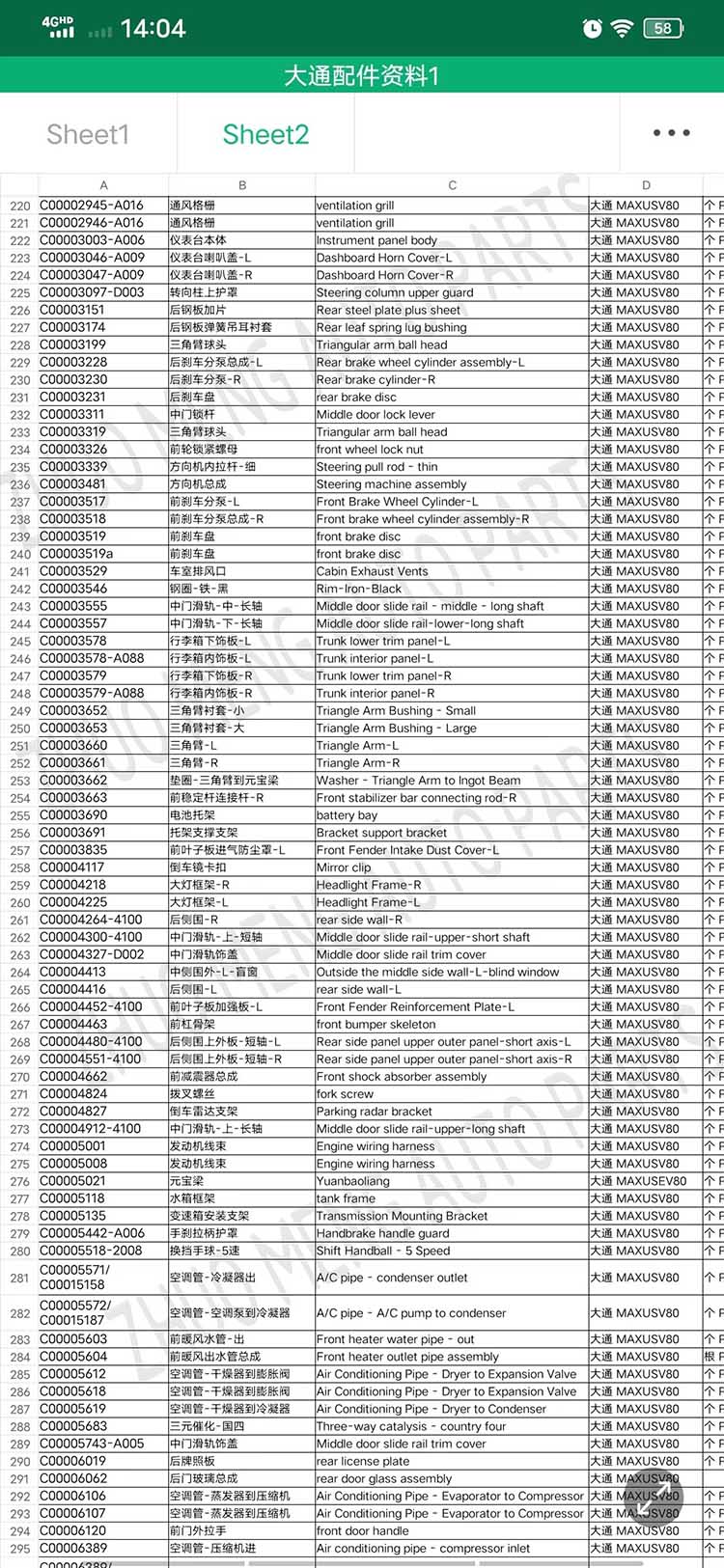

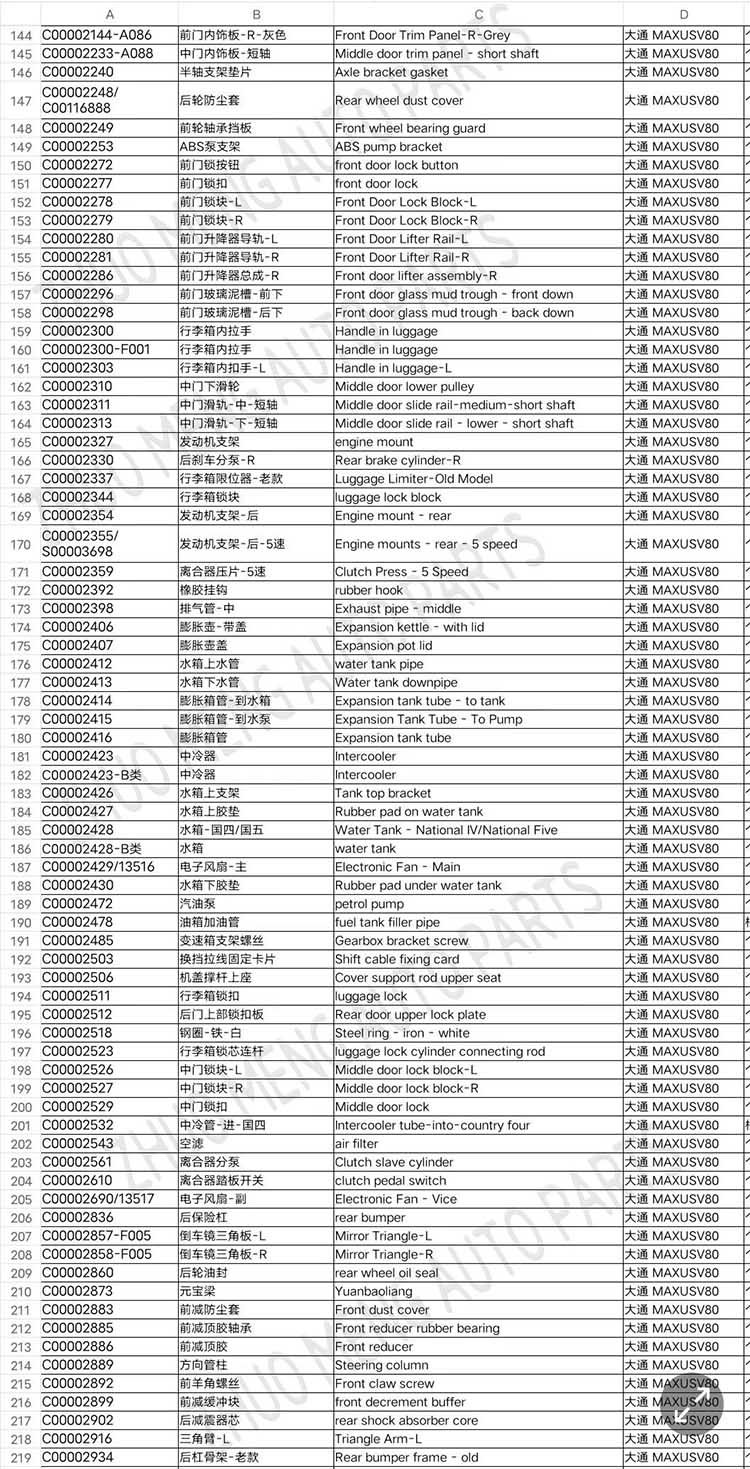

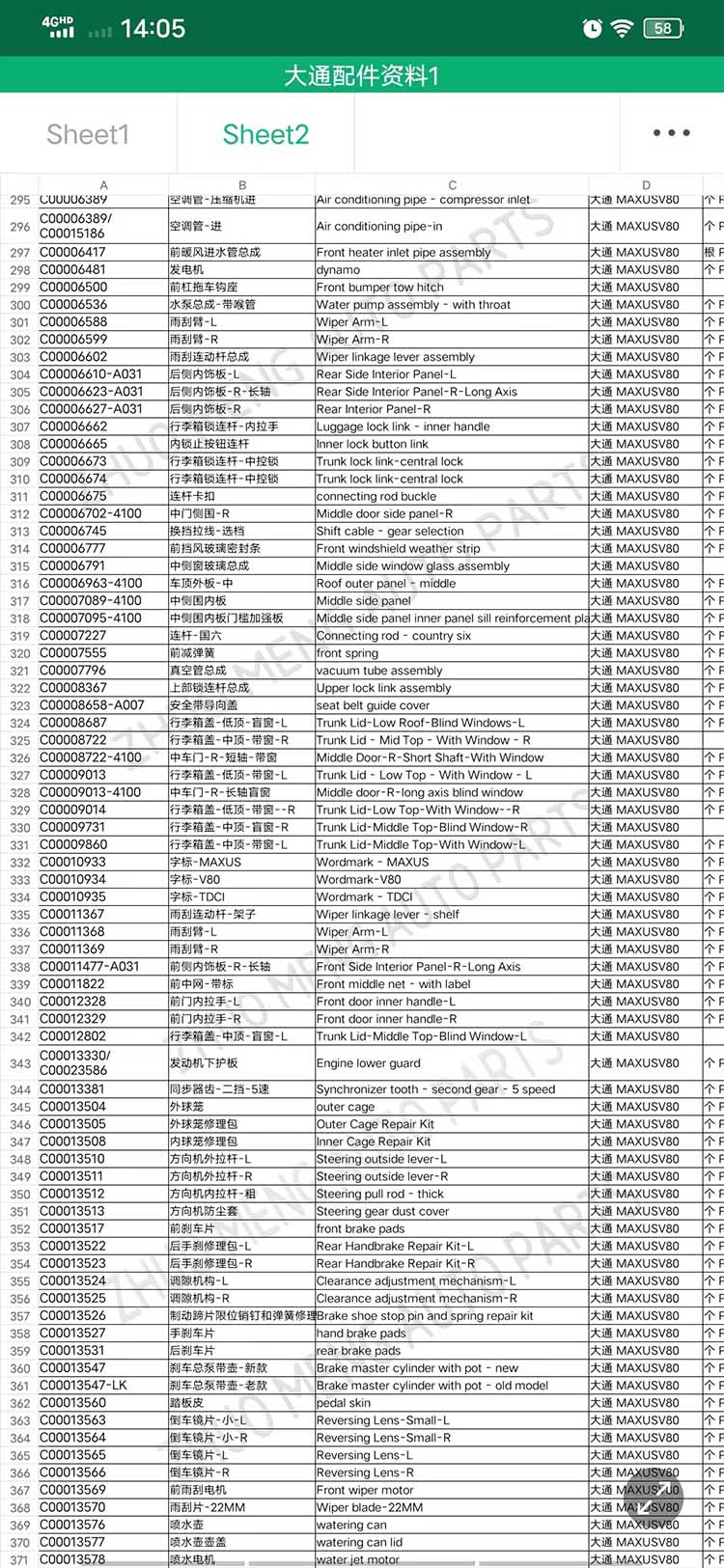

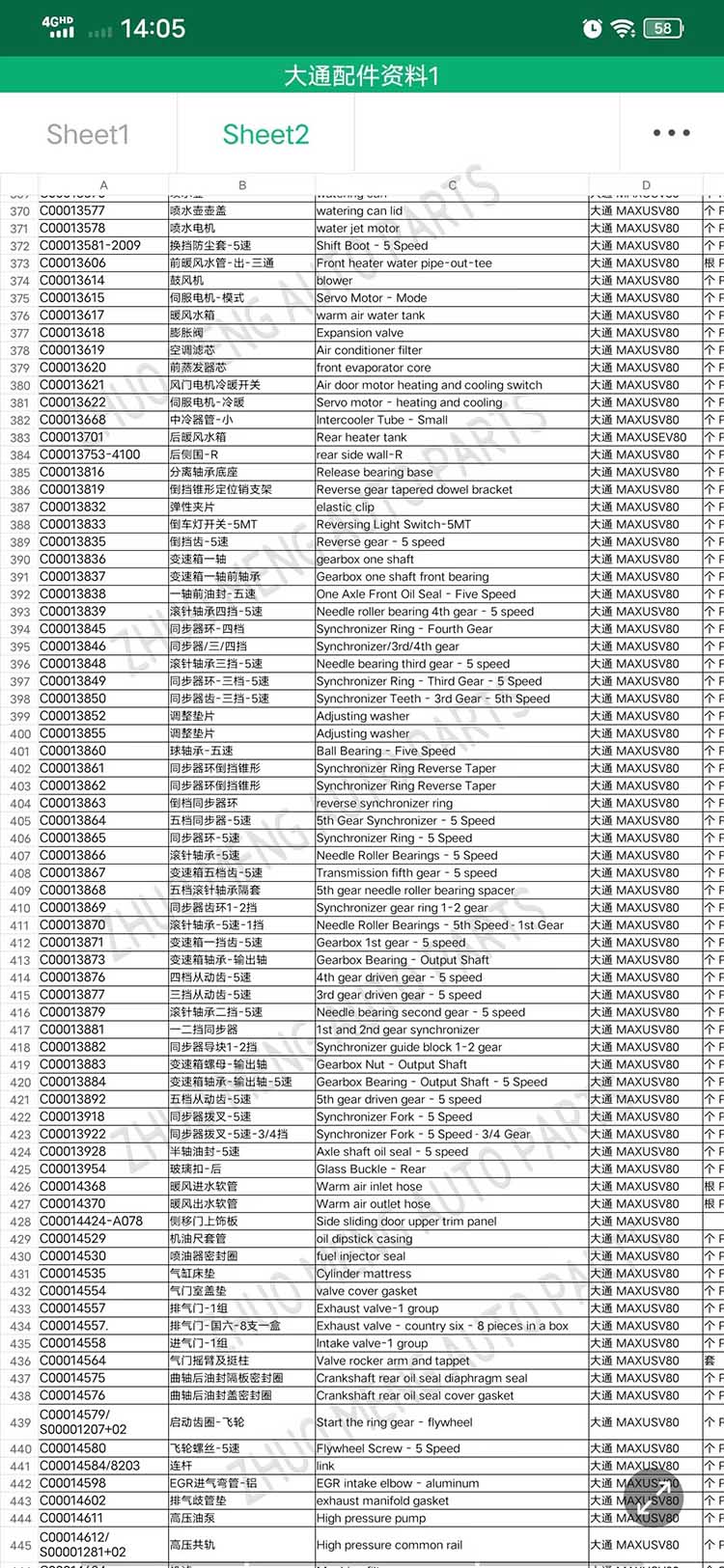

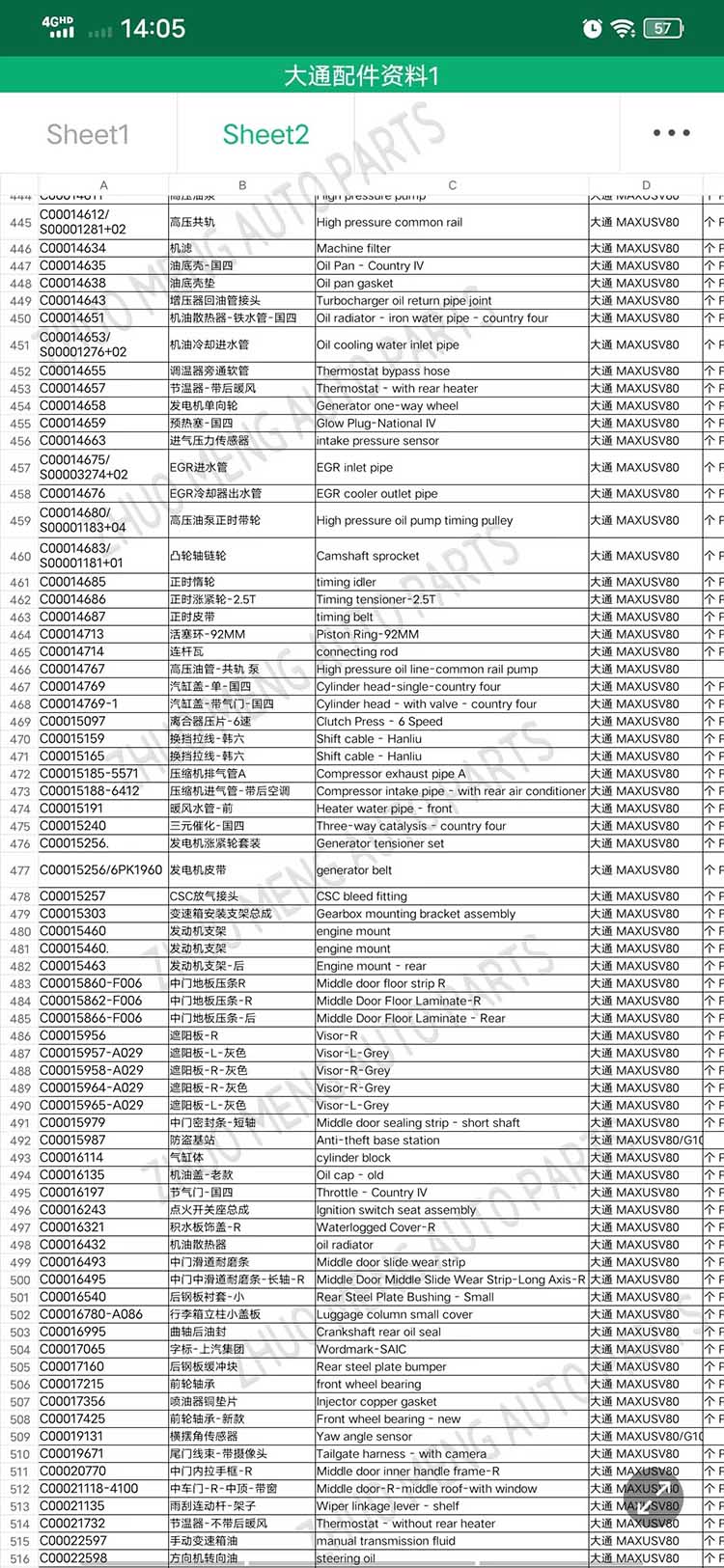

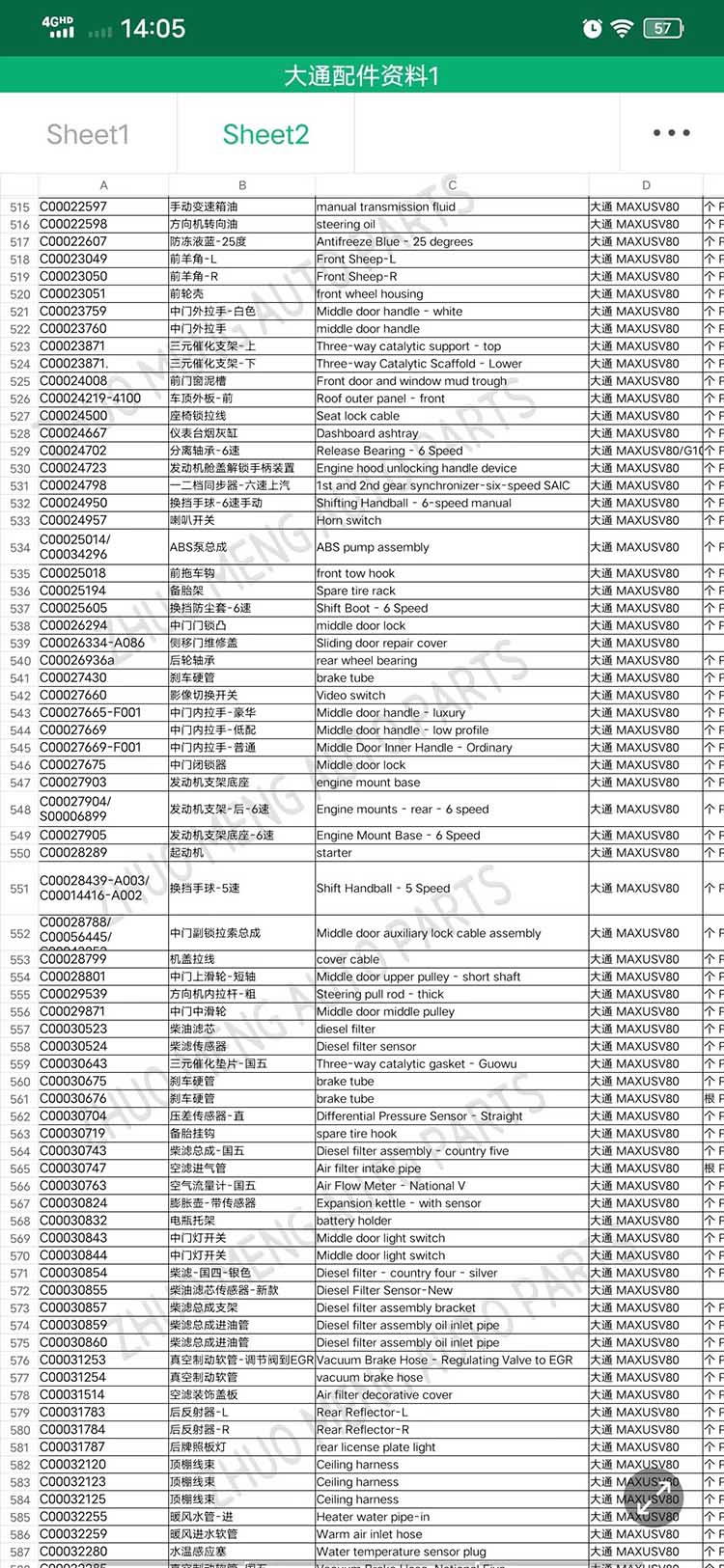

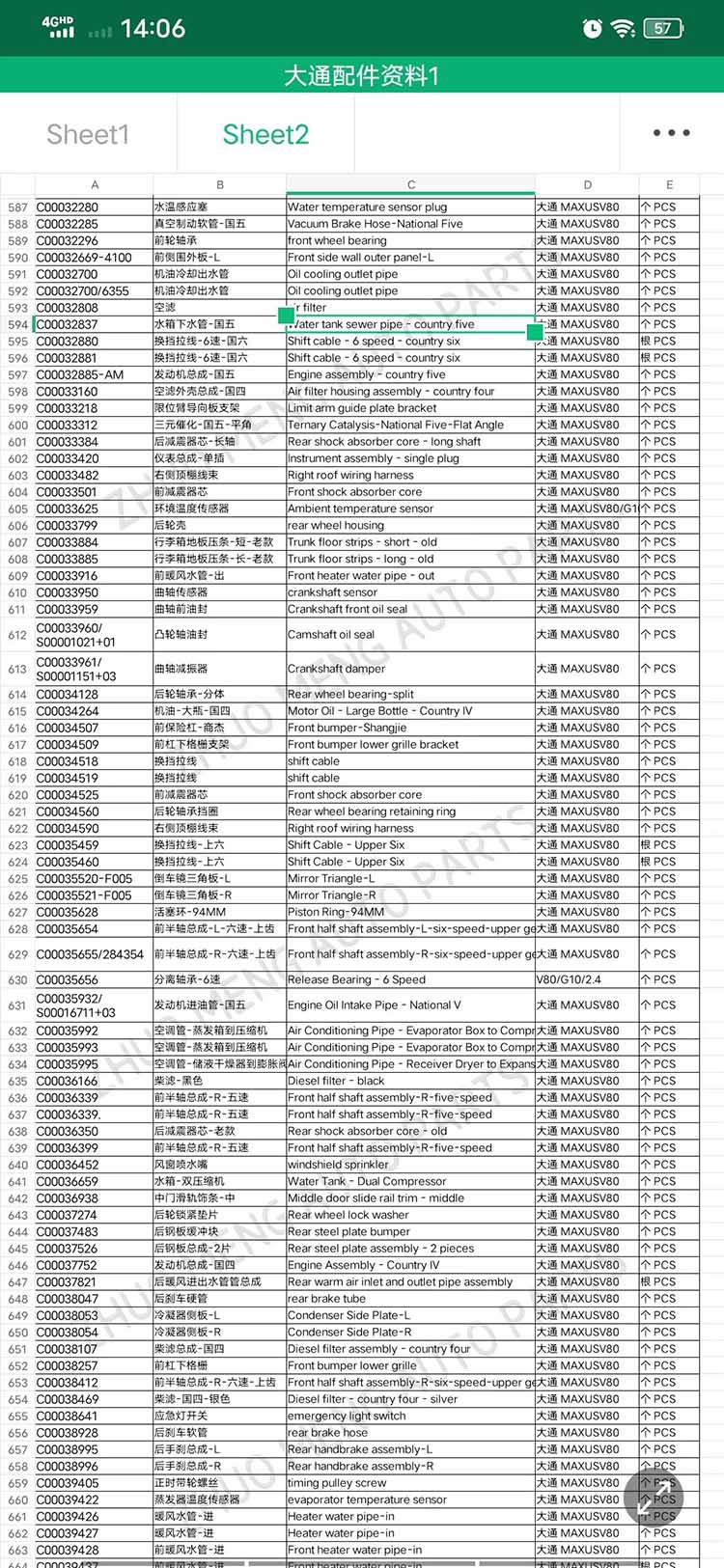

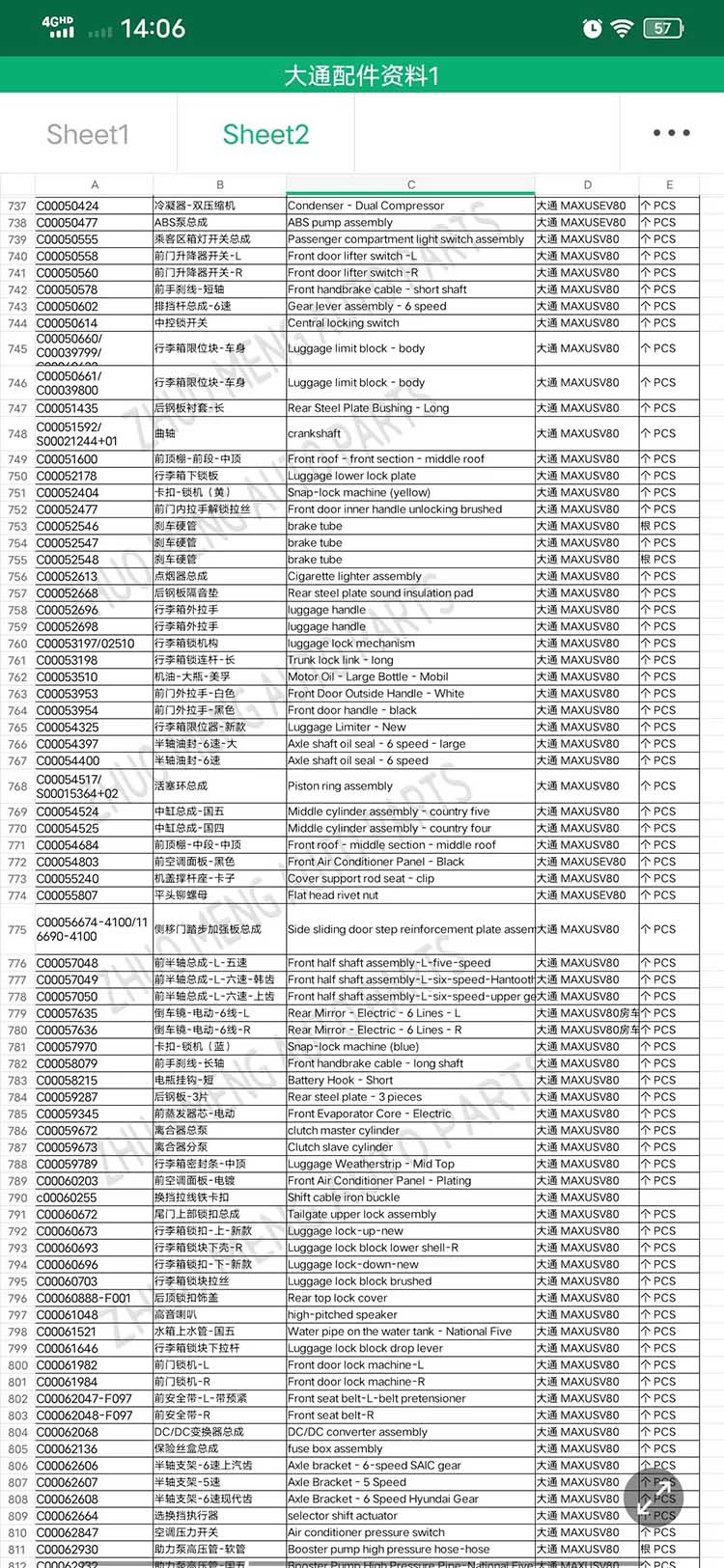

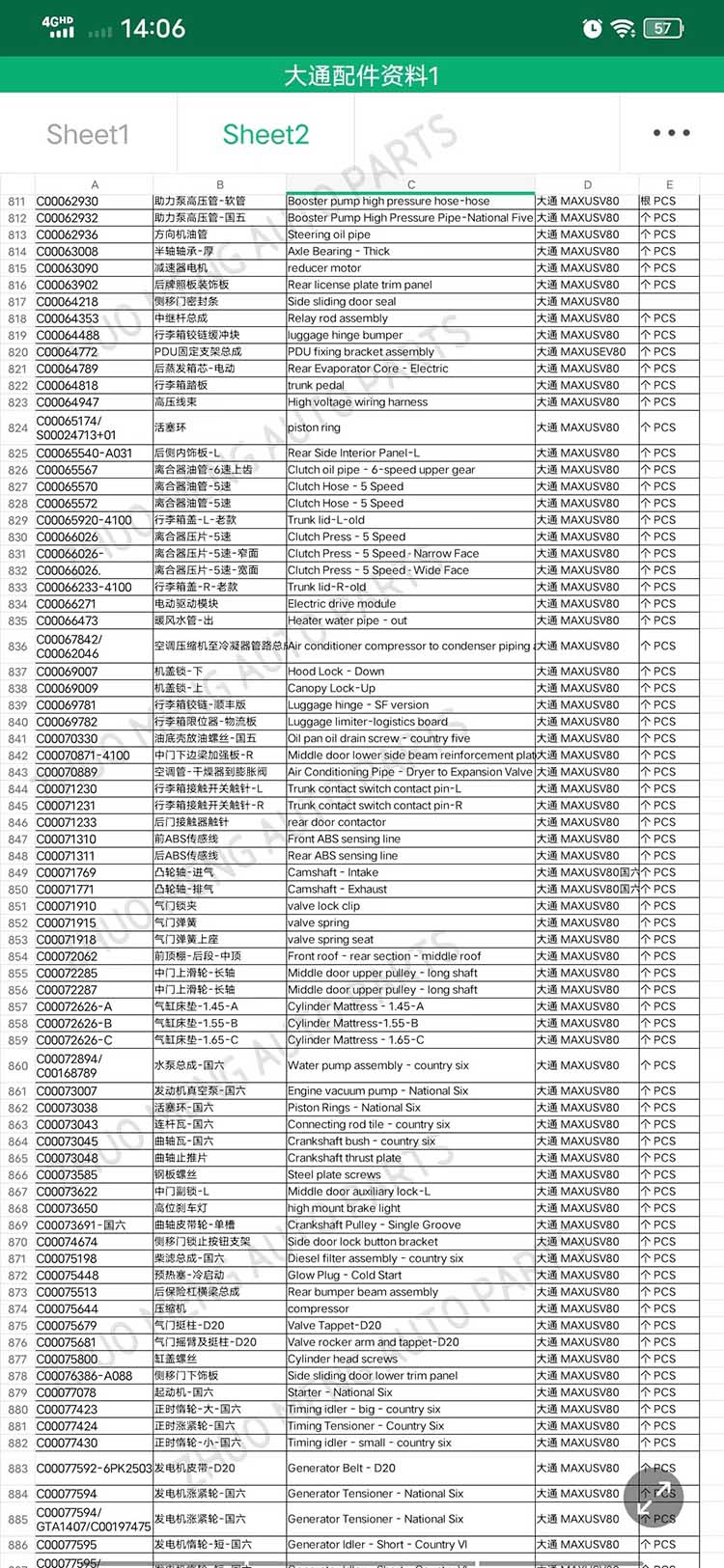

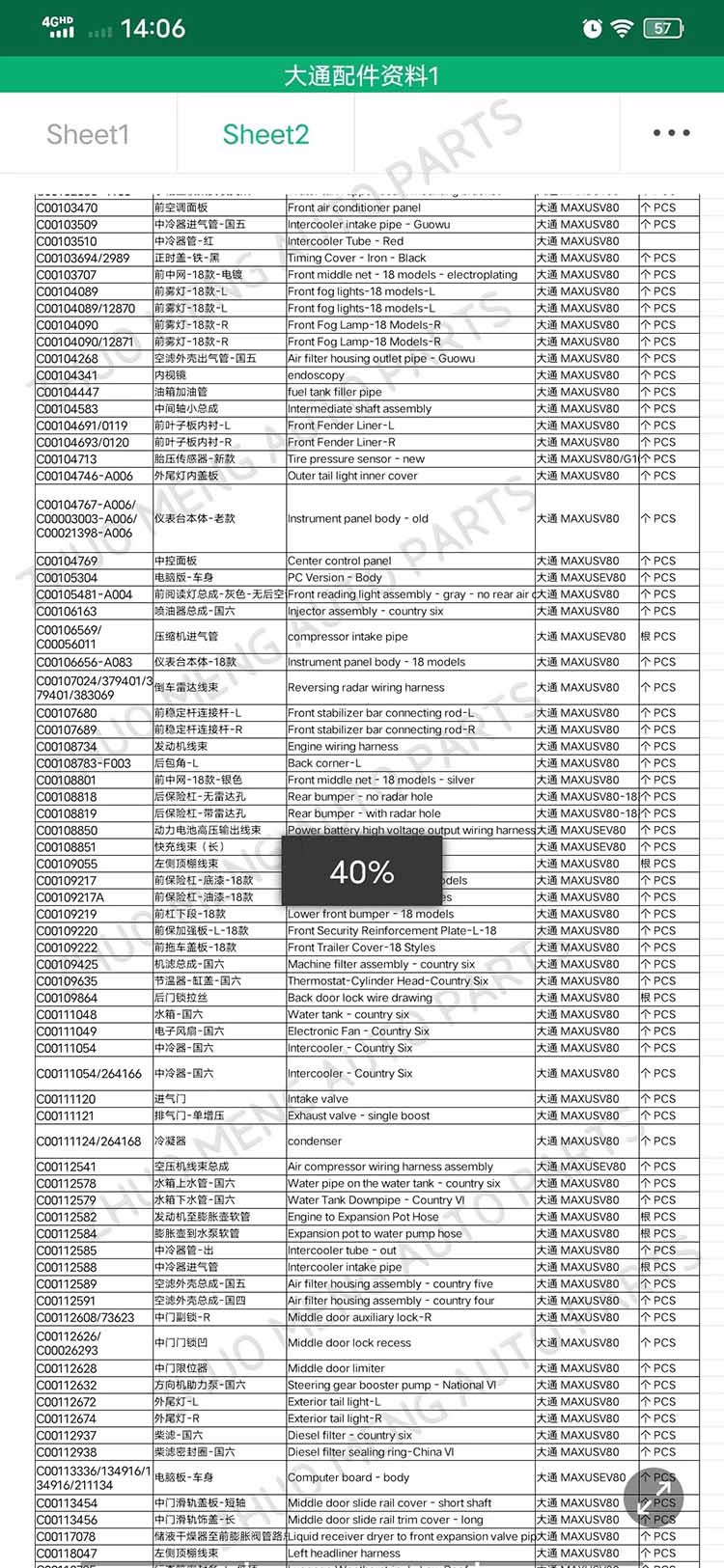

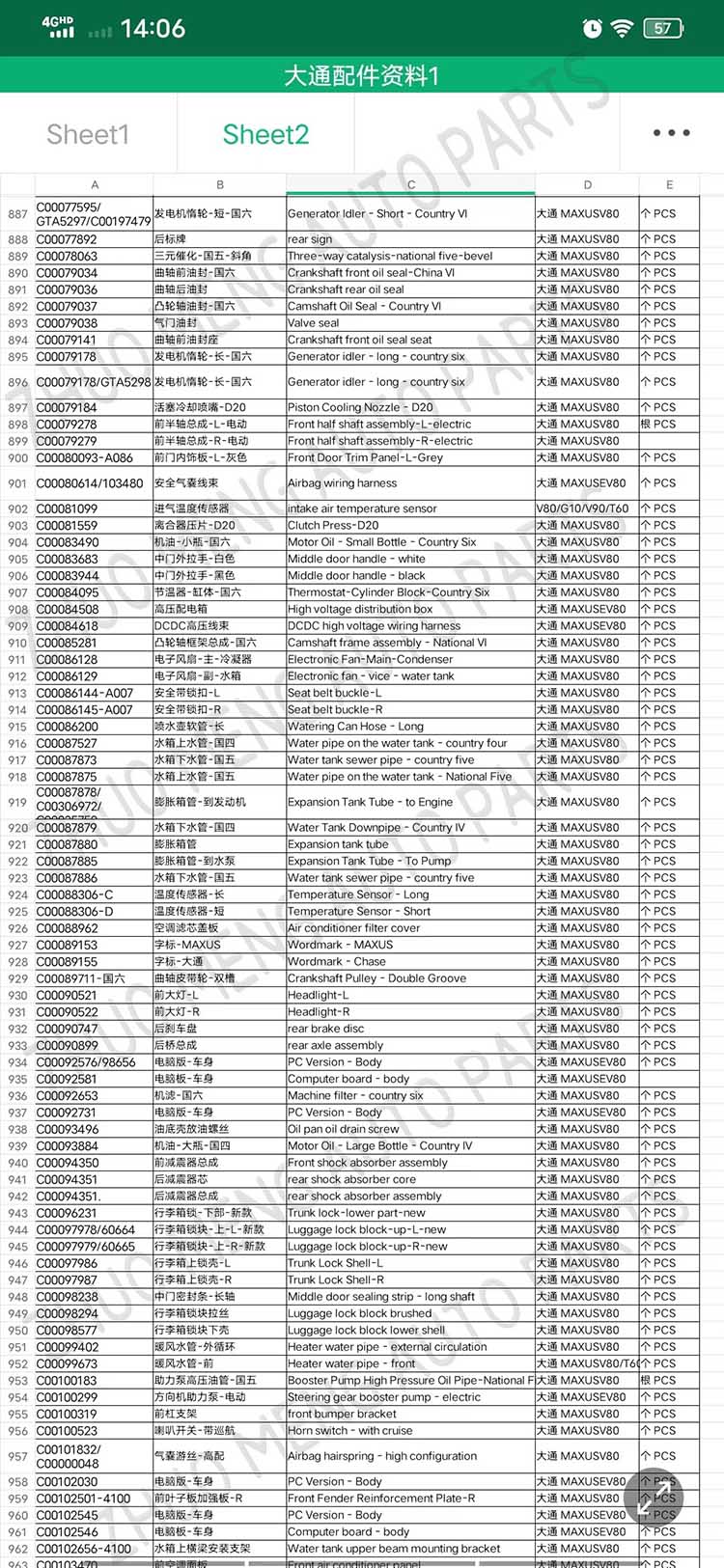

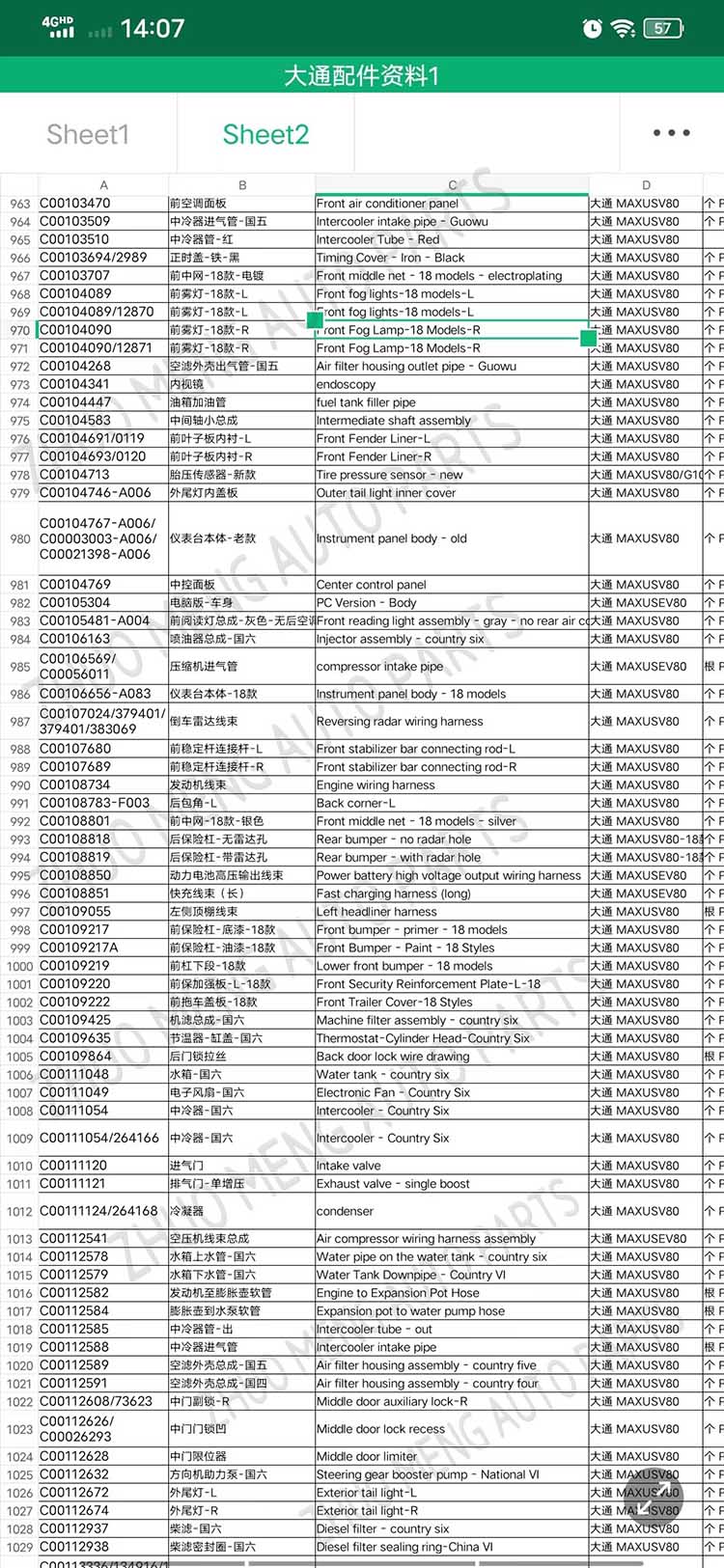

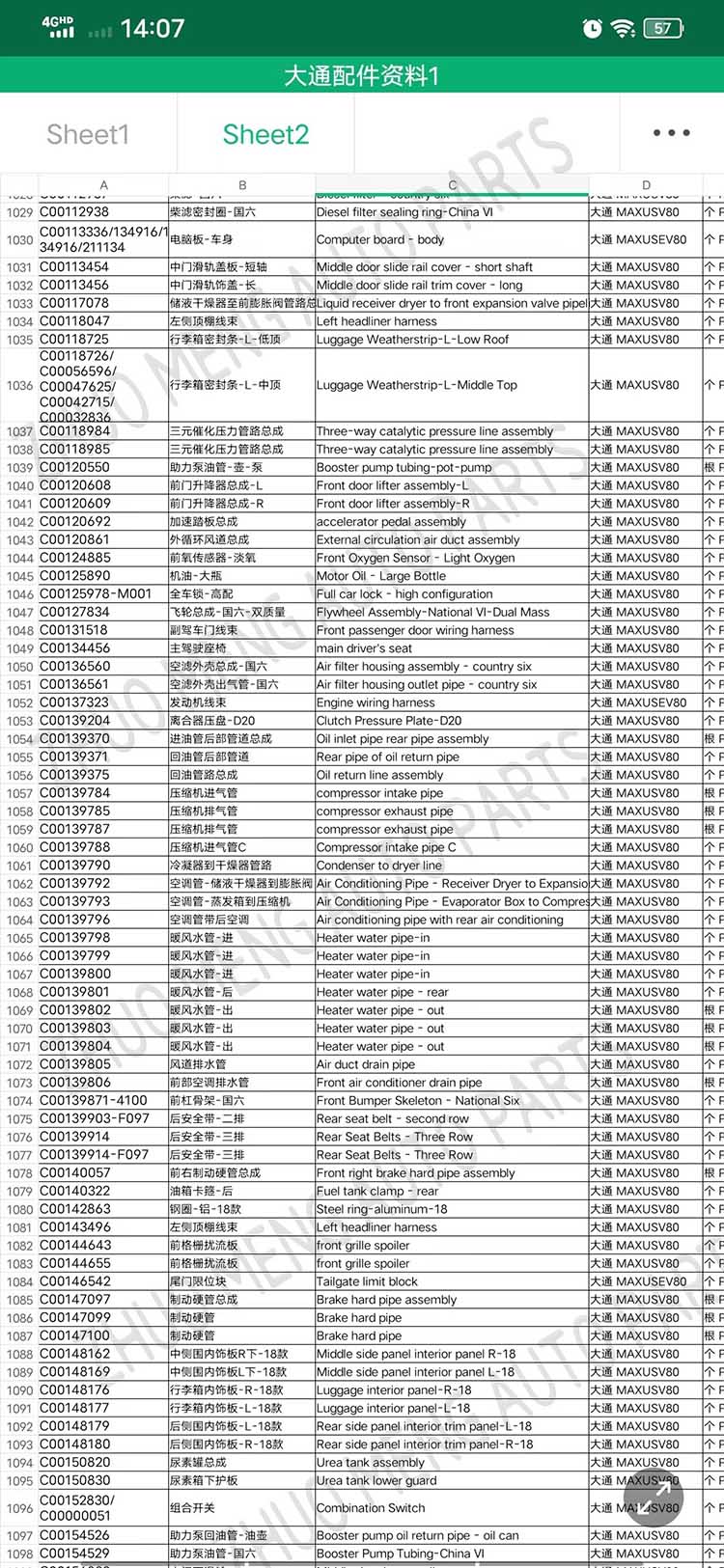

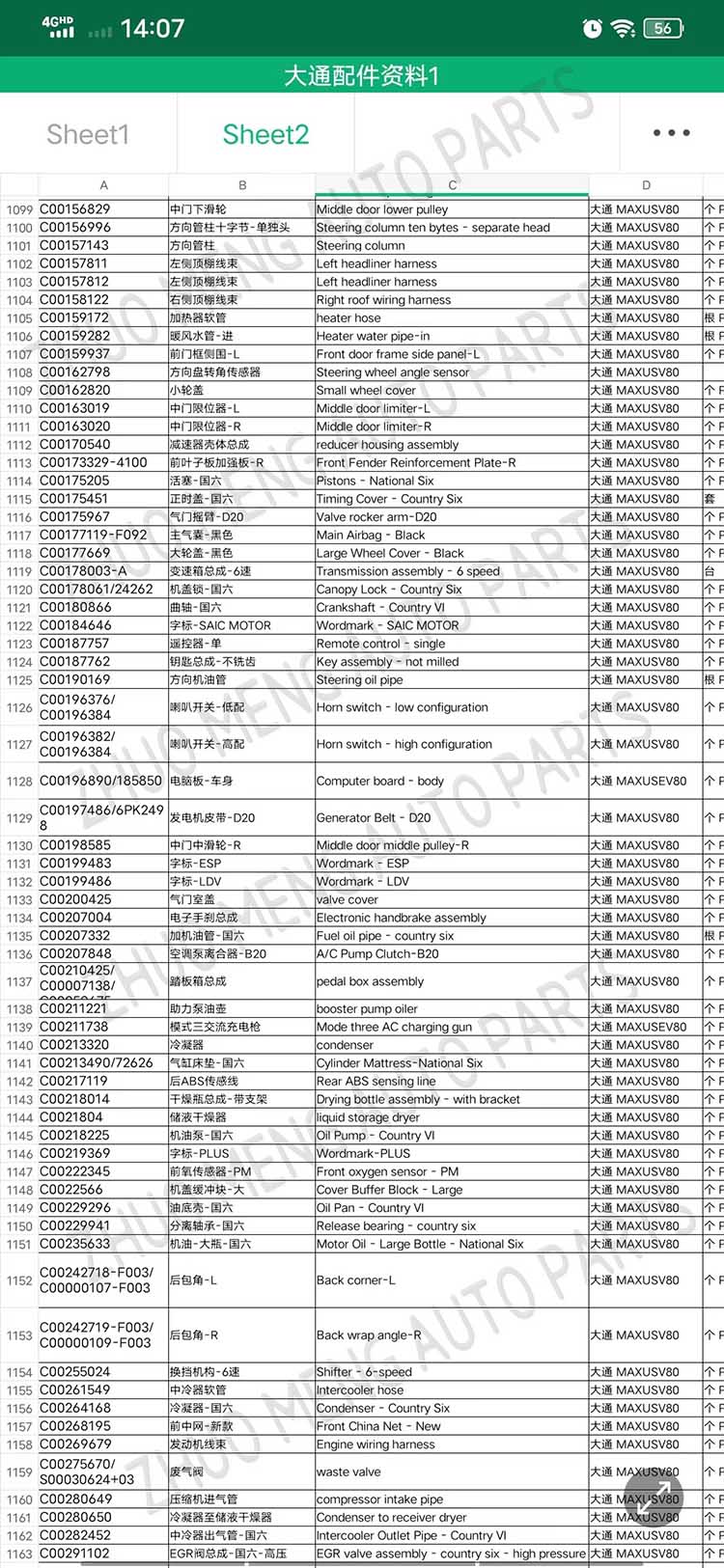

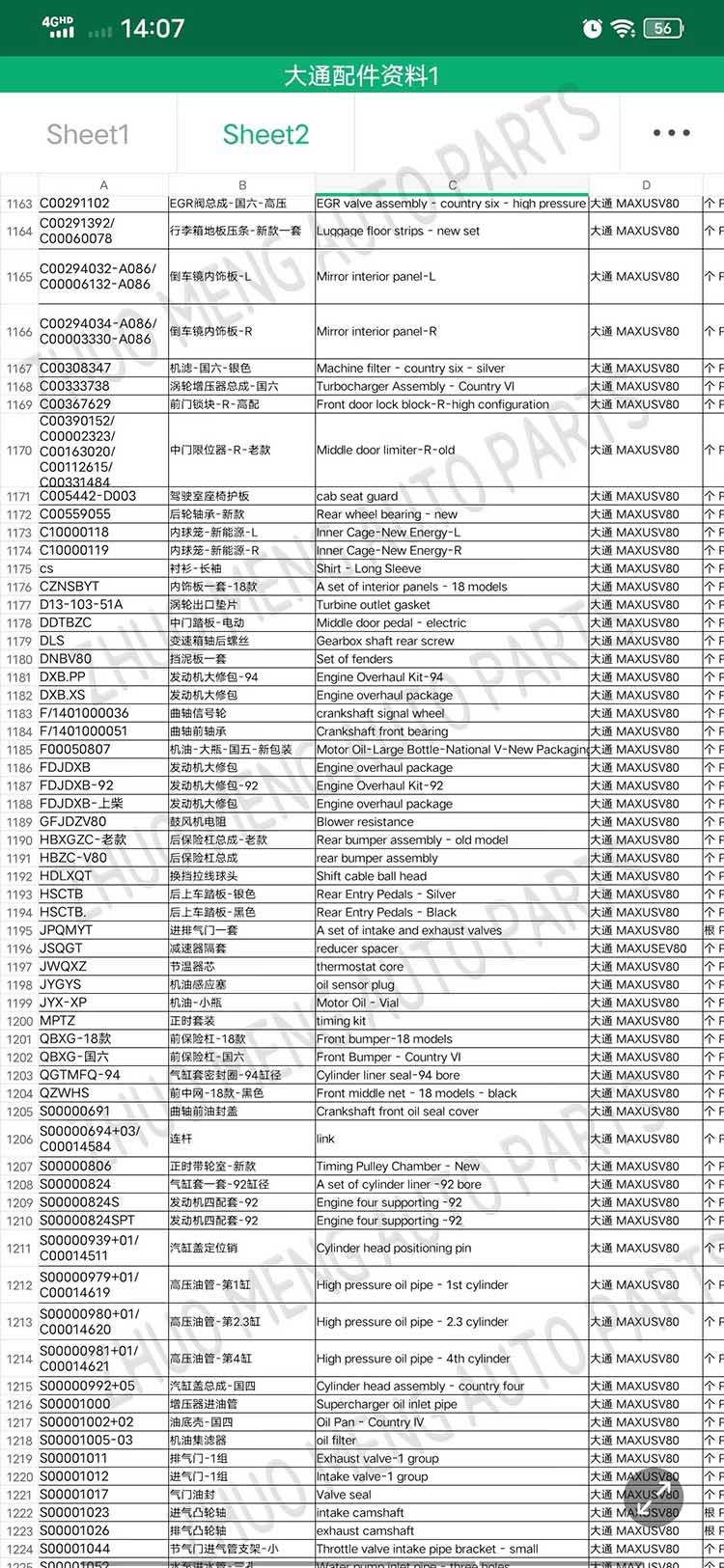

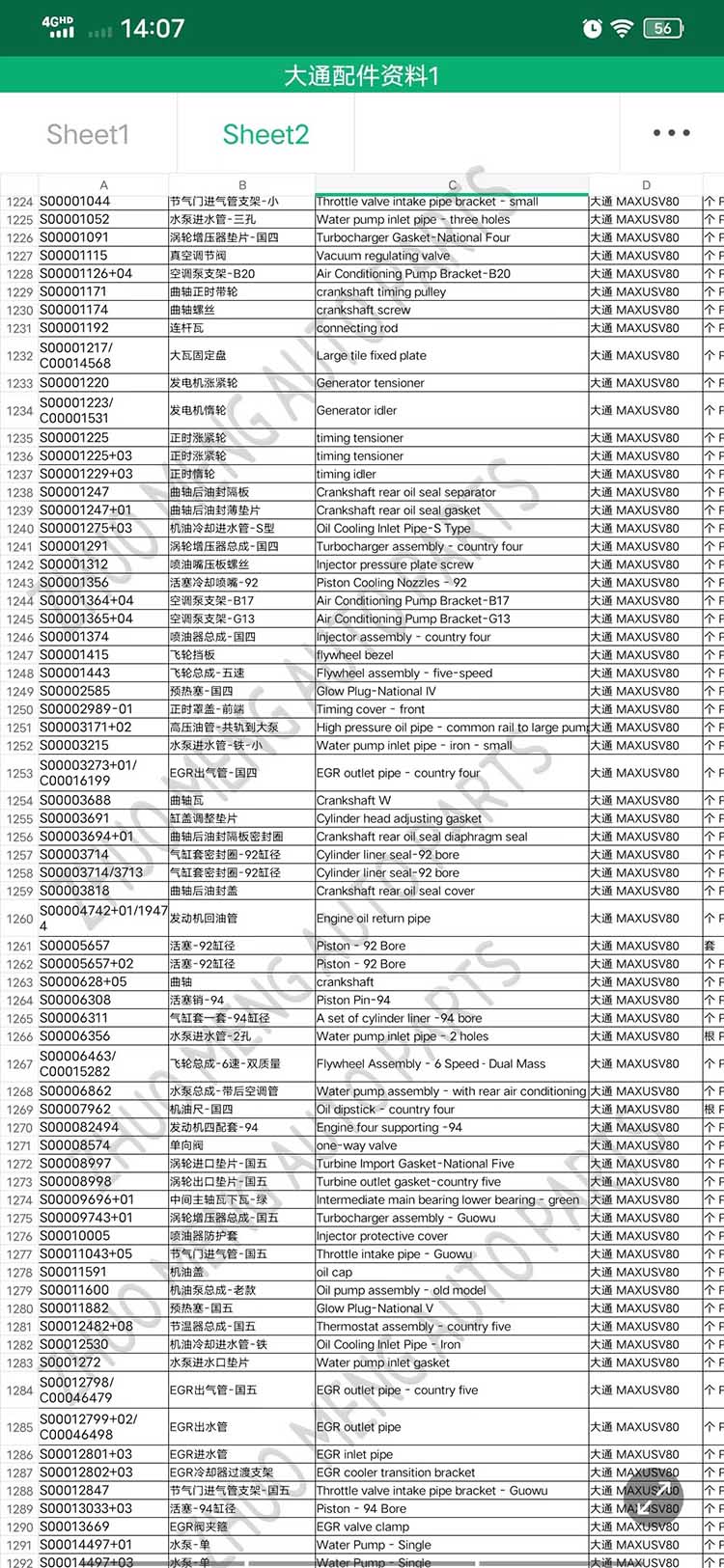

Products catalog

Related products

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Bottom price Mgrx8 Spare Parts Supplier - factory price SAIC MAXUS V80 front brake pads C00013157 – Zhuomeng , The product will supply to all over the world, such as: Uruguay, Anguilla, Estonia, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.