2022 wholesale price Mg Classic Parts - MG 550 Collection Of Various Wheel Bearings – Zhuomeng

2022 wholesale price Mg Classic Parts - MG 550 Collection Of Various Wheel Bearings – Zhuomeng Detail:

Products Information

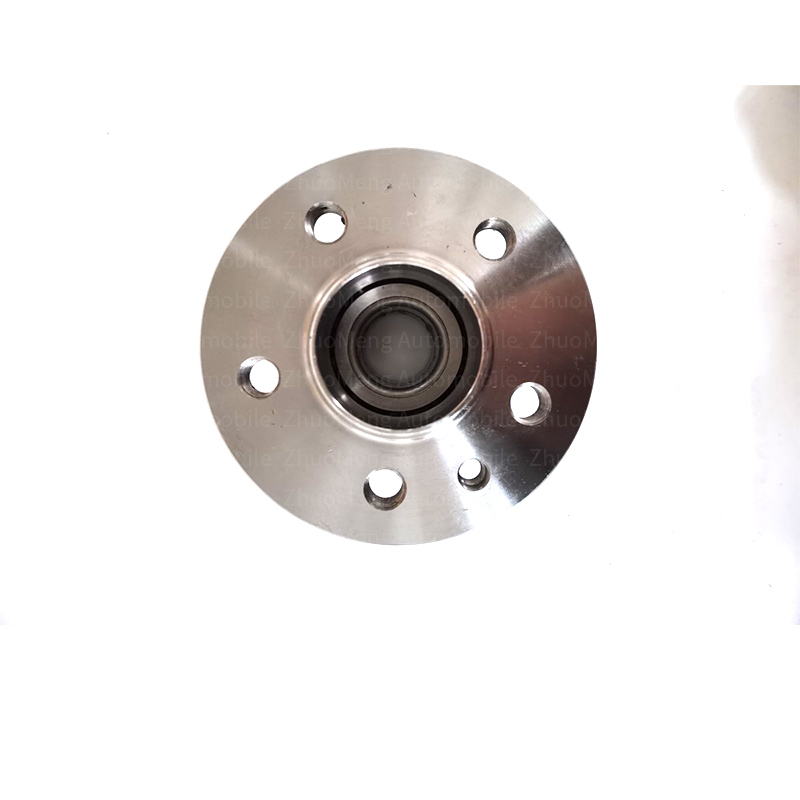

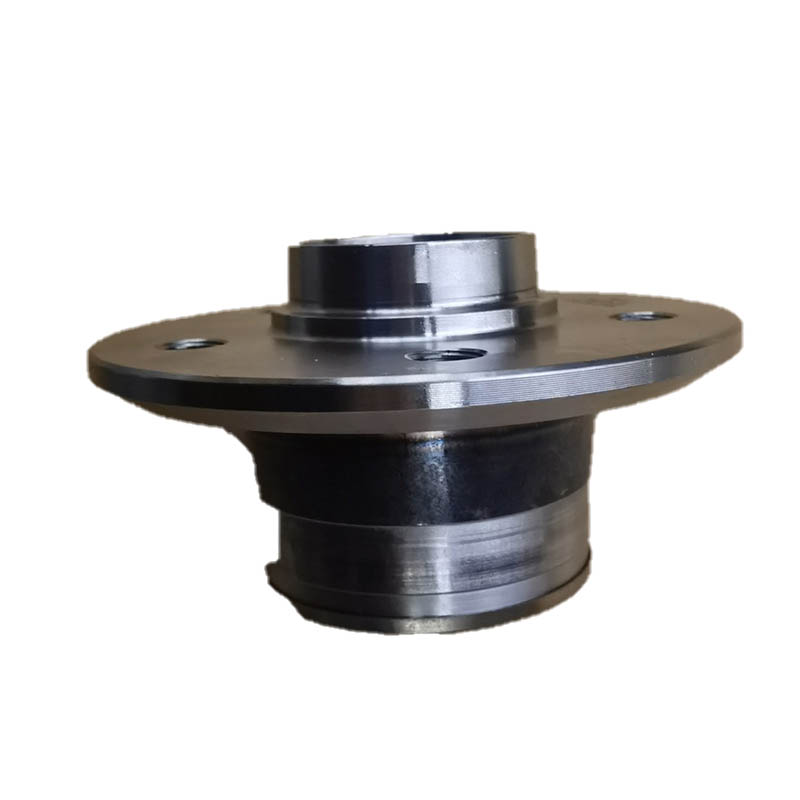

| Products Name | Release Bearing |

| Products Application | SAIC MG 550 |

| Products OEM NO | 10019590 10002285 Dac44825037 |

| Org Of Place | MADE IN CHINA |

| Brand | CSSOT / RMOEM / ORG / COPY |

| Lead Time | Stock, if less 20 PCS, normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application System | Chassis system |

matters needing attention

1. There is a magnetic thrust ring in the sealing ring equipped with ABS device bearing, which can not be impacted, impacted or collided with other magnetic fields. Take them out of the packing box before installation and keep them away from the magnetic field, such as the motor or electric tool used. When installing these bearings, observe the ABS alarm pin on the instrument panel through the road condition test to change the operation of the bearings.

2. For the hub bearing equipped with ABS magnetic thrust ring, in order to determine which side the thrust ring is installed, you can use a light and small thing * close to the edge of the bearing, and the magnetic force generated by the bearing will attract it. During installation, point one side with magnetic thrust ring inward and face the sensitive element of ABS. Note: incorrect installation may cause the function of the brake system to fail.

3. Many bearings are sealed and do not need to be greased throughout their life. Other unsealed bearings, such as double row tapered roller bearings, must be lubricated with grease during installation. Due to the different sizes of the inner cavity of the bearing, it is difficult to determine how much grease to add. The most important thing is to ensure that there is grease in the bearing. If there is too much grease, the excess grease will seep out when the bearing rotates. General experience: during installation, the total amount of grease shall account for 50% of the bearing clearance. 10. When installing the lock nut, the torque varies greatly due to different bearing types and bearing seats.

350 release bearing 10100210

10002285 550 rear wheel bearing

Dac44825037 ABS 550 front wheel bearing

Customer evaluation

Product detail pictures:

Related Product Guide:

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of 2022 wholesale price Mg Classic Parts - MG 550 Collection Of Various Wheel Bearings – Zhuomeng , The product will supply to all over the world, such as: Venezuela, Indonesia, Czech, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!