100% Original Mg Zs Car Accessories - SAIC MG RX5 Rear door handle liner -10196182 – Zhuomeng

100% Original Mg Zs Car Accessories - SAIC MG RX5 Rear door handle liner -10196182 – Zhuomeng Detail:

Products information

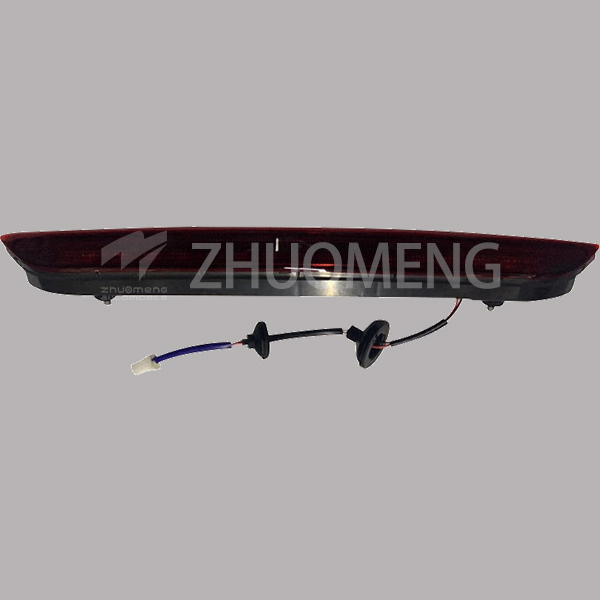

| Products name | Rear handle liner |

| Products application | SAIC MG RX5 |

| Products OEM NO | 10196182 |

| Org of place | MADE IN CHINA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock,if less 20 PCS,normal one month |

| Payment | TT Deposit |

| Company Brand | CSSOT |

| Application system | Body parts |

Products knowledge

The advantage of inertia release method is that the model is simple and does not contain complex body in white. Calculations utilize linear analysis, response and iteration fast. The difficulty is that accurate determination and adjustment in the simulation process need to rely on the support of a large number of historical data and engineers’ development experience, and can not consider the dynamic effect and materials, contact and other nonlinear factors in the process.

Multibody dynamic method

The multi-body dynamics (MBD) method is relatively simple and iterative to evaluate the structural durability of body closing components. The fatigue life can be predicted quickly according to the process and the finite element model of the closing parts as shown in the following figure. In the multi-body model, the locking mechanism of the closing parts is simplified into a rigid body element, the buffer block is simulated by a spring element with nonlinear stiffness characteristics, and the key sheet metal structure is defined as a flexible body. The load of the key contact parts is obtained, and finally the fatigue life of the closing parts is predicted according to the stress-strain and deformation effects.

OUR EXHIBITION

Good Feetback

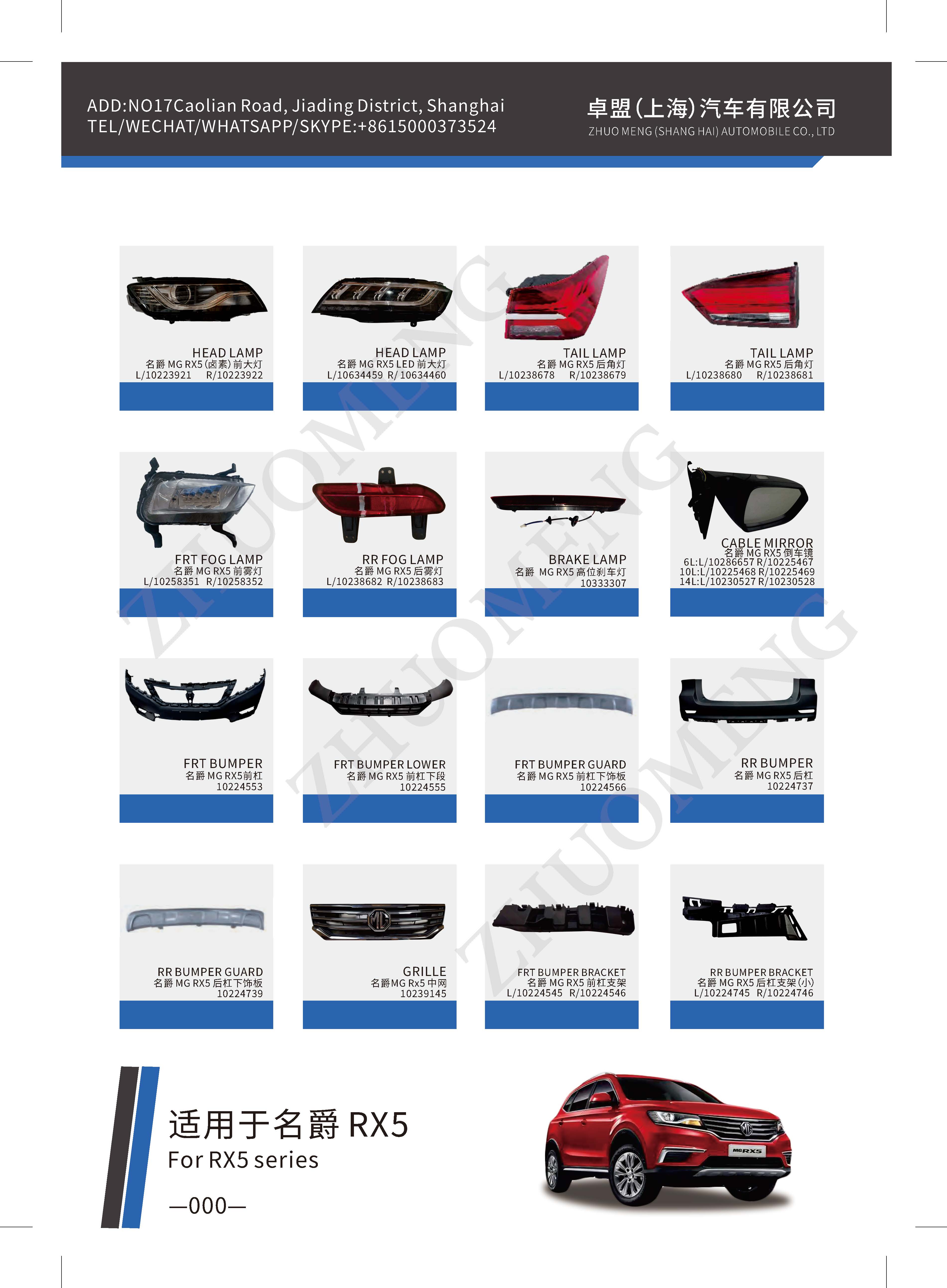

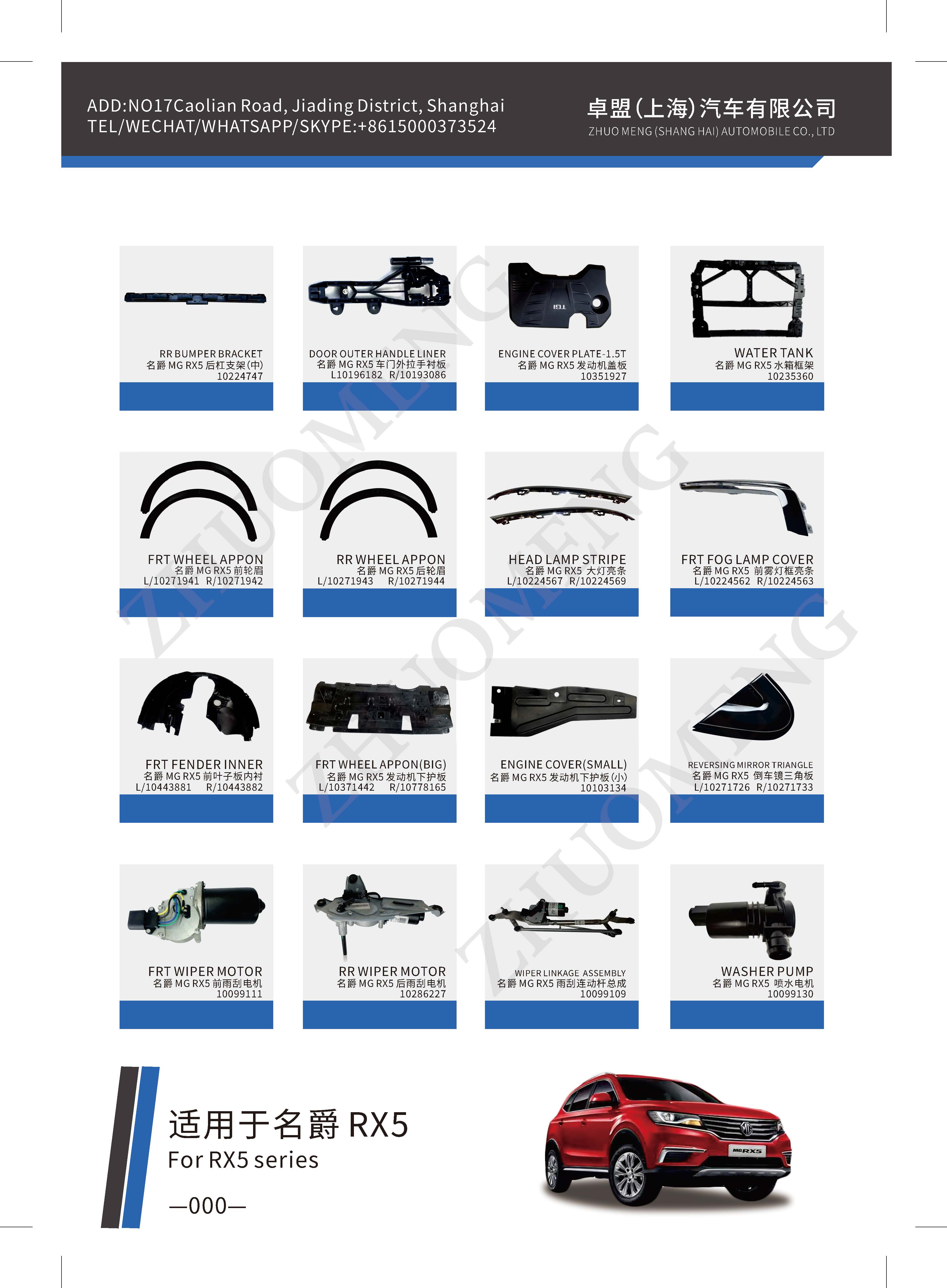

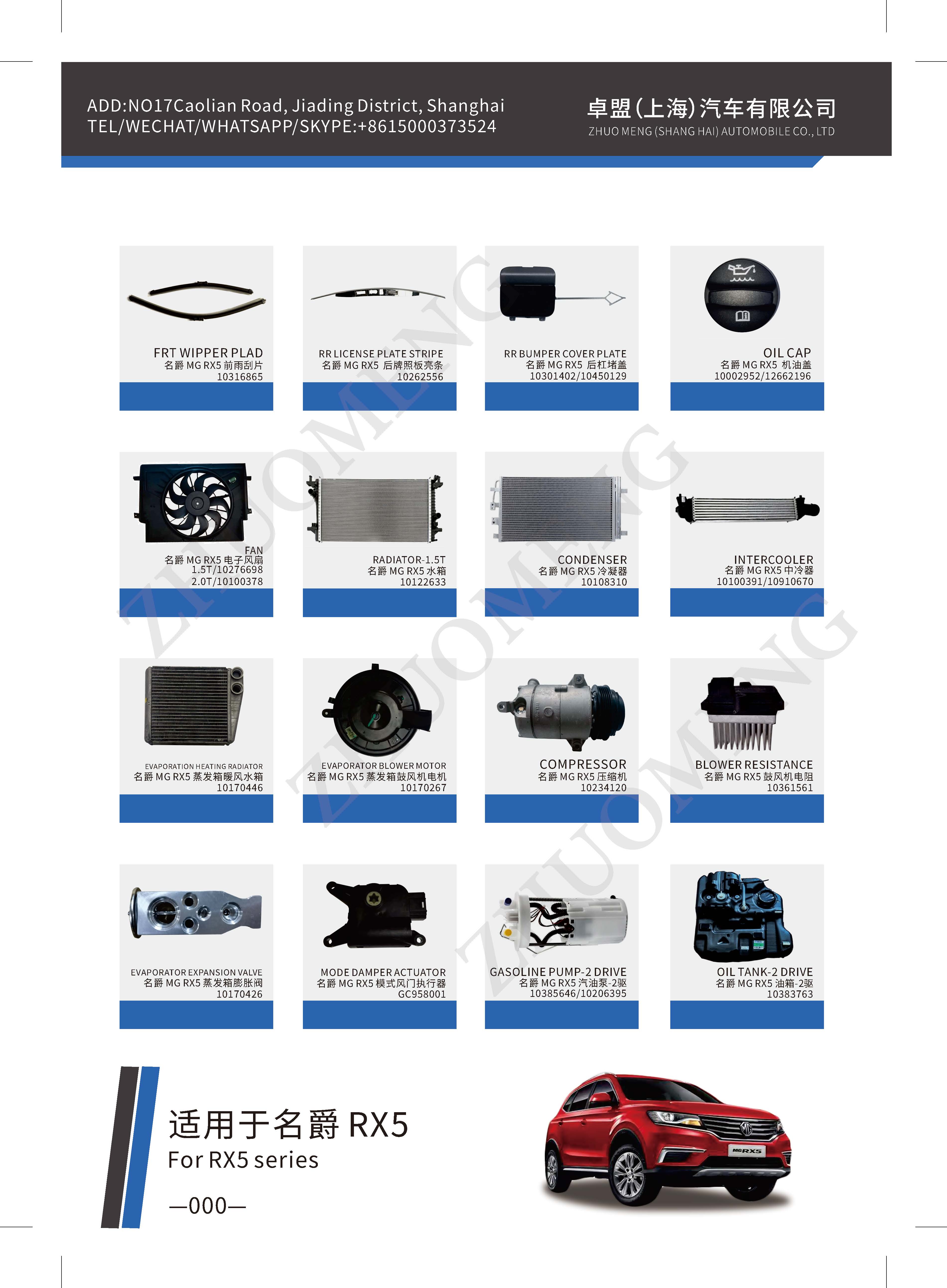

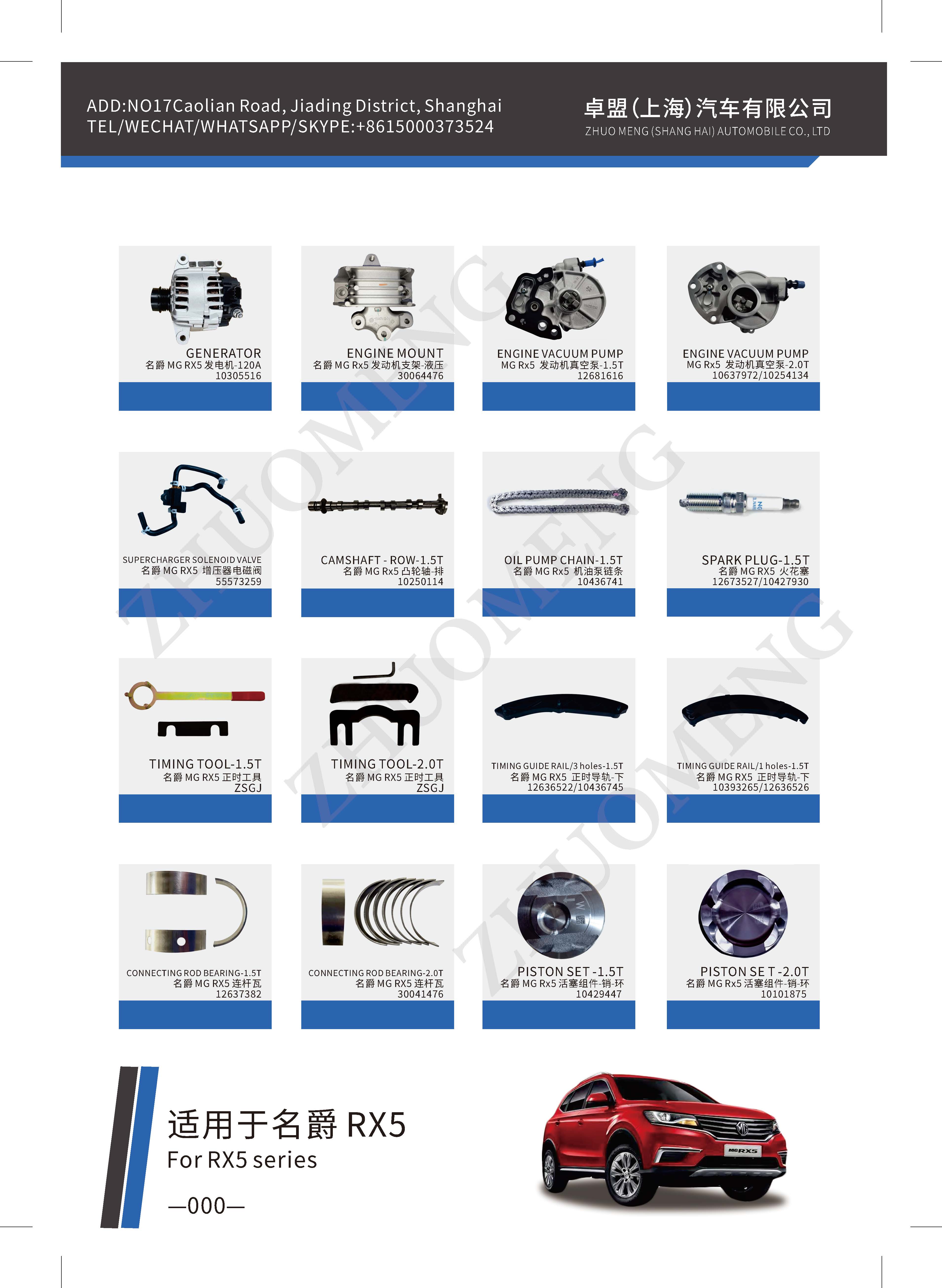

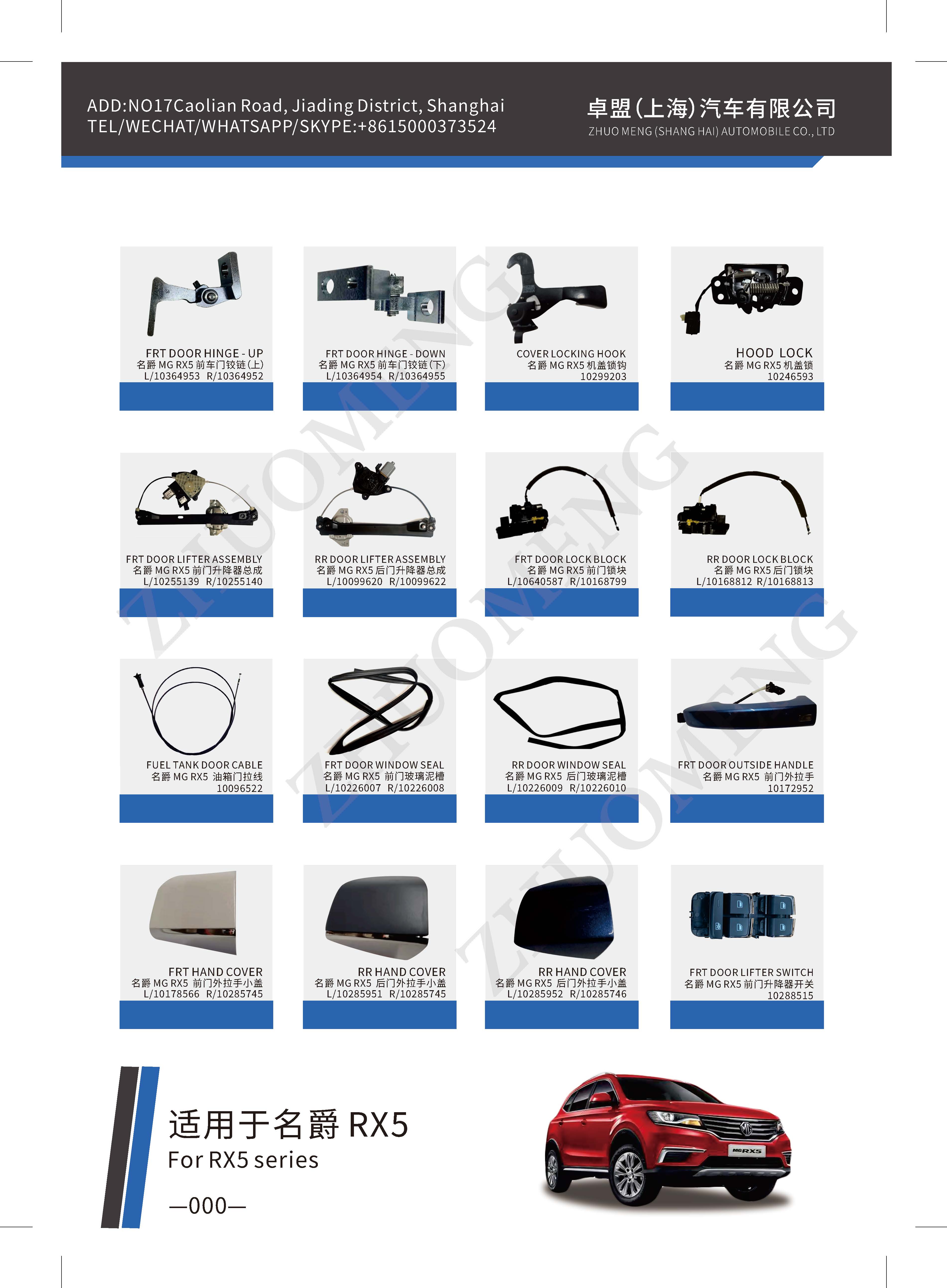

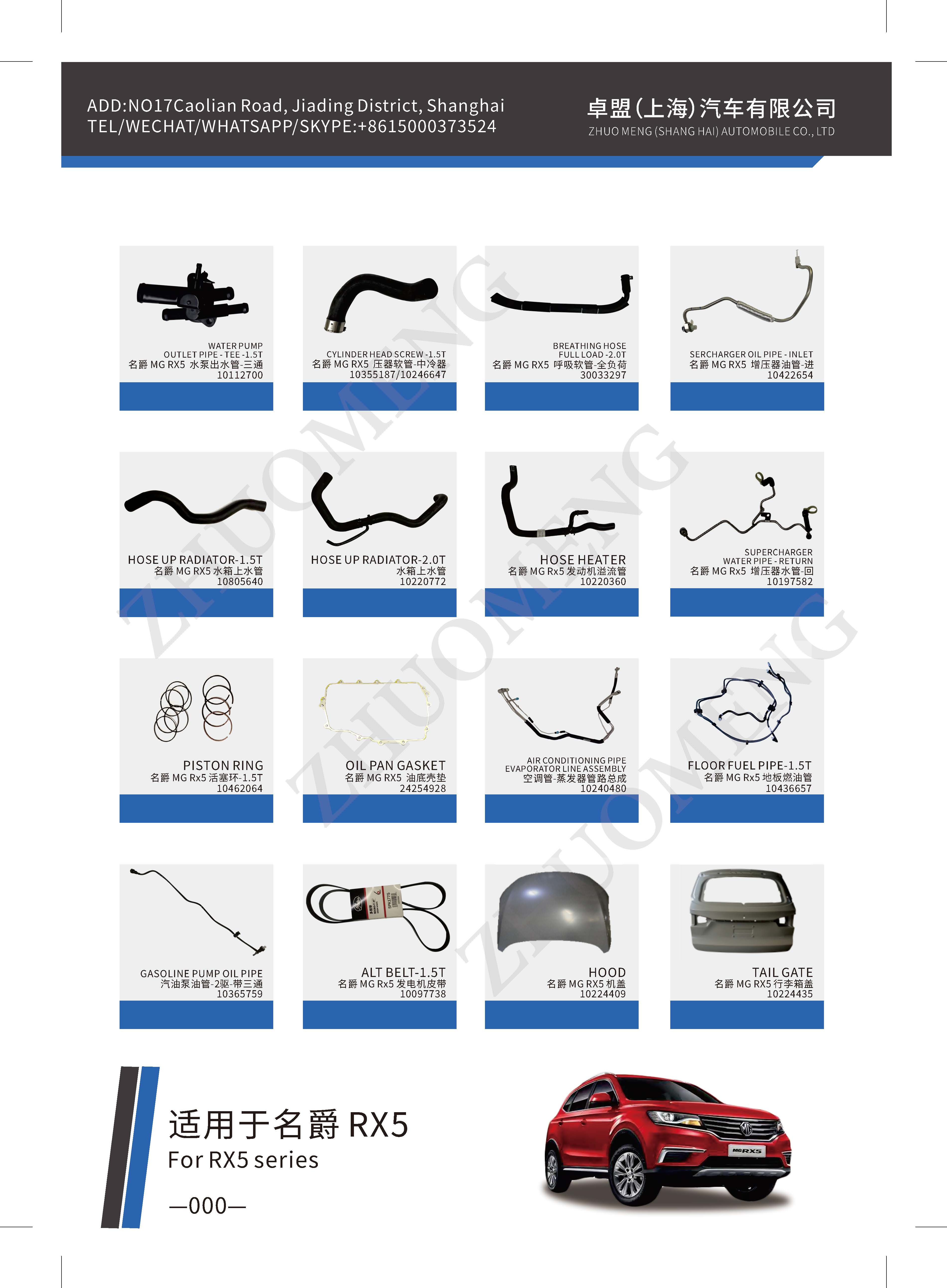

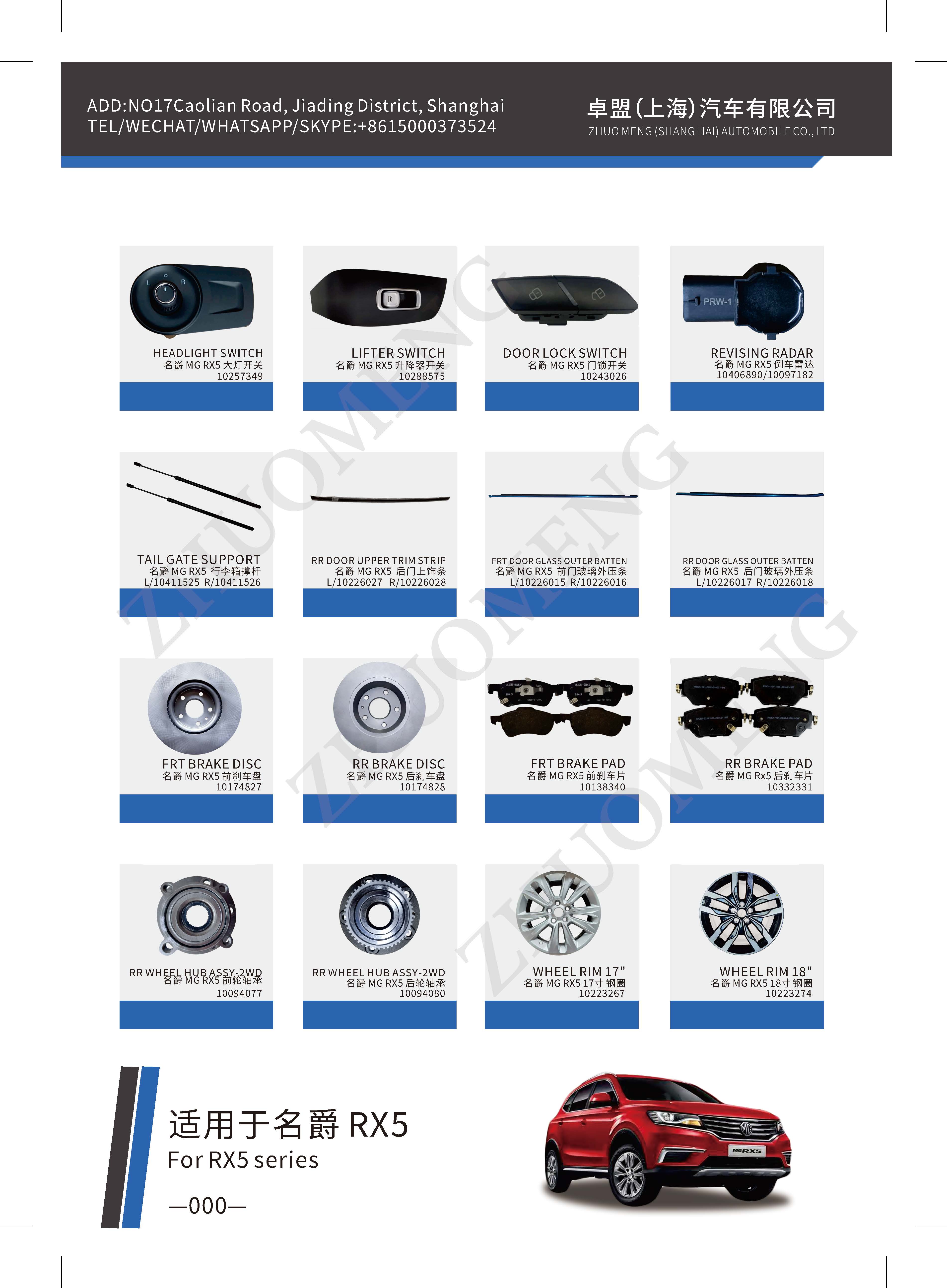

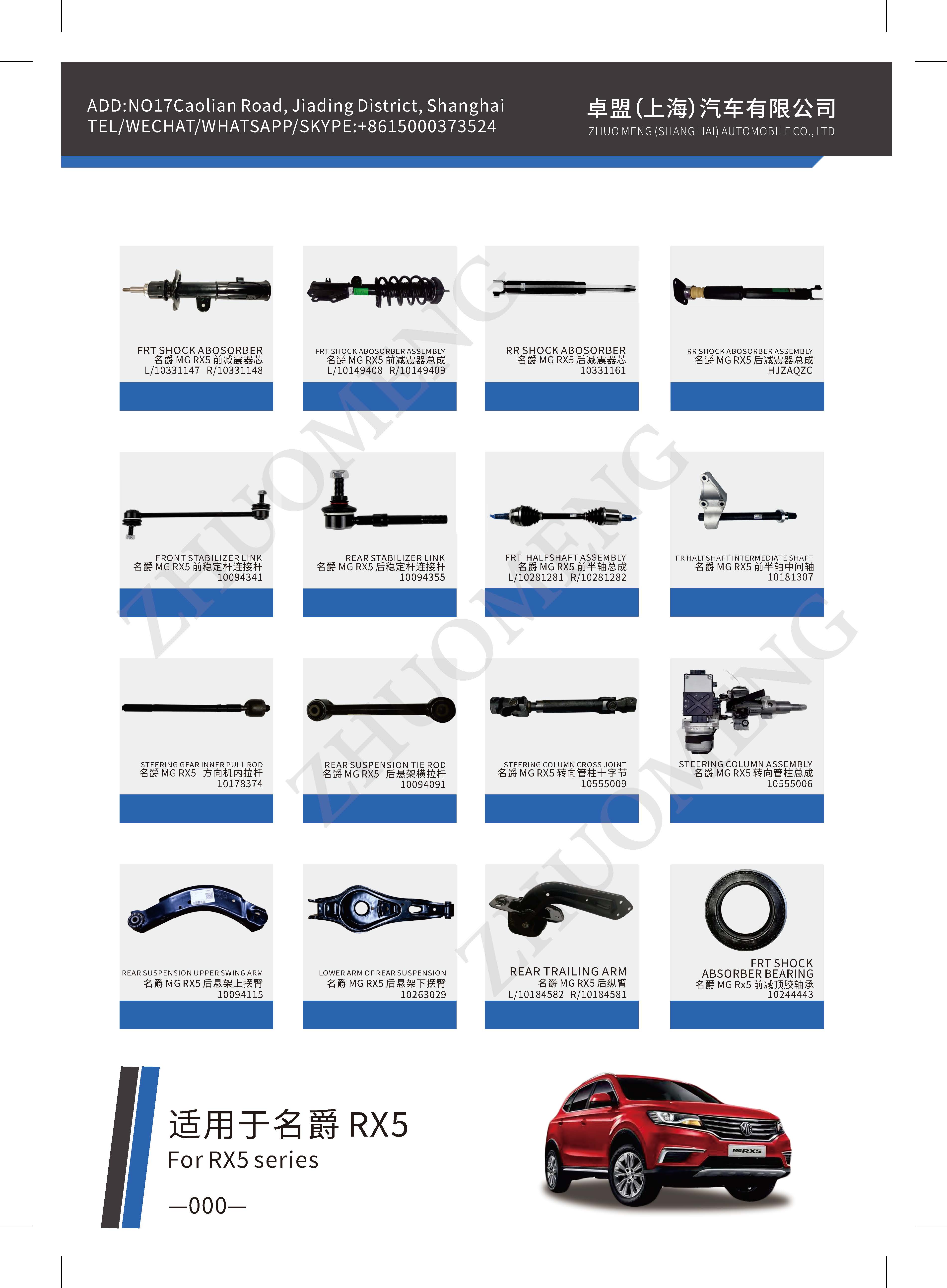

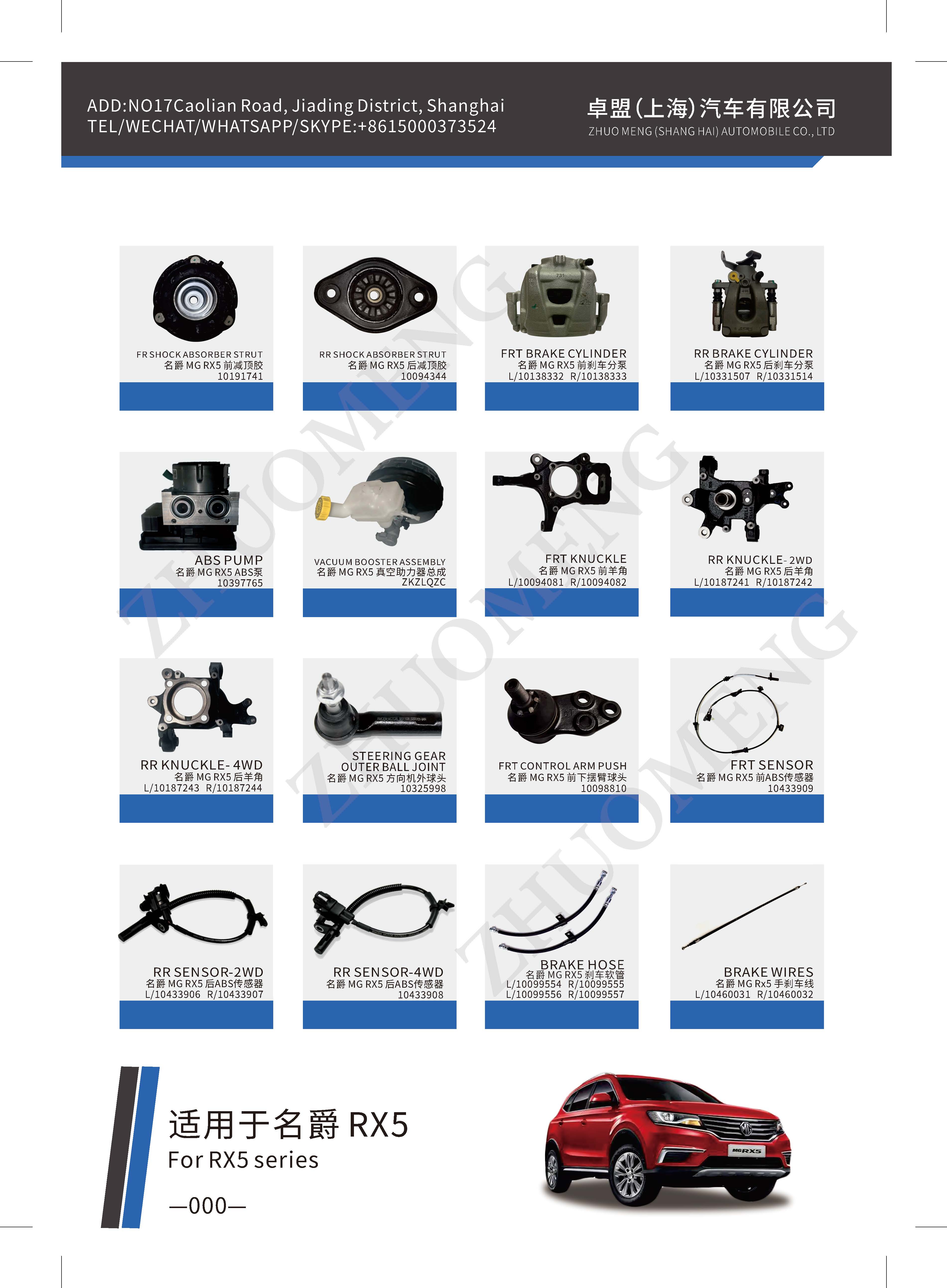

Products catalog

Related products

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for 100% Original Mg Zs Car Accessories - SAIC MG RX5 Rear door handle liner -10196182 – Zhuomeng , The product will supply to all over the world, such as: Armenia, Kuala Lumpur, Austria, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!